Technical Manual

VERSION 2.0 -10-18-2018

19

3. Lubricants

The main functions of lubrication oil in screw compressors are lubrication, internal sealing, cooling and capacity control.

Positive oil pressure in the cylinder pushes the piston together with the slide valve that is connected by a piston rod to

move forward and backward in the compression chamber. The design of positive pressure differential lubrication

system makes RC2 series normally omit an extra oil pump which is necessary for reciprocating compressors. However,

in some special applications, it is still necessary to install an extra oil pump to screw compressors for safety.

Bearings used in RC2 series compressors require a small and steady quantity of oil for lubrication. Oil injection into the

compression chamber creates a film of oil for sealing in the compression housing to increase efficiency and also can

dissipate part of compression heat. In order to separate oil from refrigerant gas, an oil separator is required to ensure

the least amount of oil carried into the system.

Please pay more attention to the oil temperature, which is crucial to compressor bearings’ life. Oil is with much lower

viscosity at high temperatures. Too low viscosity of oil will result in poor lubrication and heat dissipation in the

compressor. Viscosity is recommended to keep over 10mm

2

/s at any temperatures for oil. Oil temperature in the oil

sump should be kept above the saturated condensing temperature to prevent refrigerant migration into lubrication

system. Oil has a higher viscosity in low ambient temperature circumstances. When viscosity is too high, slow flow

speed of oil into the cylinder may result in too slow loading of the compressor. To solve this problem, use of oil heaters

can warm up oil before starting.

If the compressor operates under critical operating conditions, an extra oil cooler is required – please refer to Hanbell

selection software for the required capacity and oil flow of the extra oil cooler. Highviscosity oil is recommended to

apply in high operating conditions because high discharge temperature will make viscosity of oil lower. Oil return from

the evaporator may be insufficient in refrigeration systems, flooded chillersetc., in which it’s difficult for oil to be

carried back and it may cause oil loss in the compressor. If the system encounters the oil return problem then an extra

2

nd

oil separator is recommended to be installed between the compressor discharge tube and condenser.

Each of HANBELL RC2230 ~ RC2930 compressors is equipped with two oil sight glasses as a standard (the second

sight glass is optional for the models RC2100 ~ RC2200), one is the highlevel sight glass, and the other is the low

level sight glass (RC2230~RC2510, RC2580 and RC21020~RC21530) or internal oil line sight glass (RC2550 &

RC2620~RC2930). The function of internal oil line sight glass is to monitor lubricant flow to capacity control system

and bearings. While reverse running, it is unable to see the oil flow via sight glass. The normal oil level in the

compressor oil sump should be maintained above the top of the lowlevel sight glass and in the middle level of high

level sight glass when compressor is running. It is strongly recommended to install the oil level switch (optional

accessory) to prevent the failure results from lose of oil.

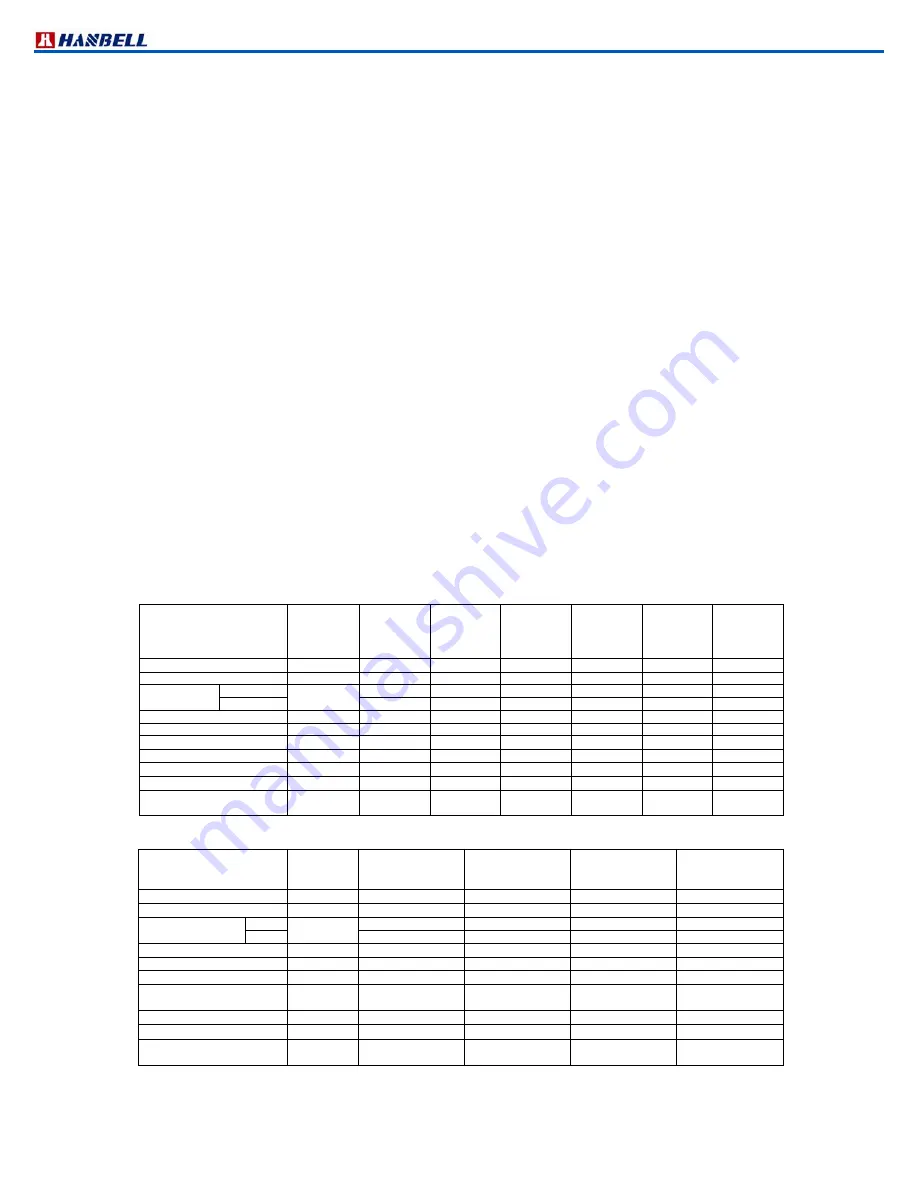

3.1 Lubricants table

Applicable oil types (R22)

SPECIFICATION

UNITS

HBR B10

HBR A02

HBR A04

HBR B09

HBR B02

HBR B01

COLOR, ASTM

1.5

L1.0

L1.0

−

−

−

SPECIFIC GRAVITY

0.883

0.914

0.925

0.95

1.01

1.05

VISCOSITY

40

℃

mm

2

/s (cSt)

56.0

54.5

96.5

175

168

298

100

℃

7.0

6.07

8.12

16.5

20.2

32.0

FLASH POINT

℃

220

188

198

265

290

271

POUR POINT

℃

40

35

25

30

43

35

T.A.N

MgKOH/g

0.01

0.00

0.01

−

−

−

COPPER STRIP

100 /3hr

℃

1a

1a

1a

−

−

−

MOISTURE

ppm

15

20

20

−

−

−

FLOC POINT

℃

75

45

35

−

−

−

DIELETRIC STRENGTH

(2.5mm)

KV

75

50

50

46.6

−

−

Applicable oil types (R134a, R404A, R407C)

SPECIFICATION

UNITS

HBR B05

HBR B08

HBR B09

HBR B04

COLOR, ASTM

−

−

−

−

SPECIFIC GRAVITY

0.945

0.94

0.95

0.95

VISCOSITY

40

℃

mm

2

/s (cSt)

64

131

175

215.9

100

℃

8.9

14.53

16.5

20.8

FLASH POINT

℃

266

254

265

271

POUR POINT

℃

43

36.5

30

25

T.A.N

mg KOH/g

−

−

−

−

COPPER STRIP

100 /3hr

℃

−

−

−

−

MOISTURE

ppm

−

−

−

−

FLOC POINT

℃

−

−

−

−

DIELETRIC STRENGTH

2.5mm

KV

−

−

46.6

−

Note:

For other applicable oil types (HFO Refrigerant), please consult HANBELL firstly for approval.

Summary of Contents for RC2 Series

Page 24: ...Technical Manual VERSION 2 0 10 18 2018 24 UNIT SI mm Imperial in UNIT SI mm Imperial in ...

Page 25: ...Technical Manual VERSION 2 0 10 18 2018 25 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 26: ...Technical Manual VERSION 2 0 10 18 2018 26 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 27: ...Technical Manual VERSION 2 0 10 18 2018 27 UNIT SI mm Imperial in ...

Page 28: ...Technical Manual VERSION 2 0 10 18 2018 28 ...

Page 29: ...Technical Manual VERSION 2 0 10 18 2018 29 UNIT SI mm Imperial in ...

Page 30: ...Technical Manual VERSION 2 0 10 18 2018 30 ...

Page 31: ...Technical Manual VERSION 2 0 10 18 2018 31 ...

Page 32: ...Technical Manual VERSION 2 0 10 18 2018 32 ...

Page 33: ...Technical Manual VERSION 2 0 10 18 2018 33 ...

Page 34: ...Technical Manual VERSION 2 0 10 18 2018 34 UNIT SI mm Imperial in ...

Page 35: ...Technical Manual VERSION 2 0 10 18 2018 35 2 RC2 B outline drawings ...

Page 36: ...Technical Manual VERSION 2 0 10 18 2018 36 ...

Page 37: ...Technical Manual VERSION 2 0 10 18 2018 37 ...

Page 38: ...Technical Manual VERSION 2 0 10 18 2018 38 ...

Page 39: ...Technical Manual VERSION 2 0 10 18 2018 39 ...

Page 40: ...Technical Manual VERSION 2 0 10 18 2018 40 ...

Page 41: ...Technical Manual VERSION 2 0 10 18 2018 41 ...

Page 42: ...Technical Manual VERSION 2 0 10 18 2018 42 ...

Page 43: ...Technical Manual VERSION 2 0 10 18 2018 43 ...

Page 44: ...Technical Manual VERSION 2 0 10 18 2018 44 SI mm Imperial in UNIT ...

Page 60: ...Technical Manual VERSION 2 0 10 18 2018 60 ...

Page 83: ...Technical Manual VERSION 2 0 10 18 2018 83 NOTES ...