49

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

m = mass flow rate of refrigerant

H = compressor head (enthalpy difference)

P = compressor input power

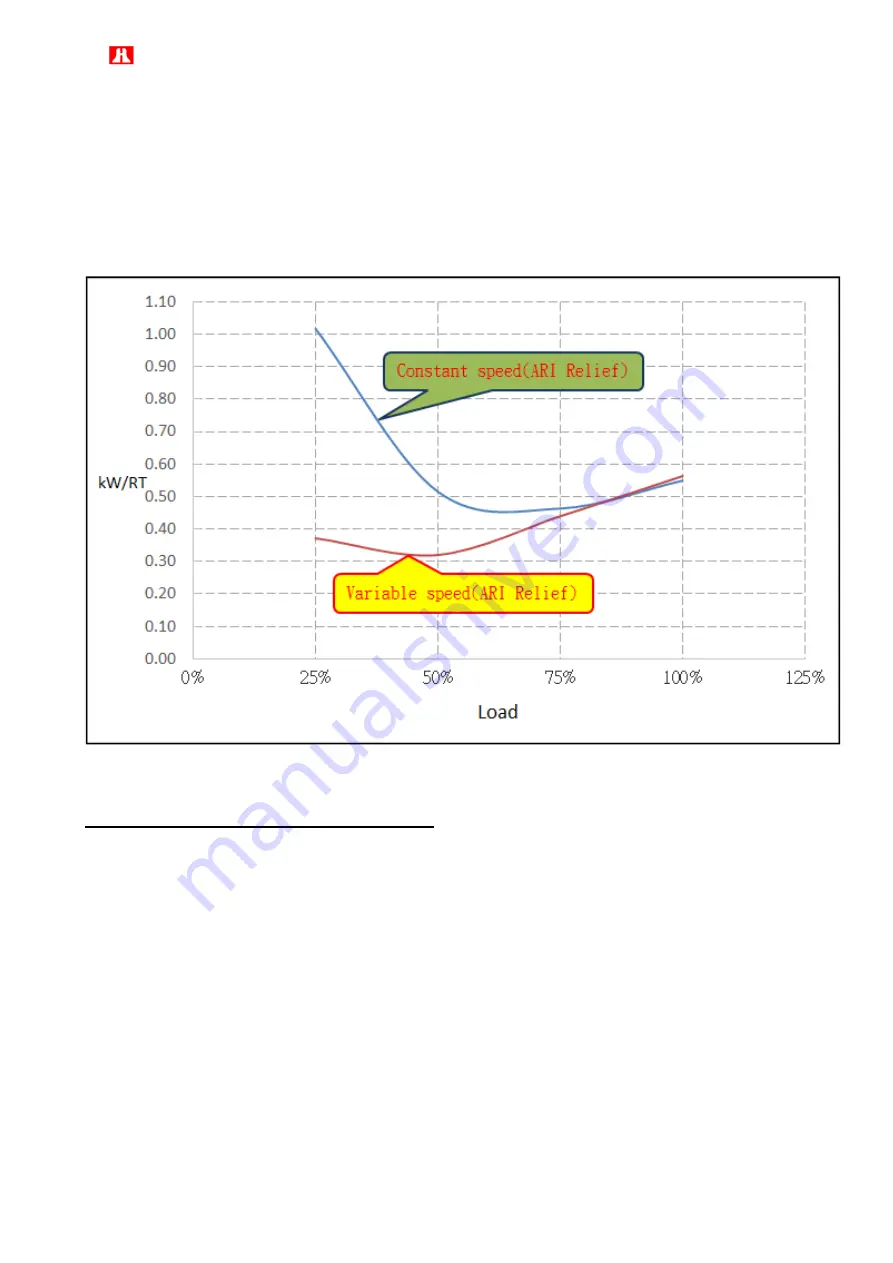

Combining compressor input power and similarity laws shows that H is proportional to the square of

the speed, m is proportional to the speed, while motor power is proportional to the cube of motor

rotational speed. Thus, by reducing the rotational speed, power input will be greatly reduced and as

a result, improving the efficiency of the compressor and reducing the power consumption of the

chiller system (Refer to Figure 3.6, for the capability of fixed/variable frequency unit and shaft power

map).

Figure 3.6 Performance map of a fixed/variable frequency unit

Chilled water temperature modulation

The VSD inverter optimizes the rotational speed of the motor and the opening of IGVs based on the

chilled water outlet temperature and the compressor head (pressure ratio), so that the unit always

operates under the best condition.

The basic parameter of VSD control is the temperature difference between the actual value of the

chilled water outlet temperature and the set value.

1.

When the unit is operating at full load, the IGVs are fully opened and the motor rotational

speed control logic is completely based on the temperature difference. As the cooling load

decreases, the motor rotational speed decreases. The motor rotational speed is controlled by

the compressor head (pressure ratio) and the system minimum allowable rotational speed,

until the rotational speed reaches the minimum value. At this point, motor will remain at

minimum speed.

2.

When the load demand reduces, motor rotational speed will provide signal for the logical

control of the IGVs so that IGV opening can be decreased. As the cooling load continues to

drop, speed signal from the compressor continues to turn off the guide vanes and increase

motor rotational speed.