3. Checking and Securing Flats and Screws

The HQ Sixteen has been designed using flats and special screws so that loop lift timing cannot slip.

Tools required: (2.0 and 2.5mm handle allen)

Pitman

Pitman Crank

Check the following locations, making sure that the first

screw of a timed component has been fixed firmly on the

respective flats on shafts.

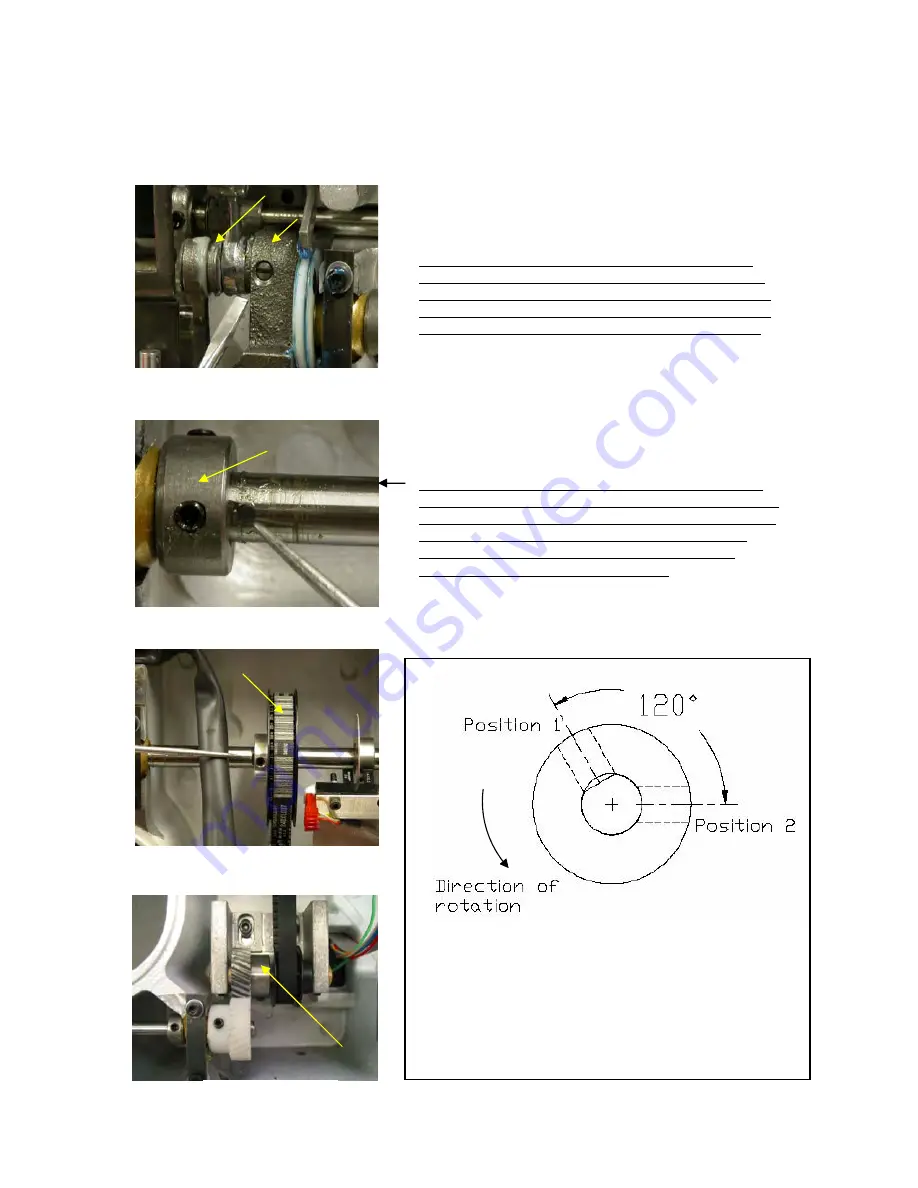

Note: The screws are generally positioned 120 degrees

apart. When the first screw (Position 1) has been located

and tightened on a flat, the second screw is then tightened,

compounding the tightness of the first screw, thus securing

and assuring that timing will not change. (see figure 3.1)

Note: See torque specifications chart in the specification

section for torque values.

Figure 3.1

Thrust Collar

NOTE: The thrust collar flat is inclined. The first screw

(shown in Figure 3.2) must be provisionally tightened. The

second screw is then fully tightened. The first screw is then

fully tightened. It is important to check that this collar

tightening procedure did not create a tight arm shaft

condition. If so, readjust the collar again.

Figure 3.2

Main Timing Pulley

FIRST SCREW, FIRST POSITION RULE

:

The first screw or first position is ALWAYS located

120° apart in the direction of rotation from the second

screw or second position.

Figure 3.3

Figure 3.4

Transmission shaft and Gear

3.0