4. If an adjustment is needed

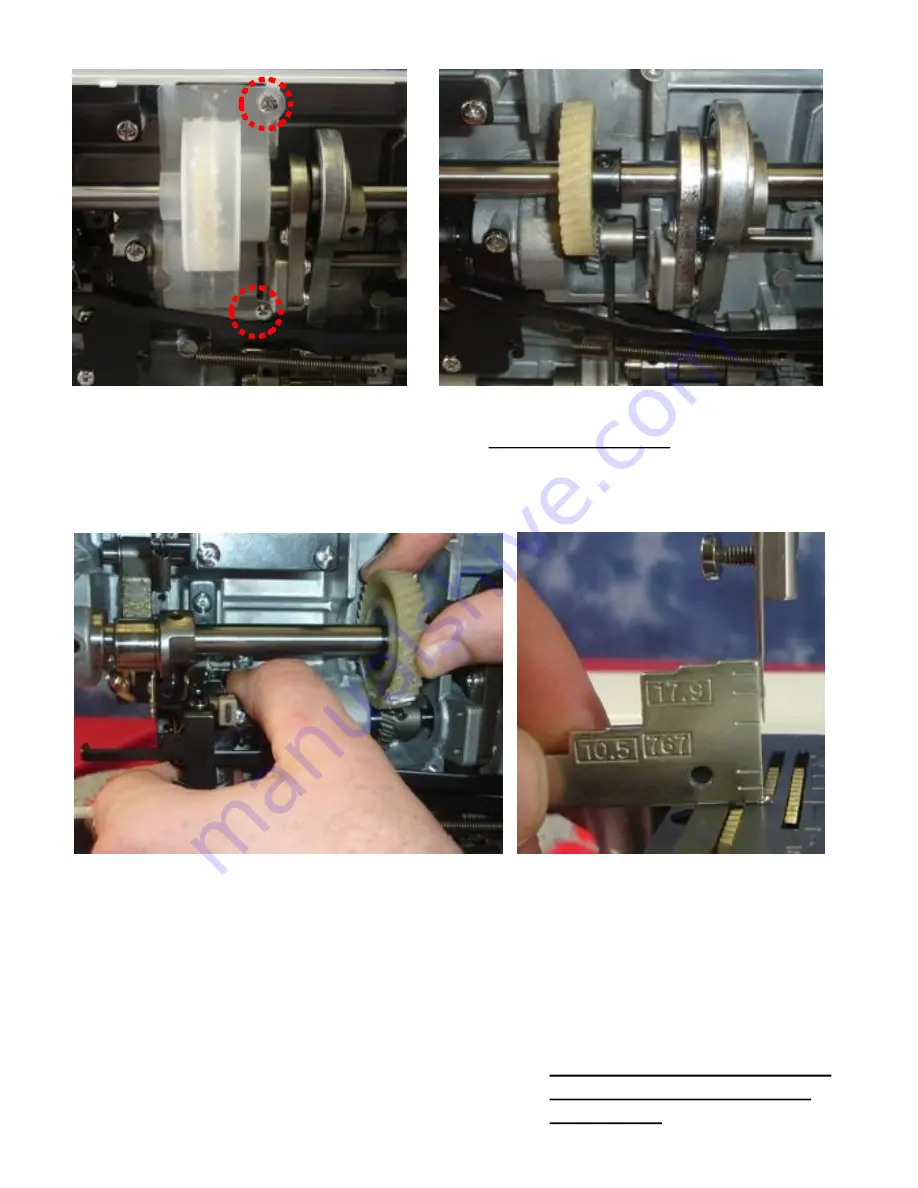

remove the two screws that hold the

hook cover plate.

5. Loosen the hex screw with a 2.5m hex

tool

on the opposite side

of the small

steel gear on the lower shaft. After

loosening the first screw, reset the

machine as in step 1, 2 and 3.

6. Loosen the second screw on the small

steel gear after resetting the thread cutter

linkage.

**The hook race has to be held

tight as soon as the second screw is

loosened on the gear.**

While holding the

hook race tight, turn the hook race gear either

clockwise to raise the needle point, or

counterclockwise to lower the needle point in

order to get the correct adjustment. Tighten a

screw on the lower shaft gear to hold the

position.

7. Reset the machine again in

order to double check with the

gauge. If correct, tighten the

other screw and put the gear

cover back on.

Important recheck and adjust

hook timing after doing this

adjustment!

45

NEEDLE TO CUTTER CAM TIMING

(2 of 2)