Technical Manual

VERSION 2.0 -10-18-2018

47

2. Description of accessories

a. Steps or stepless capacity control system

Please refer to chapter 2.6 and 2.7 for the detail of step or stepless capacity control system.

b. Compatible steps and stepless capacity control system

For customers’ ease of stock control, possible modification of capacitycontrol logic in the future, or other special

requirements of capacity control, Hanbell deliberately designs devices for stepless/step dual capacity control as

nonstandard accessory for customers’ choices. Logic of stepless/step dual capacity control is basically identical to

those of stepless or step capacity control respectively. Please refer to Chapter 2.6, 2.7, & 2.8 for further details.

c. Suction and discharge check valve

Hanbell standard check valve (vertical type) is gravitydriven with characteristics of large flow volume and low

pressure differential. After shutdown of compressor, Teflon taper guider inside can simultaneously seal up the

precisely machined base of check valve by gravity force to effectively prevent return of highpressured gas to

compressor. The gravitydriven check valve is equipped vertically. Due to limitation of space or piping requirements,

alternative horizontal check valve is also available.

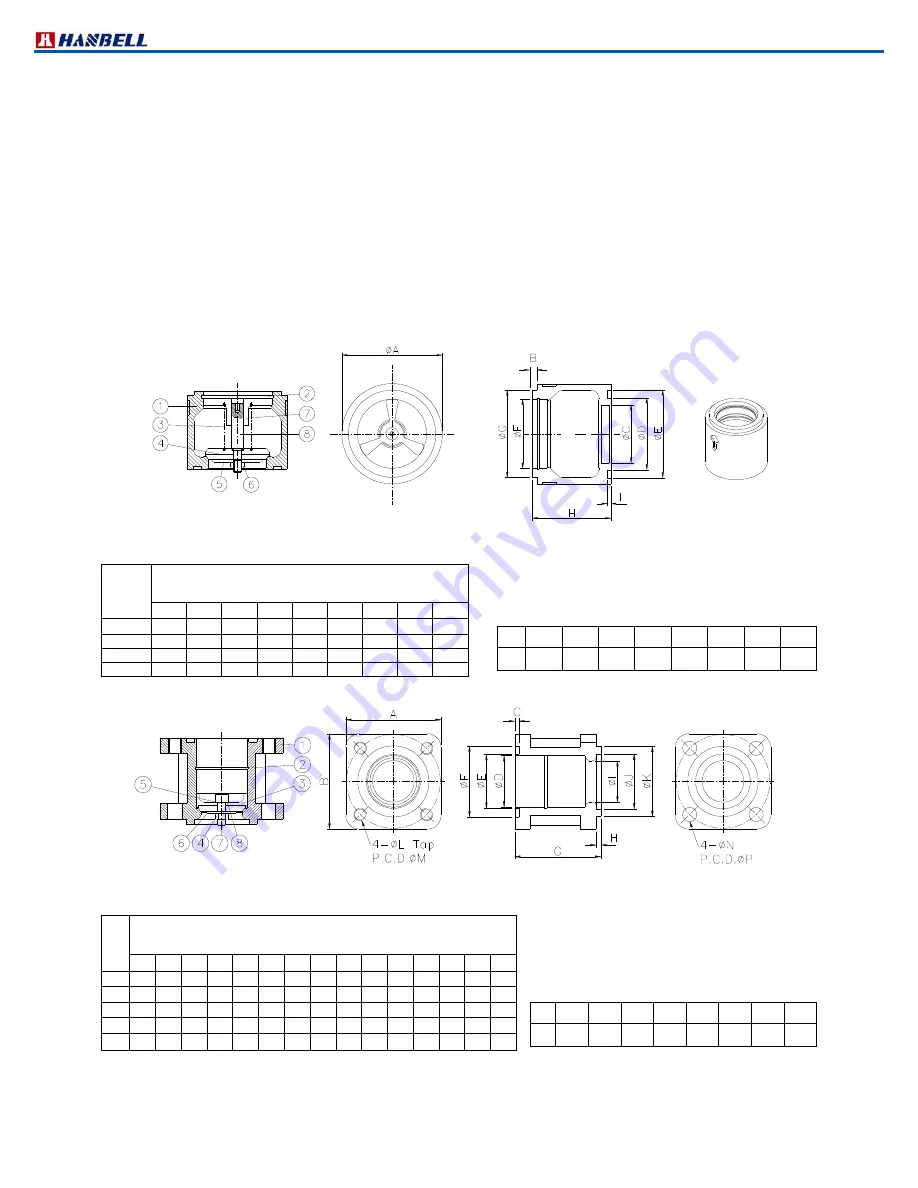

Figure 24 Suction check valve outline drawing (Horizontal type)

Dia.

Dimension unit: mm

A

B

C

D

E

F

G

H

I

2”

102

6

53

69

91

65

90

85

5

2 1/2

″″″″

122

6

69

89

111

85

110

97

5

3

″″″″

138

6

80

99

121

95

120

108

5

4

″″″″

163

6

96

124

146

120

145

123

5

Figure 25 Discharge check valve outline drawing (Vertical type)

Dia.

Dimension unit: mm

A

B

C

D

E

F

G

H

I

J

K

L

M

N

P

1 1/2

″″″″

109

109

5

55

59

76

105

6

34

60

75

M16x2 105

18

105

2”

122

122

5

65

69

91

110

6

46

70

90

M16x2 120

18

120

2 1/2

″″″″

134

134

5

85

89

111

125

6

55

90

110 M16x2 140

18

140

3

″″″″

153

153

5

95

99

121

135

6

66

100

120 M20x2

.5

160

22

160

4

″″″″

171

171

5

120

124

146

135

6

80.5

125

145 M20x2

.5

185

22

185

No.

1

2

3

4

5

6

7

8

Item

Body

C clipper Spring

Valve

plate

Gasket

Nut

Guide

seat

Shaft

No.

1

2

3

4

5

6

7

8

Item

Body

C

clipper

Guide

seat

Nut

Valve

plate

Gasket

Bolt

Washer

Summary of Contents for RC2 Series

Page 24: ...Technical Manual VERSION 2 0 10 18 2018 24 UNIT SI mm Imperial in UNIT SI mm Imperial in ...

Page 25: ...Technical Manual VERSION 2 0 10 18 2018 25 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 26: ...Technical Manual VERSION 2 0 10 18 2018 26 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 27: ...Technical Manual VERSION 2 0 10 18 2018 27 UNIT SI mm Imperial in ...

Page 28: ...Technical Manual VERSION 2 0 10 18 2018 28 ...

Page 29: ...Technical Manual VERSION 2 0 10 18 2018 29 UNIT SI mm Imperial in ...

Page 30: ...Technical Manual VERSION 2 0 10 18 2018 30 ...

Page 31: ...Technical Manual VERSION 2 0 10 18 2018 31 ...

Page 32: ...Technical Manual VERSION 2 0 10 18 2018 32 ...

Page 33: ...Technical Manual VERSION 2 0 10 18 2018 33 ...

Page 34: ...Technical Manual VERSION 2 0 10 18 2018 34 UNIT SI mm Imperial in ...

Page 35: ...Technical Manual VERSION 2 0 10 18 2018 35 2 RC2 B outline drawings ...

Page 36: ...Technical Manual VERSION 2 0 10 18 2018 36 ...

Page 37: ...Technical Manual VERSION 2 0 10 18 2018 37 ...

Page 38: ...Technical Manual VERSION 2 0 10 18 2018 38 ...

Page 39: ...Technical Manual VERSION 2 0 10 18 2018 39 ...

Page 40: ...Technical Manual VERSION 2 0 10 18 2018 40 ...

Page 41: ...Technical Manual VERSION 2 0 10 18 2018 41 ...

Page 42: ...Technical Manual VERSION 2 0 10 18 2018 42 ...

Page 43: ...Technical Manual VERSION 2 0 10 18 2018 43 ...

Page 44: ...Technical Manual VERSION 2 0 10 18 2018 44 SI mm Imperial in UNIT ...

Page 60: ...Technical Manual VERSION 2 0 10 18 2018 60 ...

Page 83: ...Technical Manual VERSION 2 0 10 18 2018 83 NOTES ...