43

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

3.2.7 Manual operation

To manually operate the actuator, pull the manual declutch lever towards the handwheel

until it remains in position. Turn the handwheel until the guide vanes reaches the desired

angle. Turn clockwise to close and counterclockwise to open.

Note

:

When the actuator is in power, manual mode will automatically switch to automatic

mode.

3.2.8 Overload protection

Overload protection device which detects the variation of torque during operation is

installed for preventing damage of valve and actuator under overload condition. Once the

operational torque exceeds the setting value, torque switch is tripped and actuator will be

stopped immediately.

Warning

:

:

:

:

Do not set the overload trip higher than the recommended maximum torque value.

3.2.9 Troubleshooting

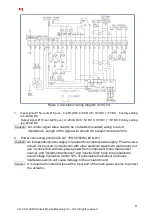

PROBLEMS

Checking Methods

Actuator does not respond

Check the power supply of actuator.

Check that the voltage matches the rating on the actuator nameplate.

Check internal wiring against actuator wiring diagram.

Check the limit switch cams.

Actuator is receiving power

but does not operate

Check the power supply of actuator.

Check actuator torque to see if it is greater than the valve torque.

Check the limit switch cams.

Check that the torque switches have not tripped.

Check mechanical travel stop adjustment.

Verify the actuator against valve rotation (standard units are

counterclockwise open).

Check internal wiring.

Check for corrosion or condensation.

Verify coupler/bracket are correctly installed and is not causing

binding.

Actuator runs erratically

Check ambient temperature.

Verify that the duty cycle has not been exceeded.

Check the position of manual operation lever.

IGV position indicator

Check resistance value.

Check whether the transmission gear is interfered.

Check board for damage.

Current / IGV position

converter

Verify input signal.

Check DIP switch configuration.

Check board for damage.

Table 3.2.9 Actuator troubleshooting

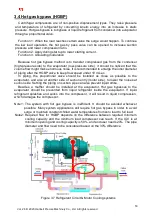

3.2.10 Actuator capacity control