Technical Manual

VERSION 2.0 -10-18-2018

65

B:Pt100 / Pt1000

(Option)

A:PTC

Earth Bolt

1/U

3/W

2/V

A

B

7/Z

9/Y

8/X

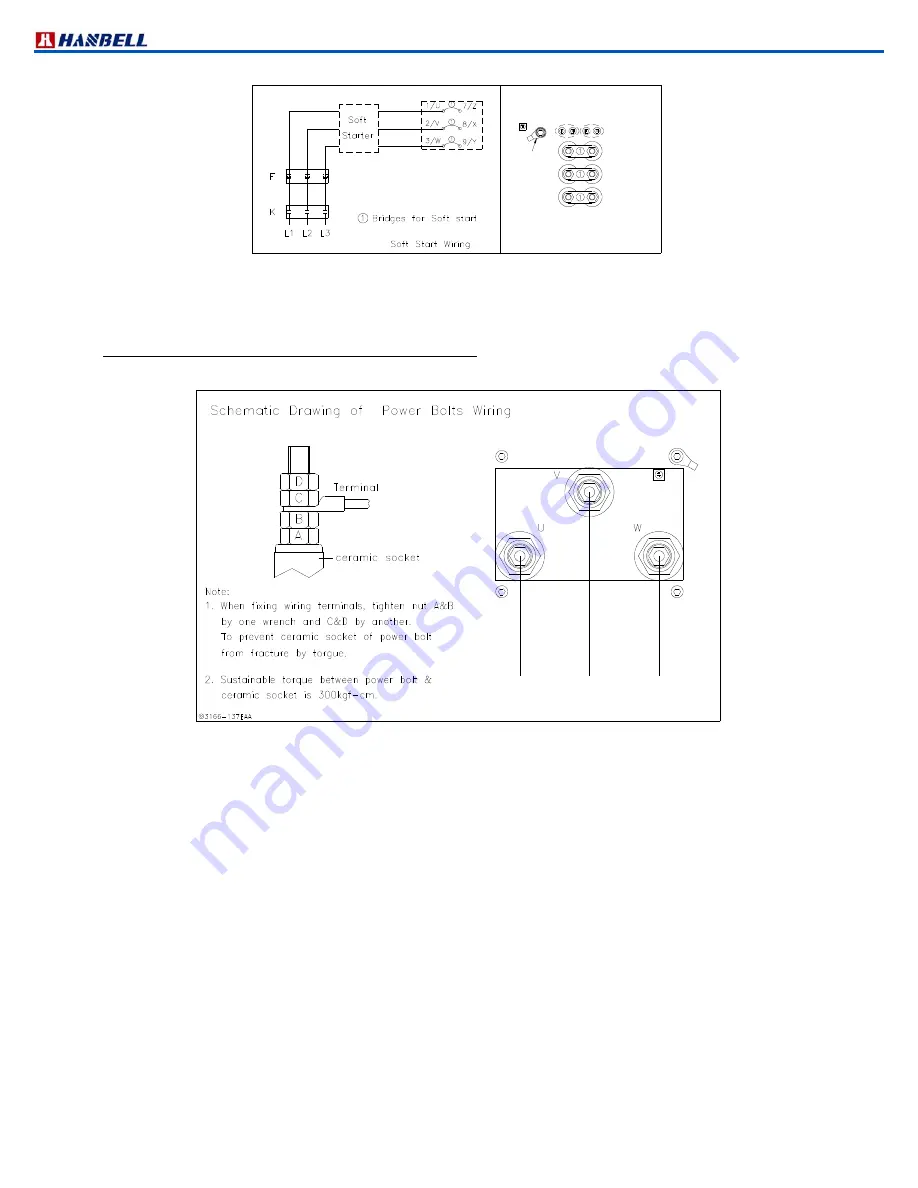

Figure 57 Soft starting diagram

Besides Y∆ and PWS start, if there were any inquiry of direct on line start

、

soft start

、

inverter start or series

reactance reduced voltage start, please contact Hanbell for further information.

Power supply wiring application (RC21270 and 1530 only)

To assure that power supply wiring to starter panel is properly installed and connected, please review and follow the

guidelines:

Figure 26: Power bolt connection

a. Power source application

(1) Verify that nameplate ratings are compatible with the power supply of the system.

(2) Use copper conductors to connect the power supply.

(3) Size the power supply wiring of the compressor: maximum current in required operating condition x 1.25

(25% safety factor).

(4) Make sure that incoming power wiring is properly phased; each power supply conduit connects to each

conductor in correct sequence to ensure equal phase representation as number 123 in order.

(5) Use flexible conduit to enhance serviceability and minimize transmission of vibration.

(6) Size the circuit breaker or fuse according to NEC or local guidelines.

(7) As install the power supply conduit, make sure that its position does not interfere with any compressor

components, or with other equipments.

b. Accessories for connection between the starter and the motor

(1) Grounding wire terminal lugs are provided inside the motor terminal box.

(2) Terminal clamps are supplied with motor terminals to accommodate standard motor wire terminal lugs.

c.

Wire terminal lugs

(1) Use adequate size wire terminal lugs for the application.

(2) Carefully choose the size of wire lugs for compatibility with the conductor sizes specified by the electrical

engineer

(3) Use copper washers on power bolt connections.

(4) Tighten each bolt to 300kgfcm

(5) These connections should be completed under supervision of a qualified engineer in compliance with NEC

or local guidelines

Summary of Contents for RC2 Series

Page 24: ...Technical Manual VERSION 2 0 10 18 2018 24 UNIT SI mm Imperial in UNIT SI mm Imperial in ...

Page 25: ...Technical Manual VERSION 2 0 10 18 2018 25 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 26: ...Technical Manual VERSION 2 0 10 18 2018 26 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 27: ...Technical Manual VERSION 2 0 10 18 2018 27 UNIT SI mm Imperial in ...

Page 28: ...Technical Manual VERSION 2 0 10 18 2018 28 ...

Page 29: ...Technical Manual VERSION 2 0 10 18 2018 29 UNIT SI mm Imperial in ...

Page 30: ...Technical Manual VERSION 2 0 10 18 2018 30 ...

Page 31: ...Technical Manual VERSION 2 0 10 18 2018 31 ...

Page 32: ...Technical Manual VERSION 2 0 10 18 2018 32 ...

Page 33: ...Technical Manual VERSION 2 0 10 18 2018 33 ...

Page 34: ...Technical Manual VERSION 2 0 10 18 2018 34 UNIT SI mm Imperial in ...

Page 35: ...Technical Manual VERSION 2 0 10 18 2018 35 2 RC2 B outline drawings ...

Page 36: ...Technical Manual VERSION 2 0 10 18 2018 36 ...

Page 37: ...Technical Manual VERSION 2 0 10 18 2018 37 ...

Page 38: ...Technical Manual VERSION 2 0 10 18 2018 38 ...

Page 39: ...Technical Manual VERSION 2 0 10 18 2018 39 ...

Page 40: ...Technical Manual VERSION 2 0 10 18 2018 40 ...

Page 41: ...Technical Manual VERSION 2 0 10 18 2018 41 ...

Page 42: ...Technical Manual VERSION 2 0 10 18 2018 42 ...

Page 43: ...Technical Manual VERSION 2 0 10 18 2018 43 ...

Page 44: ...Technical Manual VERSION 2 0 10 18 2018 44 SI mm Imperial in UNIT ...

Page 60: ...Technical Manual VERSION 2 0 10 18 2018 60 ...

Page 83: ...Technical Manual VERSION 2 0 10 18 2018 83 NOTES ...