Technical Manual

VERSION 2.0 -10-18-2018

57

E

A

B

C

D

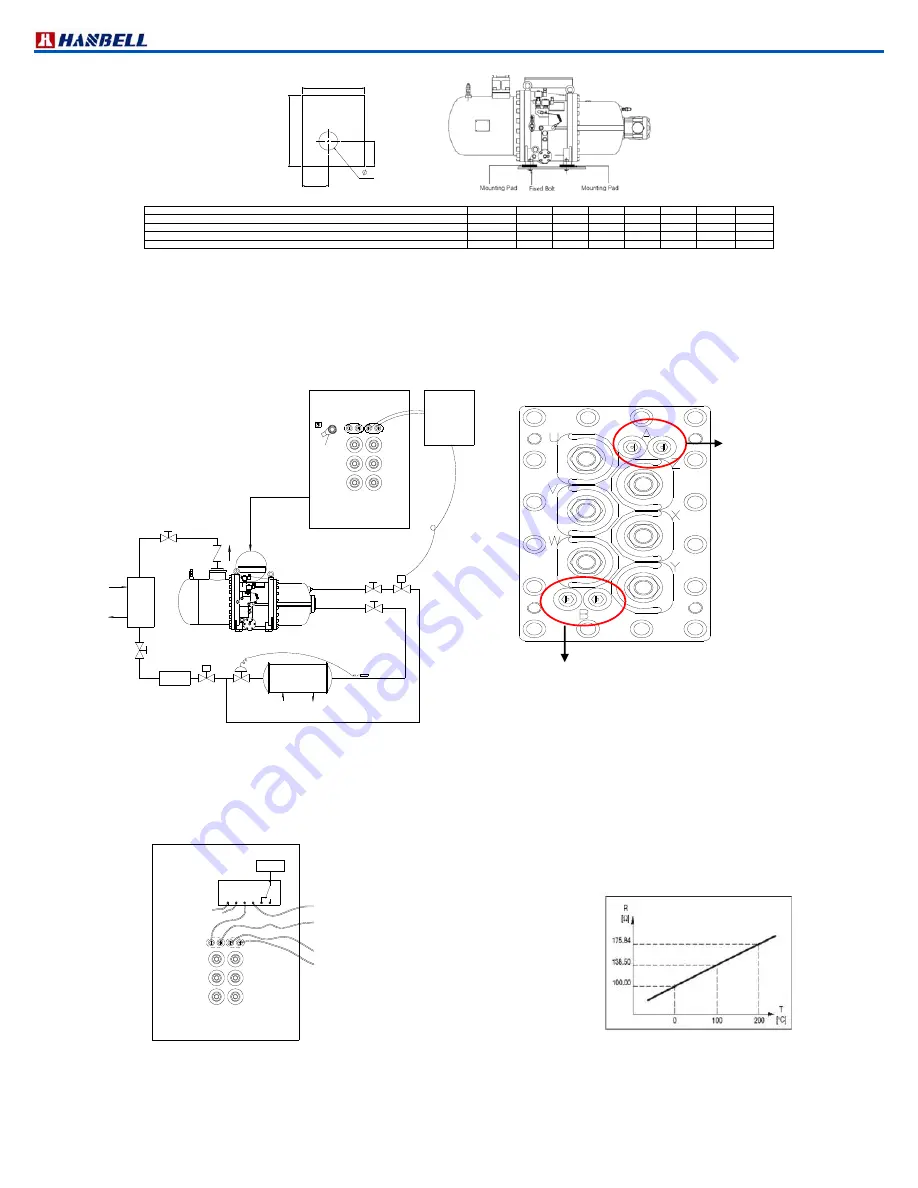

Figure 48 Compressor mounting pad (optional)

Model

Part No.

A

B

C

D

E

Thickness Req. Q’ty

RC2100, RC2140, RC2180, RC2200, RC2230, RC2260, RC2300, RC2310, RC2320

31319815B

20

55

50

20

22

20 mm

4

RC2340, RC2370, RC2410, RC2430, RC2470, RC2510, RC2550, RC2580

31369815B

26

100

70

25

22

20 mm

4

RC2620, RC2710, RC2790, RC2830, RC2930

31399815B

25

100

80

25

22

20 mm

4

RC21020, RC21130, RC21270, RC21530

31429815B

40

100

80

40

22

20 mm

4

s. Temperature sensors Pt100 or Pt1000

RC2 models utilize suction return gas to cool down the motor coil. To effectively detect temperature of motor coil

and adequately adjust volume of liquid injection by measured temperature, Hanbell specially mounts Pt100 or

Pt1000 sensor on motor coil as an optional accessory. This temperature sensor along with controller of the system

monitor motor coil temperature and then control on/off of liquid injection valve accordingly to provide suitable liquid

injection as shown in the diagram below.

s

C

ond

ens

or

s

Evaporator

Dryer

Chiller

in

Chiller

out

W

U

Earth Bolt

V

B:Pt100 / Pt1000(Optional)

A:PTC

Z

Y

X

B

A

Controller

Electric Plate

Liquid Injection S.V

Figure 49 Liquid injection connection diagram

1. Note: Hanbell suggests to control temperature of motor coil at 60

℃

(not higher than 60

℃

)

2. On the terminal cover plates, “A” is PTC sensor, and “B” is Pt1000 or Pt100 temperature sensor.

3. The terminal cover plates for models RC2710B, RC2790B, RC2830B, RC2930A, RC2930B are

shown above. The PTC sensor is on the top right side and Pt1000 or Pt100 is on the left bottom side of

terminal cover plate.

V/2

W/3

U/1

X/8

Y/9

Z/7

A

B

B Set:Pt100/Pt1000(Optional)

A Set:PTC

connect to discharge PTC sensor

connect to temperature controller for

1.controlling the liquid injection solenoid valve

2. real motor coil temperature display

3.Another motor coil protection

(for high temperature warming or tirp)

Figure 50 Connection diagram of Pt100/Pt1000 sensor

Figure 51 Pt100 sensor

A: PTC

B: Pt1000 or Pt100

Summary of Contents for RC2 Series

Page 24: ...Technical Manual VERSION 2 0 10 18 2018 24 UNIT SI mm Imperial in UNIT SI mm Imperial in ...

Page 25: ...Technical Manual VERSION 2 0 10 18 2018 25 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 26: ...Technical Manual VERSION 2 0 10 18 2018 26 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 27: ...Technical Manual VERSION 2 0 10 18 2018 27 UNIT SI mm Imperial in ...

Page 28: ...Technical Manual VERSION 2 0 10 18 2018 28 ...

Page 29: ...Technical Manual VERSION 2 0 10 18 2018 29 UNIT SI mm Imperial in ...

Page 30: ...Technical Manual VERSION 2 0 10 18 2018 30 ...

Page 31: ...Technical Manual VERSION 2 0 10 18 2018 31 ...

Page 32: ...Technical Manual VERSION 2 0 10 18 2018 32 ...

Page 33: ...Technical Manual VERSION 2 0 10 18 2018 33 ...

Page 34: ...Technical Manual VERSION 2 0 10 18 2018 34 UNIT SI mm Imperial in ...

Page 35: ...Technical Manual VERSION 2 0 10 18 2018 35 2 RC2 B outline drawings ...

Page 36: ...Technical Manual VERSION 2 0 10 18 2018 36 ...

Page 37: ...Technical Manual VERSION 2 0 10 18 2018 37 ...

Page 38: ...Technical Manual VERSION 2 0 10 18 2018 38 ...

Page 39: ...Technical Manual VERSION 2 0 10 18 2018 39 ...

Page 40: ...Technical Manual VERSION 2 0 10 18 2018 40 ...

Page 41: ...Technical Manual VERSION 2 0 10 18 2018 41 ...

Page 42: ...Technical Manual VERSION 2 0 10 18 2018 42 ...

Page 43: ...Technical Manual VERSION 2 0 10 18 2018 43 ...

Page 44: ...Technical Manual VERSION 2 0 10 18 2018 44 SI mm Imperial in UNIT ...

Page 60: ...Technical Manual VERSION 2 0 10 18 2018 60 ...

Page 83: ...Technical Manual VERSION 2 0 10 18 2018 83 NOTES ...