65

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

4. If the motor has burned out, acid debris may still remain inside the system and the oil

becomes acid which will deteriorate the insulation of the motor. Therefore, it is a must to

change oil and clean the system when changing the motor. Please follow the

procedures mentioned above to change oil in the system. Check acidity of oil after 72

hours of operation and then change it again until acidity of oil becomes normal.

5. Please contact Hanbell local distributors/agents for choices of oil.

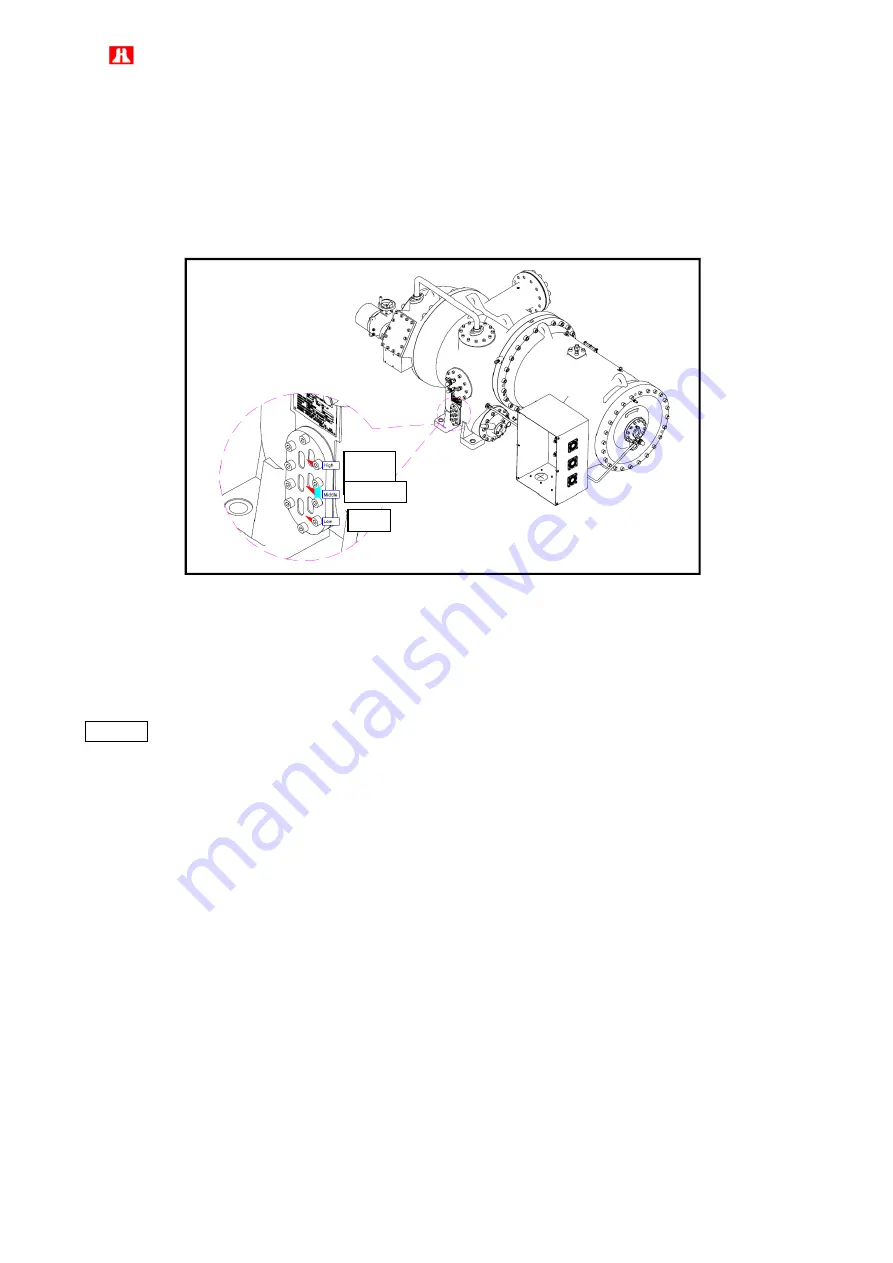

Figure 4.6Oil sight glass (Oil level)

Note: Users can refer to Figure 4.4 for charging of oil. After opening the oil separator flange,

oil can be charged at the port, item16; or oil could be charged by vacuuming the

angle valve, item13.

Warning

:

When the compressor is running, please check white floating ball inside as oil

level indicator and it’s recommended to maintain oil level between High and Middle; if the

level is higher than High, oil must be drained to keep the level below the bottom of gears; if

the level is between Middle and Low, oil return must be done or oil charge must be

replenished; else if the level is lower than Low, the compressor must be stopped

emergently to prevent dry wear of oil pump and bearing failure.

Hi

gh

Mid

L