53

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

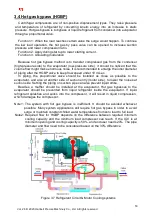

3.4 Hot gas bypass (HGBP)

Centrifugal compressors are of non-positive displacement types. They raise pressure

and temperature of refrigerant by converting kinetic energy into an increase in static

pressure. Hot gas bypass is to bypass or liquid refrigerant from condenser into evaporator

through a proportional valve.

Function 1: When the load reaches certain value the surge would happen. To continue

the low load operation, the hot gas by pass valve can be opened to increase suction

pressure and lower compression ratio.

Function 2: Apply during start up to lower starting current.

Function 3: Unloading modulation

Because hot gas bypass method is to transfer compressed gas from the condenser

(high-pressure side) to the evaporator (low-pressure side), it should be noticed that this

volume flow might make enormous noise. It is recommended to enlarge the inner diameter

of piping after the HGBP valve to keep flow speed under 10 m/sec.

In piping, the proportional valve should be installed as close as possible to the

evaporator, and also at another side of suction entry (motor side), to lower the noises at

suction side. Setting the piping on suction pipe can also prevent liquid strike.

Besides, a muffler should be installed at the evaporator. Hot gas bypasses to the

evaporator should be prevented from liquid refrigerant inside the evaporator. If liquid

refrigerant splashes and sucks into the compressor, it will result in liquid compression,

which damages the compressor.

Note1: The system with hot gas bypass is inefficient. It should be avoided whenever

possible. Many system applications still require hot gas bypass in order to avoid

surge or maintain constant chilled water temperatures from zero load to full load.

Note2: Required flow for HGBP depends on the difference between required minimum

cooling capacity and the minimum load compressor can reach. If the IGV is at

minimum opening and cooling capacity is 50%, and end user needs 20%. The pipe

diameter and flow need to be considered based on the 30% difference.

Figure 3.7 Refrigerant Circuit & Motor Cooling systems