LT-S-L Technical manual

Meanwhile, we suggest to install a pressure differential switch to detect pressure

drop before & after the oil filter. If the pressure drop bigger than 1.5 bar, the

compressor must be stopped for cleaning or replacing the oil filter to ensure enough

pressure to deliver the lubricant and cleanliness.

★

Note

:

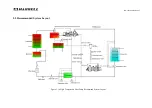

Refer to Figure 5-7 for the layout of oil filter and pressure difference switch.

3

)

Oil pressure differential

This type of compressor relies on the pressure difference of the lubricating oil to

provide oil circulation power. To ensure that the lubricating oil can be continuously

supplied into the compressor when the compressor is running, the oil pressure of the

compressor lubricating oil and the medium pressure of the compressor must be

ensured. There is a pressure difference of more than 2.5 bar in the cavity. Therefore,

Hanbell requires this protection should be added when designing the system

protection.

4

)

Oil level protection

The oil supply to compressor cannot be guaranteed only by the oil pressure

differential, so it is suggested to install an oil level switch to ensure the oil circulation.

5

)

Oil flow protection

To ensure the oil supply and increase the reliability, an oil flow switch is also

suggested to be installed.

★

Note: Refer to Figure 5-7 for oil flow switch installation

2

)

Hanbell provides oil flow switch as an optional (refer to 10.3.1)

5.2.5

Oil cooling system

It is normally used in high pressure ratio working conditions. Under such

working condition, a lot of heat will be generated, and part of the heat will be taken

away by the lubricant, so if additional measures are not taken to cool down the

lubricant, the temperature will be over high, which cannot be able to meet the

conditions of compressor's normal operation

Installing an external cooler is a normal way to solve the problem, which can

make the temperature of the lubricant remain at a certain reasonable range. Sothat the

compressor can work properly even in strict working conditions.

Note:

1

)

It is suggested to install the oil cooler near the cooler.

2

)

When the piping of the cooler is designed, please make sure to avoid the gas