Automatic Thread Cutter Removal,

Adjustments, and Installation

(2 of 4)

5

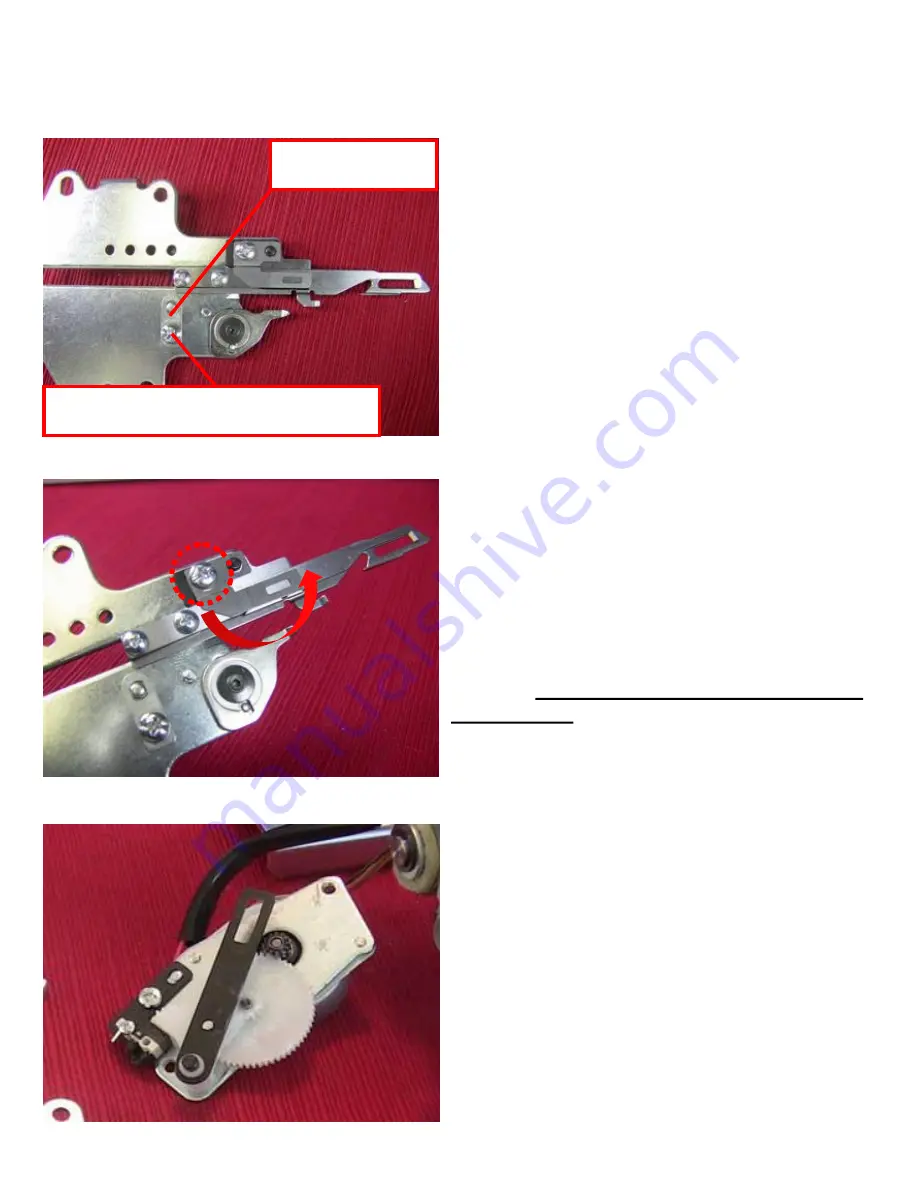

3

4.

Pull the long extending blade all the way out

and back in again, ensuring it slides smoothly.

Clean the thread cutter of lint and debris on

both the top and underside of the cutter. Put a

small drop of oil on the underside of the long

extending blade.

If the long extending blade continues to jam or

not slide smoothly, loosen the small Phillips

screw that holds the setting plate in place and

move the plate so it is as close to the long

blade as possible without it touching.

5.

If the thread cutter has trouble cutting, such

as not cutting the top or bobbin thread or the

thread is cutting too short or too long, loosen

the small Phillips screw that holds the small

cutting blade in place. If you pivot the blade

towards the back of the machine, it will cut the

thread longer. If you pivot the blade toward the

front of the machine, it will cut the thread

shorter.

Note that these are very fine

adjustments.

6.

Be sure to thoroughly clean any thread and

lint from the step motor gears. Also check for

any broken or chipped teeth on the gears. Put

a small amount of white lithium grease on the

gears to help the cutter run smoother and

quieter.

Screw for adjusting the plate

Setting plate