COMPRESSOR INSTALLATION & START-UP GUIDE

REVISION M

12

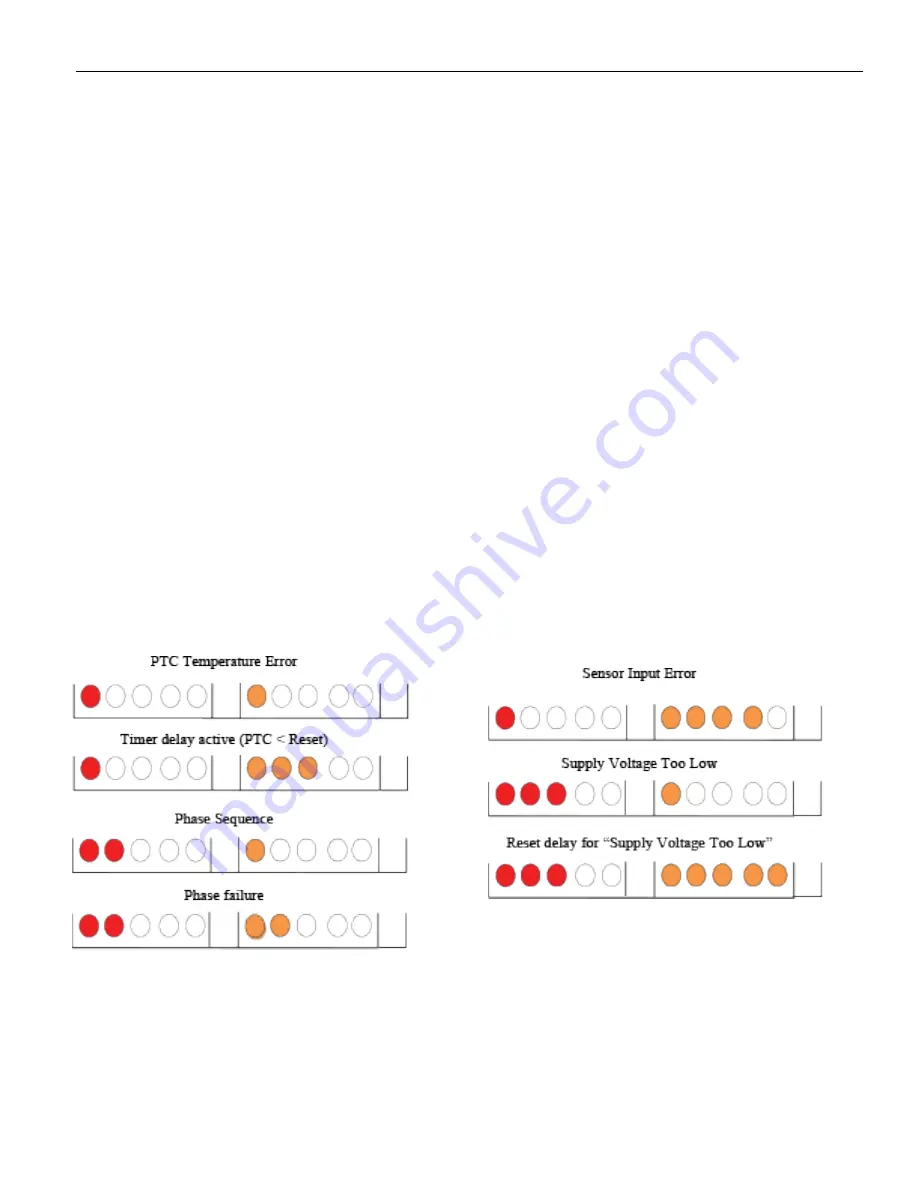

6. Description - INT69HBY DIAGNOSE

Hanbell supplies INT69 HBY Diagnose for motor protection with monitoring functions of phase loss, phase

sequence, motor temperature, and discharge temperature. The module has built in flash codes that are help-

ful for diagnosing safety faults.

In order to protect the compressor, each RC2 series compressor has been built with three PTC temperature

sensors inside the motor coil and one at the discharge port neck of the compressor. These sensors are con-

nected to the motor module to monitor coil temperature and discharge temperature. Up to 9 sensors can be

connected in series and used with one module.

If the temperature in one of the positions monitored exceeds nominal response temperature of the respective

PTC thermistor (230° F, 4.5 ohms ±20%), the sensor resistance increases and the module trips (M1 and M2

open). The failure results in a lockout. The module resets when the response temperature drops 3k

Ω

(when

temp

decreases below 212°F, 2.75 ohms ±20%). 5 min delay for the first PTC failure, 60 min delay for the 2

nd

fail-

ure, latching lockout for the 3

rd

within 24 hour period. Monitoring is inactive for 20 seconds after motor stop

to prevent nuisance trips from brief reverse rotation.

Phase failure (loss) and Phase sequence safety trips result in a first time lockout. Phase sequence monitor-

ing is active 1 second after motor start for 10 seconds. Phase loss is monitored 1 second after motor start till

motor stop.

Lockout and time delay can be cancelled by interrupting power to the module for 5 second’s. An optional

power supply reset button can be added to electrical connection box.

Flash Codes

RED

ORANGE

RED

ORANGE