66

Vol. 2.6 © 2020 Hanbell Precise Machinery Co., Ltd. All rights reserved

4.6.3 Oil change

Check oil periodically lubricant every 10,000-hour running. For the first operation of the

compressor, it is recommended to change oil and the external oil filter after 2,000 -hour

running. Check the system whether clean or not and then change oil every 20,000 hour or

after 3-year continuous running under good condition.

Item

Maintenance(hr)

Note

Change oil and external filter

2,000hrs

After the first operation

Check oil

10,000hrs

After continuous running

Change oil

20,000 hrs

or

3 years

After continuous running

Table 4.2 Maintenance for oil change

In order to avoid debris in the oil filter which may lead to bearing failure, the oil pressure

differential switch is recommended to be installed. The switch will sense when oil pressure

differentials between the primary and secondary sides exceeds the critical point. Then the

compressor will be shut down automatically to prevent bearings from damage due to oil

loss

Note1: Pressure gauges should be installed separately at P1 (the outlet of the oil pump)

and P2 (the outlet of the oil filter). An oil pressure differential switch should be

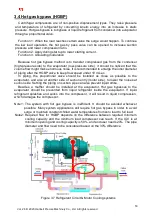

installed on piping in between for prevention of oil loss. (Please refer to the Figure

4.1 Schematic diagram of oil piping)

Note2: It is recommended replacing the external oil filter core after test of the chiller in the

factory. Otherwise, debris might clog up the external oil filter.

Note3: It is not necessary to fill additional oil when compressor working in chiller normally.

Unless there is oil carry-over or oil pumps maintenance. To fill the refrigeration oil,

the oil pump should be connected to the service valve beneath compressor oil tank.

(The amount of the oil should be ensured before restart the chiller.

Note4: Using refrigeration oil incorrectly, including using non-dedicated HANBELL oil, over

filling, inferior quality filter, improper mesh specification and improper operation

might damage the compressor. Only trained technicians are allowed to finish the

maintenance work. Any proper service requirement, please contact HANBELL

technicians.