64

4. Lubricant

The main functions of the lubrication oil in the screw compressor are lubrication, internal sealing, cooling,

silencing and capacity control. The positive oil pressure in the cylinder pushes the piston and the slide valve which

are connected by a piston rod to move forward and backward in the compression chamber. The design with

positive pressure differential lubrication system in the RC2-F series is available to omit an extra oil pump in most

of applications. However, in some special applications (Pd-Ps<4 bar), it is still necessary to install an extra oil

pump to the compressor for safety.

Bearings used in RC2-F compressor require a small but steady quantity of oil for lubrication; the oil injection into

the compression chamber creates an oil sealing film between screw rotors which secures the volumetric efficiency

and absorbs a part of compression heat. In order to separate the oil from the refrigerant or gas, an oil separator is

required to ensure the least amount of oil carried into system. High oil carryover to the system will reduce the heat

exchanger performance or simply block the pipe. For synthetic oil, it has high tendency to react with water, acid

and metal particle and generates slurry. Compressor operates without sufficient oil supply will lead to high

discharge temperature, bearing failure or screw rotor jam. Pay more attention to the oil temperature, which has a

very significant factor to the compressor

’s bearing life. High oil temperature will reduce the oil viscosity and cause

the poor lubrication and heat absorption in the compressor as well. Too much refrigerant dissolved in the oil will

also reduce the oil viscosity which might become the root cause of bearing failure in the future. The oil viscosity is

recommended at 10

s

mm

/

2

at any temperature. If the compressor operates under the critical working

condition(low evaporating temperature/high condensing temperature), an extra oil cooler will be needed.

High viscosity oil is recommended to be applied in the strict working condition (heat pump/ air-cooled). User

should take notice on the oil level in the oil separator because if the oil return from the evaporator is less than the

oil carryover to the system from oil separator, the oil separator will loss oil gradually and comes to the system stop

in the end. Therefore, when users find oil return problem in the system, a fine oil separator is highly recommended

to be installed between the oil separator discharge port and condenser. Flooded chiller or DX type chiller with long

distance piping is also recommended to be installed with a fine oil separator to reduce the oil carryover into

system.

Low viscosity oil is recommended to be applied in the low evaporating temperature (SST< -20

℃

). Selecting an oil

which can maintain at least 10 cSt for its viscosity under operating. Miscibility of oil with refrigerant is usually an

important index for the selection of oil. The oil with good miscibility with refrigerant should have low miscibility

value at high working temperature and high miscibility value at low working temperature to ensure the oil viscosity

not declined too much at different working condition.

4.1 Pre-cautions in changing of oil

The following points should be noted to ensure good oil characteristics:

1. Use only qualified oil and do not mix different brand of oil together. Different kinds of refrigerant should match

different kinds of oil, note that some synthetic oil are incompatible with mineral oil.

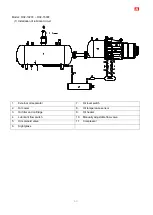

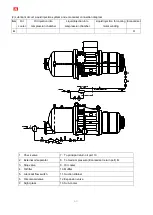

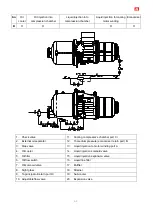

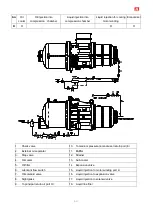

Summary of Contents for RC2-F Series

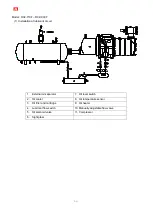

Page 6: ...5 2 2 Compressor outline...

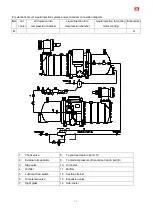

Page 7: ...6...

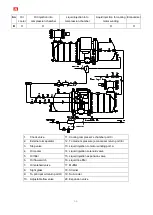

Page 8: ...7...

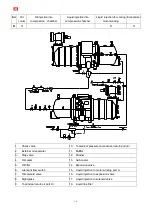

Page 9: ...8...

Page 10: ...9...

Page 11: ...10...

Page 12: ...11...

Page 13: ...12...

Page 14: ...13...

Page 15: ...14...

Page 16: ...15...

Page 17: ...16...

Page 18: ...17...

Page 19: ...18...

Page 20: ...19...

Page 21: ...20...

Page 22: ...21...

Page 23: ...22...

Page 24: ...23...

Page 25: ...24...

Page 26: ...25...

Page 27: ...26...

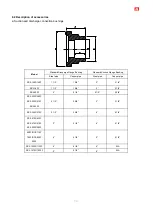

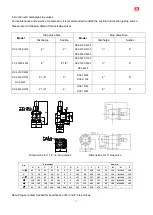

Page 85: ...84 Horizontal External Oil Separator OS80 Horizontal External Oil Separator OS100 OS125 OS150...