Technical Manual

VERSION 2.0 -10-18-2018

71

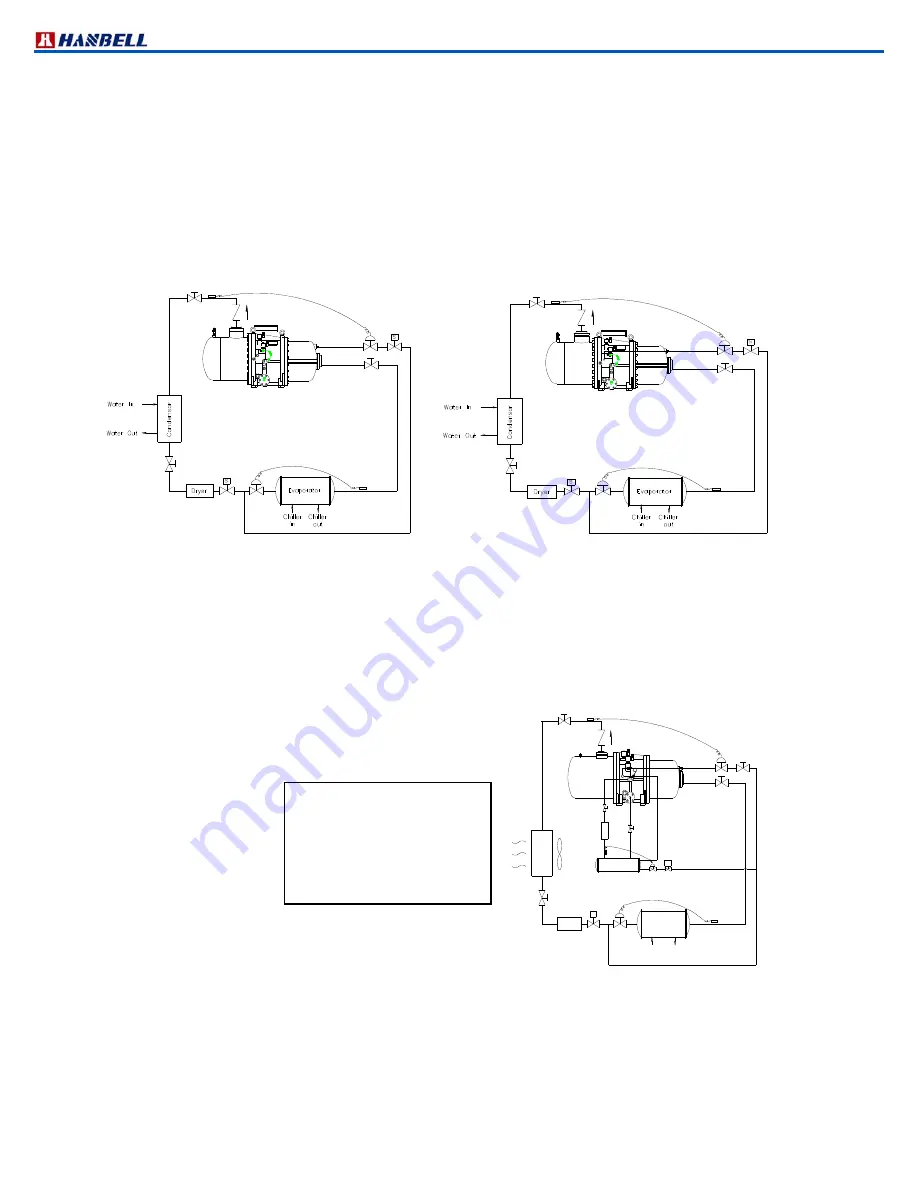

Liquid injection applied with high temperature expansion valve

Select

the high temperature expansion valve, which can sense the discharge temperature with its remote bulb. This

can control the opening of expansion valve proportionally, and can reach the best cooling effect; it will control the

compressor discharge temperature at an optimal situation of around 80

°

C.

It can also be installed with an additional solenoid valve or service valve in front of the high temperature expansion

valve for the maintenance purposes. The solenoid valve will be opened while starting the compressor. The

equilibrium tube of high temperature expansion valve should be connected to the highpressure side to counter the

internal pressure.

However, when additional cooling in compression chamber like economizer operation, oil cooler application is used,

or when condensing temperature is low, discharge temperature may be kept low and liquid injection may not be

turned on, although motor load is severe and motor coil temperature is high. This may lead to motor failure.

Therefore, in applications mentioned above, Pt100 or Pt1000 for liquid injection to motor is recommended instead.

Figure 61 Liquid injection (high temperature type) Figure 62 Liquid injection (high temperature type)

connected to motor to compression chamber

b. Oil cooler applications

Compared to liquid injection applications, external oil cooler applications reduces the discharge temperature and at the

same time gives better efficiency. Oil cooler application can be classified into 3 types: cooling by refrigerant, cooling by

ambient air, cooling by cooling water. Oil cooler capacity can be calculated manually or using HANBELL selection

software. When calculating

manually, worst case operating conditions must be considered: minimum evaporating

temperature, maximum suction gas superheat, maximum condensing temperature and the operation mode.

Cooling by refrigerant

The cooler uses refrigerant as the cooling medium. A basic

refrigerantcooled oil cooling system is shown in Figure 63.

Figure 63 Oil cooling by refrigerant

Aircooled oil cooling (cooling by ambient air)

Summary of Contents for RC2 Series

Page 24: ...Technical Manual VERSION 2 0 10 18 2018 24 UNIT SI mm Imperial in UNIT SI mm Imperial in ...

Page 25: ...Technical Manual VERSION 2 0 10 18 2018 25 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 26: ...Technical Manual VERSION 2 0 10 18 2018 26 SI mm Imperial in UNIT UNIT SI mm Imperial in ...

Page 27: ...Technical Manual VERSION 2 0 10 18 2018 27 UNIT SI mm Imperial in ...

Page 28: ...Technical Manual VERSION 2 0 10 18 2018 28 ...

Page 29: ...Technical Manual VERSION 2 0 10 18 2018 29 UNIT SI mm Imperial in ...

Page 30: ...Technical Manual VERSION 2 0 10 18 2018 30 ...

Page 31: ...Technical Manual VERSION 2 0 10 18 2018 31 ...

Page 32: ...Technical Manual VERSION 2 0 10 18 2018 32 ...

Page 33: ...Technical Manual VERSION 2 0 10 18 2018 33 ...

Page 34: ...Technical Manual VERSION 2 0 10 18 2018 34 UNIT SI mm Imperial in ...

Page 35: ...Technical Manual VERSION 2 0 10 18 2018 35 2 RC2 B outline drawings ...

Page 36: ...Technical Manual VERSION 2 0 10 18 2018 36 ...

Page 37: ...Technical Manual VERSION 2 0 10 18 2018 37 ...

Page 38: ...Technical Manual VERSION 2 0 10 18 2018 38 ...

Page 39: ...Technical Manual VERSION 2 0 10 18 2018 39 ...

Page 40: ...Technical Manual VERSION 2 0 10 18 2018 40 ...

Page 41: ...Technical Manual VERSION 2 0 10 18 2018 41 ...

Page 42: ...Technical Manual VERSION 2 0 10 18 2018 42 ...

Page 43: ...Technical Manual VERSION 2 0 10 18 2018 43 ...

Page 44: ...Technical Manual VERSION 2 0 10 18 2018 44 SI mm Imperial in UNIT ...

Page 60: ...Technical Manual VERSION 2 0 10 18 2018 60 ...

Page 83: ...Technical Manual VERSION 2 0 10 18 2018 83 NOTES ...