33

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

Chapter 3. Capacity control system

3.1 Inlet guide vanes

The cooling capacity of RT Series centrifugal compressors are modulated with change

in angles of inlet guide vanes. Before refrigerant reaches the 1

st

impeller for compression,

a pre-rotation angle has developed for changing in adiabatic head for control of its cooling

capacity.

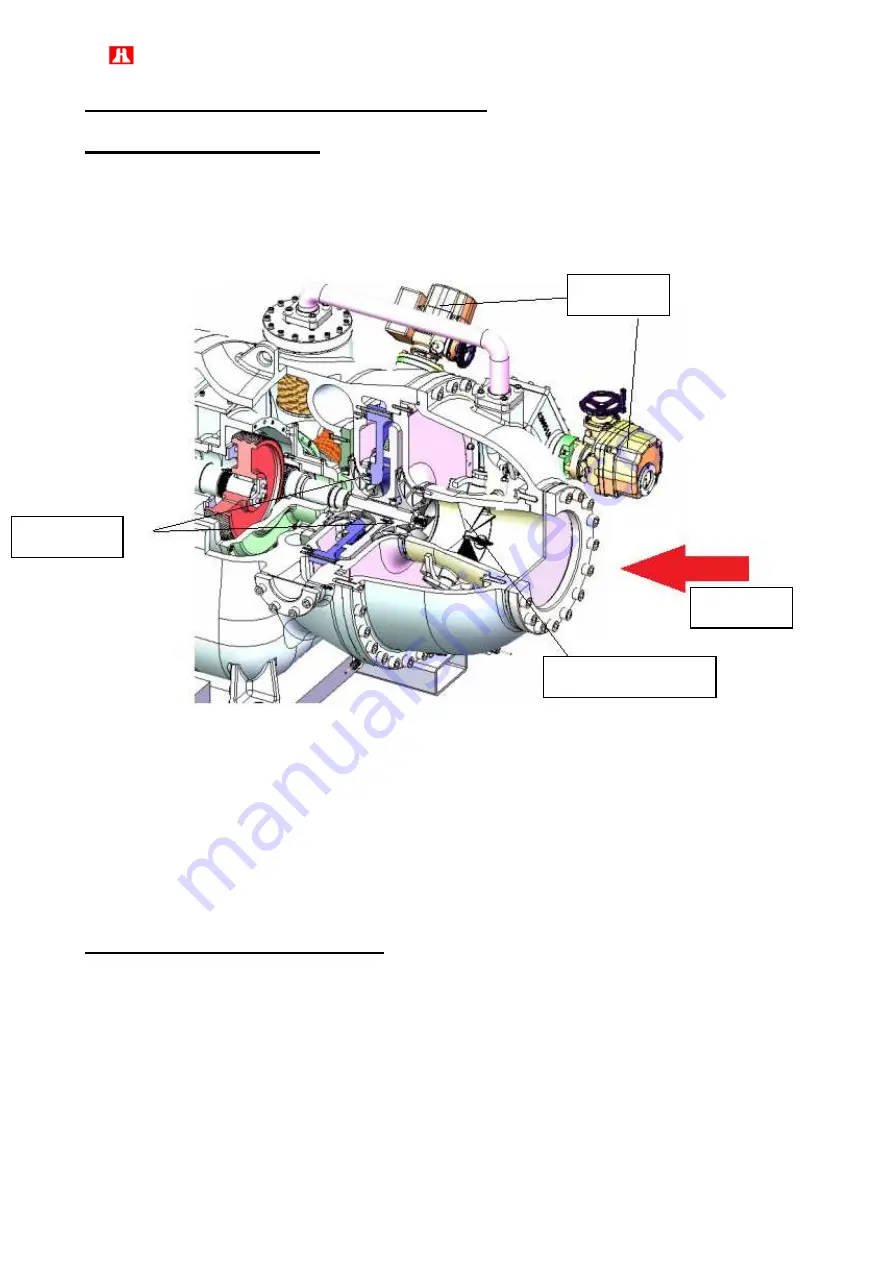

Figure 3.1 Inlet guide vanes in the compressor

Figure 3.1 Compressor inlet

As illustrated in Figure 3.1, RT series standard water-cooled compressors have first inlet

guide van (IGV1). Refrigerant gas from the evaporator outlet flows through the suction

nozzle to the compressor suction inlet. After the inlet nozzle, gas flow velocity increases

due to the narrow passage. By changing angles of IGV1, refrigerant gas enters with a

pre-rotation angle into impellers. Both gas flow speed and pressure will increase with

rotation of impellers.

Double guide vane performance

Impeller of each stage in front of IGV can only control energy change of that particular

stage. In order to get wider energy change and larger operating range, addition of IGV2

structure at the second stage is necessary. IGV2 is the variable radial guide vanes located

before the inlet of second stage impeller, which can be controlled together with IGV1 to

achieve a greater unloading capacity, equivalent to better IPLV value. Currently in Hanbell,

all standard RT-120T~200T and heat pumps include dual IGV design.

Actuator

Suction

Inlet guide vane

Impeller