85

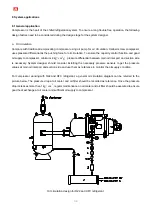

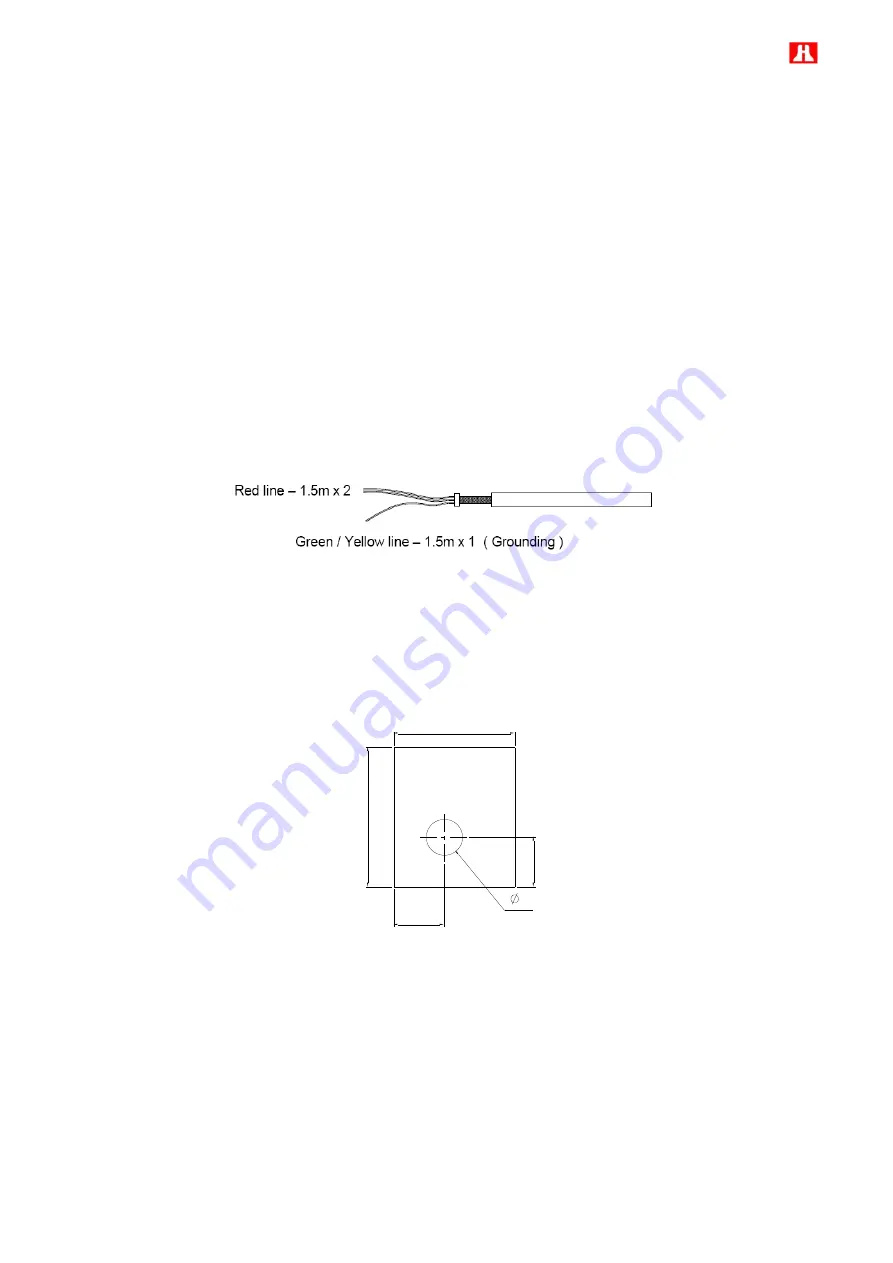

m. Oil heater

Oil heater is used to maintain the oil temperature in the oil separator during shutdown cycles. It can help to get a

safe start-up especially when the ambient temperature is low. Oil heater should be energized only when the

compressor unit is not in operation and should not be energized when there is no oil in the reservoir. The selection

of oil heater depends on total quantity of oil.

Before restart of compressor after shutdown for a long time, please turn on oil heater at least 8 hours to make the

temperature inside compressor higher than system temperature and ambient temperature and then it can prevent

condensation of refrigerant inside oil sump of compressor which may result in liquid compression in next start and

poor lubrication due to too low viscosity. In addition, Hanbell also offers 300W oil heater to keep adequate

lubricant temperature for large external oil separator and applications in areas with low ambient temperature.

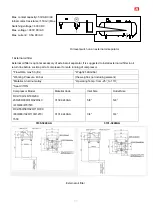

Specification : 150W, 300W, 110V or 220V, IP 54, UL approval

150W , 300W oil heater

n. Mounting pad

To avoid extra vibration and noise resulted from direct contact between compressor footings and the base on

which compressor is mounted, it is recommended to add mounting pads in between as the drawing below shown.

A

E

B

C

D

Summary of Contents for RC2-F Series

Page 6: ...5 2 2 Compressor outline...

Page 7: ...6...

Page 8: ...7...

Page 9: ...8...

Page 10: ...9...

Page 11: ...10...

Page 12: ...11...

Page 13: ...12...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

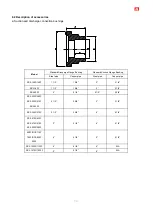

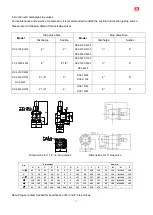

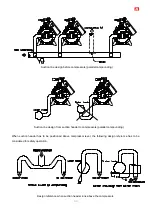

Page 85: ...84 Horizontal External Oil Separator OS80 Horizontal External Oil Separator OS100 OS125 OS150...