38

Hanbell Maintenance

Version 1.0

and welding slag might find its way to compressor’s suction side. With the help of the suction strainer, debris

will be gathered inside the strainer to protect the compressor from rotor damage. Technicians should check the

suction strainer at the

end of commissioning and after 200 hours of initial running

. Any dirt and unwanted

material should be removed during the checking. Wash the strainer basket in solvent and blow clean with air.

1.2.2

Oil Analysis

At the

end of commission or after 200 hours of initial running

, oil analysis is recommended to be executed

at jobsite. The purpose of doing oil analysis is to understand the compressor’s working environment and

ensure the oil quality. If moisture contamination exists in the system, this will lead to changing of oil quality

and cause poor lubrication for internal moving parts which can cause severe damage to the compressor in

the future. Technicians should replace the oil immediately to protect the internal moving parts with good

lubrication and recheck the oil

again after 200 hours operation

. If the oil analysis shows the oil is in good

condition,

recheck the oil every 6months

to ensure the condition remains safe.

In the case of being unable to do the oil analysis periodically, consult Hanbell oil change schedule because

the interval of oil change varies by the oil type and compressor operating condition.

Check the oil acidity periodically and change the oil if the oil acidity value measures lower than pH6.

1.3.

Long Term Maintenance

The information below is focusing on standard long term maintenance. Technicians should understand that

these items are not assumed to take over all the necessary routine checks. Daily check for operation conditions

is also very important to have a stable operating system.

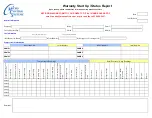

Please refer to the recommended maintenance schedule found on the following pages. This schedule is only

for the technician’s reference and should be considered as the minimum guideline to maintain the system’s nor-

mal operation. Technicians still can do any examination by their own that will ensure a stable system

operation. In case of any irregular situation or abnormal condition that takes place on the compressor

system, Technicians should stop the compressor and contact the contractor who installed the unit.

1.3.1

Mechanical Seal

The Shaft seal leakage should be observed everyday and be inspected by removing the cover at least once

per year when doing other regular maintenance. Special attention should be given to hardening and cracking

of the O-ring, wear, scoring, material deposits, oil coke and copper plating. The purpose of checking the

mechanical seal every year is to ensure the stable operation for the following year. Wearing parts of shaft

seal are recommended to be changed with a new one.

1.3.2

Piston Sealing

The Piston is also recommended to be inspected every year to ensure the function of capacity control. If

abnormal wearing is found, the corresponding part should be replaced by a new one. Prior to replacing, the

technicians should do an inspection and determine what is causing the wearing problem.

1.3.3

Vibration Analysis

Vibration analysis can help to detect bearing wear and other mechanical failures. A certified Hanbell Technician

should perform this check.

Overhaul Review

Overhaul review is recommended to be done at least

every 3 years

. It is the best time to review the internal parts

and replace all wearing parts for the following long-term operation. A certified Hanbell Technician should

perform this review.

Supersedes all other warranties prior to 6-28-2019