HQ Sixteen

™

User Manual 1.6

Page 19

Troubleshooting

Stitches are Skipping

Corrective Measure

The needle is damaged, dull,

bent, or installed improperly

Incorrect needle size

The needle has not been

positioned properly

Fabric is too tight on the

frame

Thread tension too tight

Improper threading

Replace the needle often, normally once or twice per day for continuous quilting or at least once

per quilt. Use HQ Sixteen

™

recommended needles.

Always change the needle if the needle has struck any hard object such as a straight pin, etc.

The tip of the needle can become damaged or burred, resulting in fabric damage as well as

skipped stitches, thread breakage or shredding.

Always change the needle if it has been hit, bumped or pulled off center while maneuvering the

machine about the quilt. A slightly bent needle can be a major cause of skipped stitches.

Check for the proper size of needle for the work and thread being applied to the quilting

operation. Some battings and fabrics used in quilting may constrict or impede the thread passing

through the front groove of the needle. This diminishes the

loop lift required for stitch formation. Typically, a larger

needle will solve the problem; however, it has been found

that certain smaller sizes of needles as well as the use of

ball pointed needles solve some specific problems.

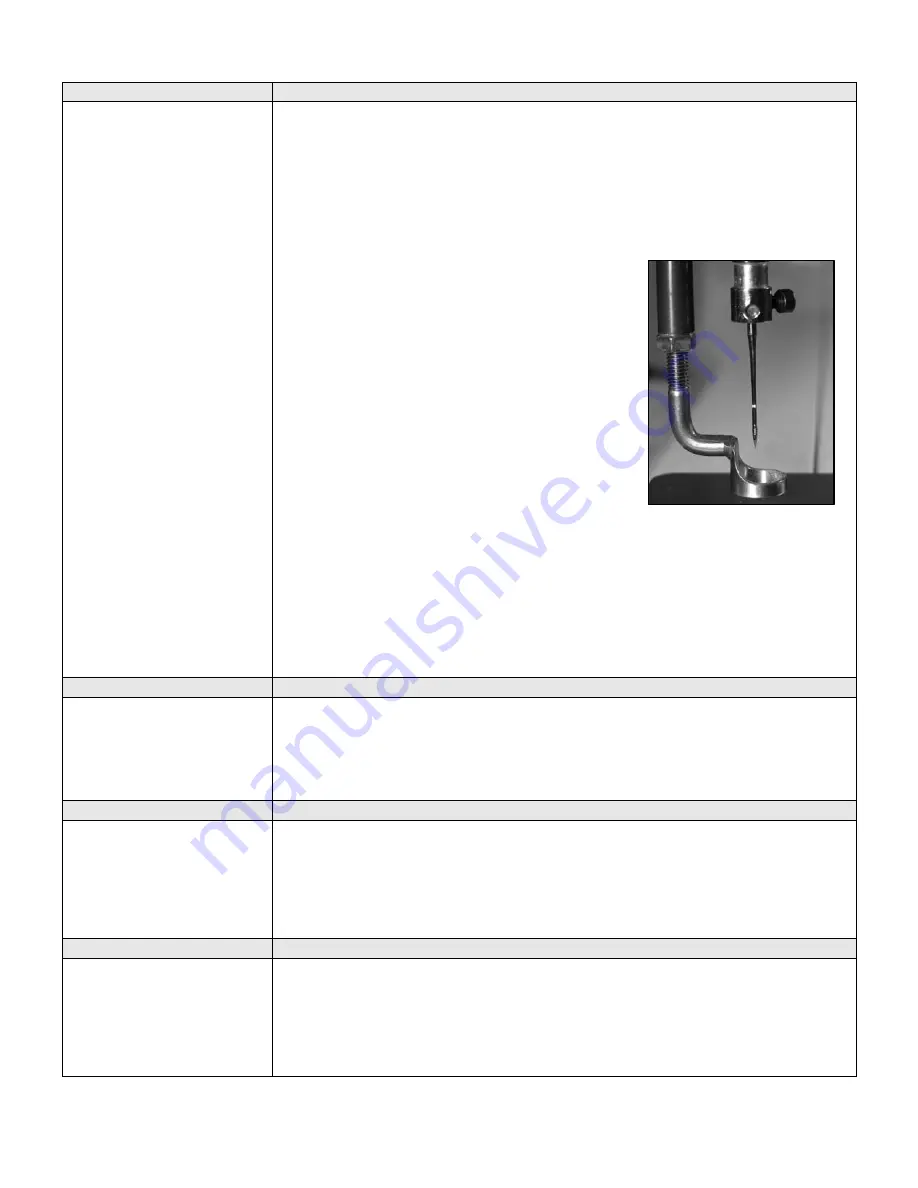

Position the needle properly to the needle bar. Inspect the

position of the needle to make sure the needle is at the 6

o’clock position (see Photo 16)—If you stand directly in

front of the needle (facing the bobbin case side of the

machine), you will see the entire needle eye directly facing

you. This is 6 o’clock position.

Make sure (1) the needle is installed all the way into the

needle bar to the needle stop hole in the needle bar, (2)

the long groove in the needle is toward the front (bobbin

case side), and (3) the scarf/scooped out part of the

needle is toward the handwheel.

The needle can sometimes be rotated to 5 o’clock (slightly

right) or 7 o’clock (slightly left) in order to adjust for a more positive thread loop pickup by the

hook point.

Loosen pole tension on the frame. Fabric that is rolled too tight causes the fibers to separate.

This reduces the needle friction on the thread resulting in a smaller thread loop.

Loosen top tension. Re-check top and bobbin tension (see pages 12-13).

Inspect that the thread take-up lever, thread stirrup or tension spring are all threaded correctly.

The Needle Breaks

Corrective Measure

The needle is bent or not

installed properly

The needle hits the throat

plate

Replace or correctly change the needle. Make sure that the needle is pushed up into the needle

bar clamp until it can go no farther (visually check that it is up to the top of the stop/sight hole

above the needle bar clamp screw). Failure to do so can cause damage in the bobbin area and

throat plate.

Correctly position the needle, throat plate or hopping foot. Replace with a new needle.

Stitches are Puckered

Corrective Measure

The hopping foot applies too

much pressure to the

material

The tension is not balanced

Needle too large for material

Decrease the pressure on the hopping foot by loosening the nut at the base of the hopping foot

shaft. Adjust to the proper height. Note: When tightening the nut on the hopping foot shaft, be

careful not to tighten so tight that it rotates the bar.

Balance the tension of the needle thread after ensuring the bobbin tension is adjusted correctly

(see page 12).

Replace the needle with a size better suited for the fabric.

Stitch Quality is Poor

Corrective Measure

The tension is not balanced

Bobbin case is damaged,

corroded, dirty, etc

Moving the machine too fast

for needle speed selected

Adjust the tension of the needle thread after ensuring the bobbin tension is adjusted correctly

(see page 12).

Since thread slides over the surface of the bobbin case at a high speed, make sure the case is

free of any lint or foreign matter that could impede thread passage through the machine.

Synchronize machine movement and needle speed to get roughly 8-10 stitches per inch.

Elongated stitches are an indication of moving the machine too fast for the current speed.

Photo 16

Summary of Contents for HQSixteen

Page 24: ...www HandiQuilter com ...