65

2. For the chiller system using synthetic oil, make sure not to expose the oil to atmosphere for a long time. It is

necessary to vacuum the system completely when installing the compressor.

3. If the customer wants to use special type of oil, confirm with the compressor manufacturer is necessary.

4. In order to vaporize the water in the system, it is suggested to heat the system and vacuum the system as long

as possible after changing of new oil in the system

5. If the system encounters a compressor motor burned, the acidity debris will remain inside the system, so follow

the procedures mentioned above to overhaul the system is necessary. It is also important to check the oil acidity

after 72 hours operation and change it again until the oil acidity is within the standard value.

4.2 Changing of oil

Lubrication oil is one of the most important factor to the compressor system in order to maintain the good

operation, lubrication, cooling, sealing and capacity control. The following points should be taken into

consideration to ensure good oil management.

1. Oil contamination caused by debris or swarf might clog the oil filter and cause compressor bearing failure. In

order to prevent the clogging of oil filter, an optional pressure differential switch is recommended to be installed.

The switch will trip when the oil pressure differential reaches the setting point. The compressor will shut down

automatically to prevent the bearing away from getting damage by lacking of lubrication.

2. Acidified system due to the moisture will cause

the reduction of bearing and motor’s life. Check the oil acidity

periodically and change the oil if the oil acidity value is lower than PH6. Change the deteriorated dryer periodically

if possible to keep the system dryness. Refer to the oil changing procedure especially after overhauling the

system due to motor burned out, check the oil quality monthly or periodically and change the oil if the oil is out of

standard specs. It is necessary to take care of the oil quality and system cleanliness and dryness periodically.

3. Compressor running at high discharge temperature for a long time will cause the change of oil property and

short the bearing life. If the compressor

’s discharge temperature keeps at high stage (approaching the critical

point) then the oil will spoil gradually in a short time. Check the oil characteristic every 2 months if possible. It is

necessary to change the oil if the characteristics of the oil are out of the specification. In case if the oil

characteristics cannot be checked periodically, change the oil after 1 years of operation. For the first operation of

the compressor, it is recommended to check oil and clean oil filter after running 200 hours. Because the piping

debris or swarf could be accumulated inside the system after continuous operation, it is necessary to check the oil

after 2,000 hours or after 6 months of running. Good oil management can ensure the system operating under

good condition.

Summary of Contents for RC2-F Series

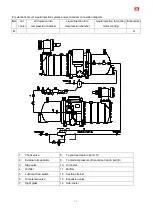

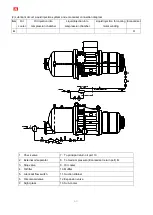

Page 6: ...5 2 2 Compressor outline...

Page 7: ...6...

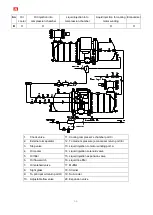

Page 8: ...7...

Page 9: ...8...

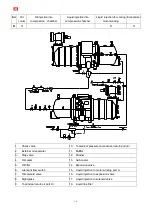

Page 10: ...9...

Page 11: ...10...

Page 12: ...11...

Page 13: ...12...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

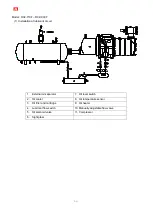

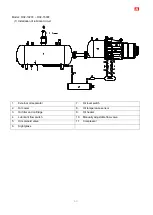

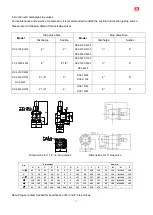

Page 85: ...84 Horizontal External Oil Separator OS80 Horizontal External Oil Separator OS100 OS125 OS150...