91

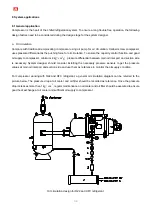

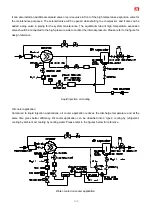

compressor. User should use suction pressure as reference and make sure the valve opened when the discharge

pressure is 4

2

/

cm

kg

higher than the suction pressure. This is essential especially in the low condensing

temperature condition.

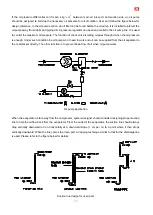

7.3 Compressor stop

Compressor stop should be executed under regular procedure. The controlling program should unload the

compressor gradually to its minimum capacity and stop the compressor after it reaches the minimum load. Oil line

solenoid and oil pump (if apply) should be closed at the same time when the compressor stops. ECO line should

be closed when the slide valve position is below 50%. Oil/Liquid injection line should be closed 3 to 5 seconds

before the compressor stop. For the first start-up, check and clean the suction strainer and oil filter after the

commissioning is very important to ensure the future operation.

In case of emergency stop, the oil/liquid injection line, oil line, and ECO line should be closed immediately. If

discharge bypass line is designed in the system, it should be opened to balance the pressure differential between

high and low pressure side then close itself for the next running. With the help of suction check valve and

discharge bypass line, the reverse running time can be limited to a few seconds. If the reverse running doesn

’t

stop in about 10 seconds, the leakage at suction check valve and the malfunction of discharge bypass line can be

assumed, User should check them during the stop of compressor. Before starting the compressor next time, user

should correct the problem first then energize all solenoid valves to help the slide valve back to its initial position.

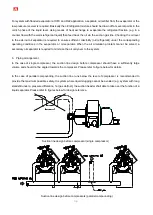

For a short period of non-operation, the oil heater power should be kept on to keep the oil temperature at proper

temperature for the next start up.

For a long period of non-operation or overhauls, the power source for main and oil pump should be cut off. The oil

heater power should be switched off, too. The control panel should be kept power on to resist moisture. All the

stop valves related to the system should be closed. Cooling water supply should be stopped and the cooling water

in the condenser and oil cooler must de drained completely.

Note: Start and stop of compressor should not be repeated more than 4 times per hour.

Summary of Contents for RC2-F Series

Page 6: ...5 2 2 Compressor outline...

Page 7: ...6...

Page 8: ...7...

Page 9: ...8...

Page 10: ...9...

Page 11: ...10...

Page 12: ...11...

Page 13: ...12...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

Page 85: ...84 Horizontal External Oil Separator OS80 Horizontal External Oil Separator OS100 OS125 OS150...