Technical Manual

VERSION 2.0 -10-18-2018

11

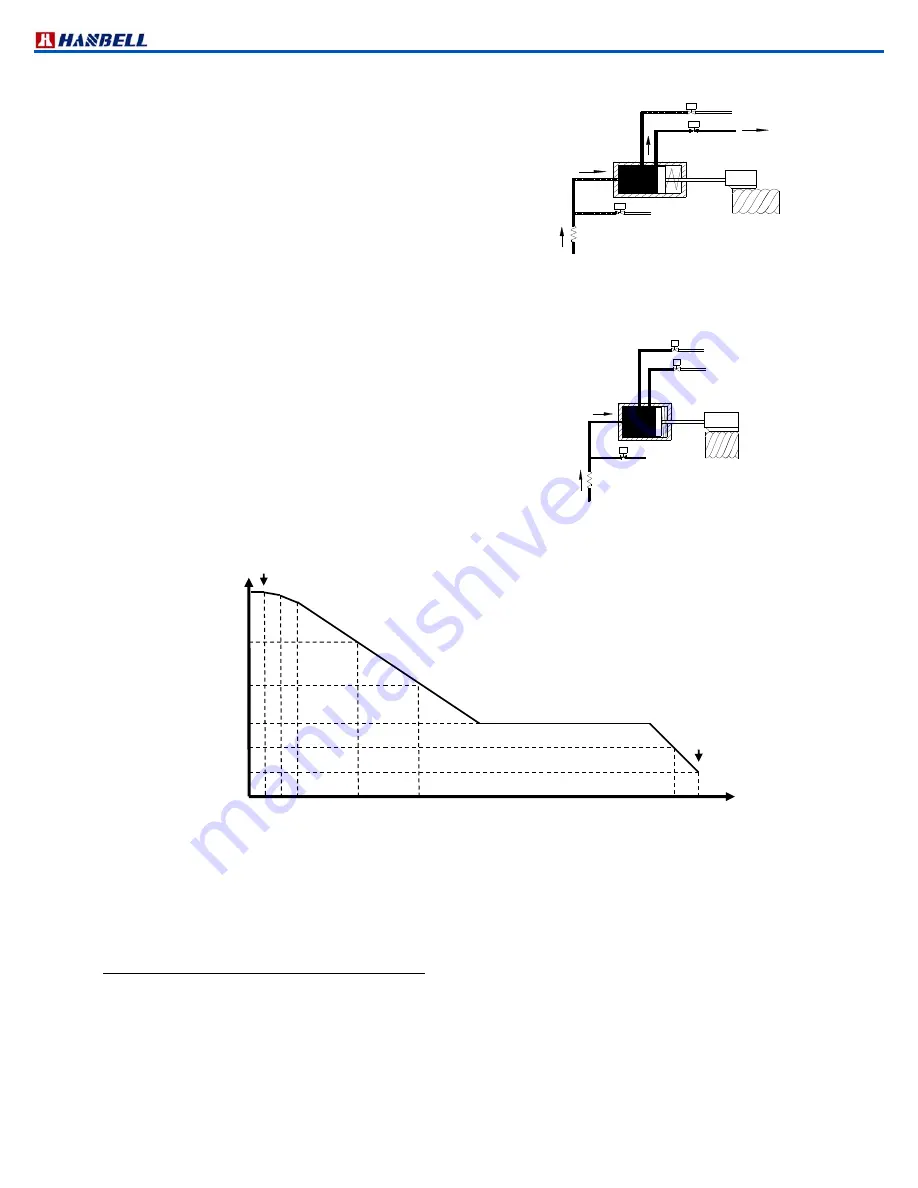

c. 75%/66% capacity

When SV75%/66% solenoid valve is energized, SV50% solenoid valve

will be deenergized simultaneously, the high pressure oil will push the

piston toward the position where a hole at exactly 75%/66% position

drains the oil back to the suction side and the piston will be held on

that position.

d. 100% full load

When all of two/three modulation solenoid valves are deenergized,

the highpressured oil flows into the cylinder continuously to push the

piston toward the suction side gradually until the slide valve touches

the end of the compression chamber and the piston also reaches its

dead end entirely where no bypass of compression gas occurred.

Therefore, full load is achieved.

※

It is strongly recommend to start /stop compressors as per above illustration

Note: 1. Above T & T' should be determined by system designer’s experience and end user’s application.

2. Above t1 & t2 should be longer than 60 sec as recommended.

3. Capacity control must be kept at min% capacity for 1~3 min before start and for 60~90 sec before stop.

4. Start the compressor at min% and SV50% can be energized right after start.

2.8 Continuous (stepless) capacity control system

In continuous (stepless) capacity control system, solenoid valve SV2 (for loading) and solenoid valve SV1 (for

unloading) are equipped to inlet and outlet of piston cylinder respectively. These two solenoid valves are controlled by

chiller temperature controller or micro controller so refrigeration capacity can be modulated anywhere within min% ~

100%. Min% is recommended for start and stop only, not for longtermed operation.

It is very important for any controller to control loading and unloading in stable condition. For a smooth modulation,

HANBELL installs a capillary in loading oil line and an additional orifice valve in unloading oil line to avoid too fast

loading and unloading.

50%

Time

Start

Set point + 2T

Set point + T

Set point (target)

Set point – T

'

Stop

Chilled Water Temp

.

Figure 13.

Start / stop sequence and temperature / modulation of single

compressor

50%(66%)

75%(66%)

100%

t1 t2

75%

(66%)

min%

1

~

3

min

min%

60~90 sec

SV50% OFF

(omitted for RC2100, 140 & 180)

SV75%/66% ON

SV25%/33% OFF

Figure 11 75%/66% Capacity

SV50% OFF

SV75%/66% OFF

SV 25%/33% OFF

Figure 12 100% (Full load)

Capacity

Summary of Contents for RC2 Series

Page 24: ...Technical Manual VERSION 2 0 10 18 2018 24 UNIT SI mm Imperial in UNIT SI mm Imperial in ...

Page 25: ...Technical Manual VERSION 2 0 10 18 2018 25 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 26: ...Technical Manual VERSION 2 0 10 18 2018 26 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 27: ...Technical Manual VERSION 2 0 10 18 2018 27 UNIT SI mm Imperial in ...

Page 28: ...Technical Manual VERSION 2 0 10 18 2018 28 ...

Page 29: ...Technical Manual VERSION 2 0 10 18 2018 29 UNIT SI mm Imperial in ...

Page 30: ...Technical Manual VERSION 2 0 10 18 2018 30 ...

Page 31: ...Technical Manual VERSION 2 0 10 18 2018 31 ...

Page 32: ...Technical Manual VERSION 2 0 10 18 2018 32 ...

Page 33: ...Technical Manual VERSION 2 0 10 18 2018 33 ...

Page 34: ...Technical Manual VERSION 2 0 10 18 2018 34 UNIT SI mm Imperial in ...

Page 35: ...Technical Manual VERSION 2 0 10 18 2018 35 2 RC2 B outline drawings ...

Page 36: ...Technical Manual VERSION 2 0 10 18 2018 36 ...

Page 37: ...Technical Manual VERSION 2 0 10 18 2018 37 ...

Page 38: ...Technical Manual VERSION 2 0 10 18 2018 38 ...

Page 39: ...Technical Manual VERSION 2 0 10 18 2018 39 ...

Page 40: ...Technical Manual VERSION 2 0 10 18 2018 40 ...

Page 41: ...Technical Manual VERSION 2 0 10 18 2018 41 ...

Page 42: ...Technical Manual VERSION 2 0 10 18 2018 42 ...

Page 43: ...Technical Manual VERSION 2 0 10 18 2018 43 ...

Page 44: ...Technical Manual VERSION 2 0 10 18 2018 44 SI mm Imperial in UNIT ...

Page 60: ...Technical Manual VERSION 2 0 10 18 2018 60 ...

Page 83: ...Technical Manual VERSION 2 0 10 18 2018 83 NOTES ...