LT-S-L Technical manual

★

Note

:

External suction filter should be used for cryogenic refrigeration systems

。

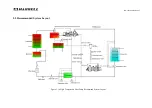

5.1.2

Economizer Piping Layout

1

)

Economizer pipe dimension

A shut-off valve of the economizer is the standard accessory. It's recommended

to design the dimension of the pipes according to Hanbell suggested valve (Refer to

10.2.2 ).

2

)

Economizer check valve

When the operating conditions are unstable or when the economizer loop is

closed, a part of oil and refrigerant will flow back to the economizer pipe. In order to

prevent this phenomenon, this type of compressor is equipped with economic check

valve as standard.

3

)

Economizer intake filter

There is a built-in intake filter in the compressor, which is mainly used for

catching the impurities from the economizer and its pipes during the initial operation

to avoid serious damage to the compressor. This filter is not suitable for regular

cleaning and replacement of filter elements. If the system does have such

requirements, an external filter should be equipped on the economizer pipeline.

5.1.3

Minimum pressure valve

The oil pressure differential of the compressor between high pressure and

medium pressure shall be able to reach 2.5 bar in 30 seconds after start up to ensure

the lubricant can go into the compressor on time.

If the compressor fails to establish the pressure differential, it will cause

insufficient oil supply, leading to compressor shut down even damaging the

compressor.

Therefore, we provide a minimum pressure valve for LT series compressor so as

to achieve the pressure differential between high pressure and middle pressure quickly.

The minimum pressure valve should be mounted after the external oil filter, and

connected to the compressor medium pressure test point.

The location and installation of the minimum pressure valve is shown as below

picture.