30

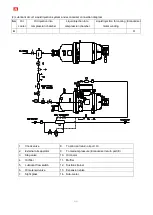

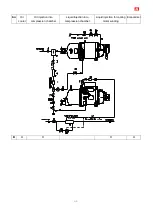

2.4 Capacity control system

The RC2-F series screw compressors are equipped with either 3-steps/4-steps or continuous (step-less) capacity

control system. Both capacity control systems consist of a modulation slide valve, piston rod, cylinder, piston and

piston rings. The slide valve and the piston are connected by a piston rod. The principle of operation is using the oil

pressure to drive the piston in the cylinder. The lubrication oil flows from the external oil separator through the oil

filter to the main oil inlet port and then fills into the cylinder due to the positive oil pressure force which is bigger

than the spring force plus the force from high pressure gas. The positive pressure differential causes the piston to

move toward the loading direction in the cylinder. When the slide valve moves toward the loading direction, the

effective suction volume increased in the compression chamber. This means the displacement of refrigerant gas

also increases, as a result the refrigeration capacity also increases. However, when any of the step solenoid valve

(for 4-step capacity control system) is opened, the high pressure oil in the cylinder bypasses to the suction side,

which causes the piston and the slide valve move toward the unloading direction, and then some of the refrigerant

gas bypasses from the compression chamber back to the suction end. As a result, the refrigeration capacity

decreases because of the reduction of displacement of refrigerant gas flowing in the system.

The piston spring is used to push the piston back to its original position, i.e. minimum load position in order to

reduce the starting current for the next starting-up. If the compressor started at full load capacity it may result in

over current start. The modulation solenoid valves are controlled by a micro controller or temperature switch to

modulate the piston position smoothly with stable output of capacity.

If the oil filter cartridge or modulation solenoid valves are not working well in the capacity control system, this may

result in the abnormality and ineffectiveness of the capacity control system. Before stopping the compressor,

HANBELL strongly recommends that the unloading solenoid valve of step-less control system or minimum load

solenoid valve of 3/4 steps control system should be kept opened for 30~60 seconds so that oil pressure in the

cylinder can be released. When starting the compressor next time, the slide is at its minimum load position for a

light duty start.

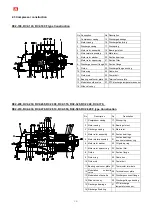

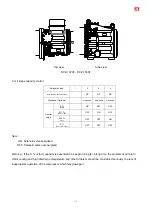

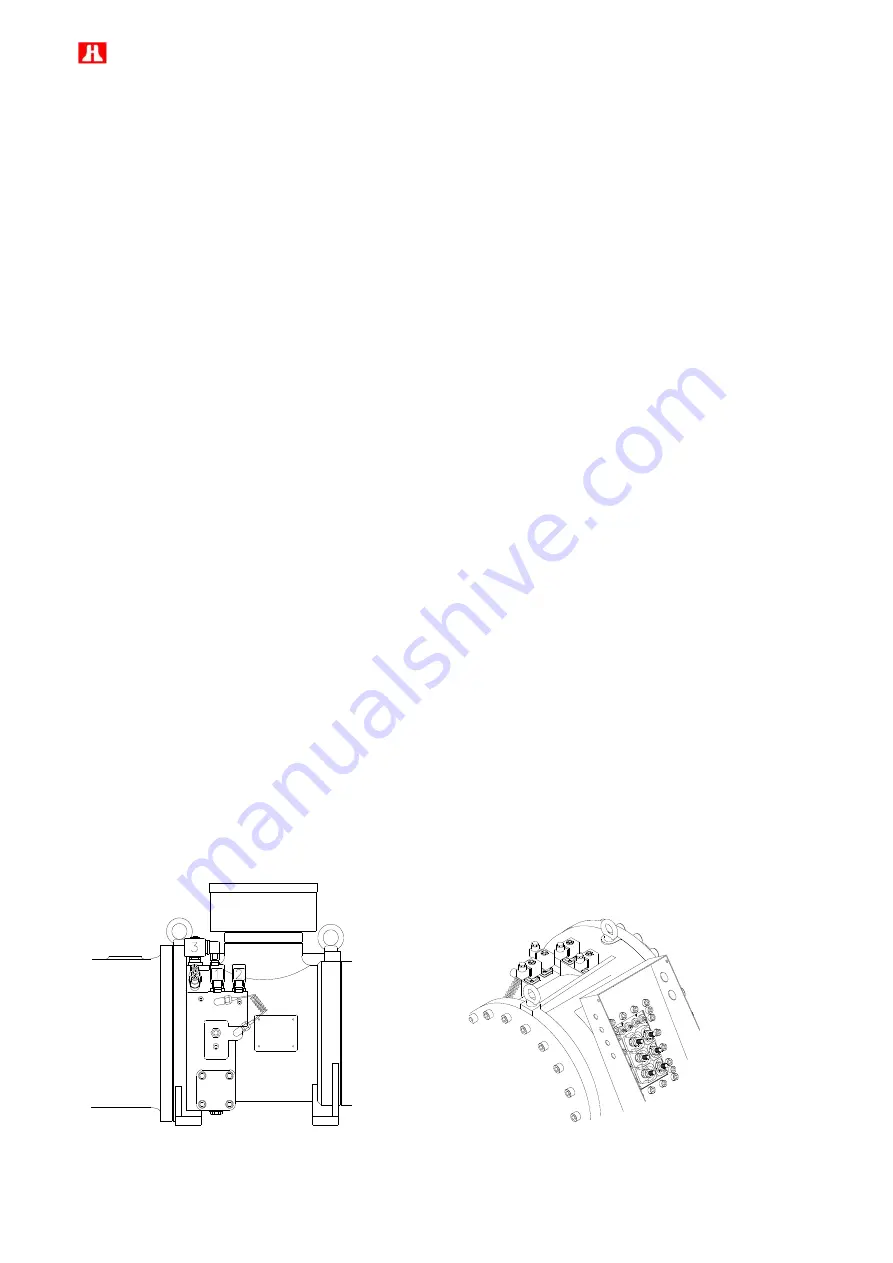

The capacity control solenoid valves of different models are equipped as the pictures shown below. Please refer

to the pictures and description for the detail of capacity control logic.

1

2

4

3

RC2-100F/140F/180F RC2-200F~RC2-930F

Summary of Contents for RC2-F Series

Page 6: ...5 2 2 Compressor outline...

Page 7: ...6...

Page 8: ...7...

Page 9: ...8...

Page 10: ...9...

Page 11: ...10...

Page 12: ...11...

Page 13: ...12...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

Page 85: ...84 Horizontal External Oil Separator OS80 Horizontal External Oil Separator OS100 OS125 OS150...