ENGLISH

UP

16

17

18

19

20

21

22

23

24

25

26

27

28

15

14

13

12

11

10

9

8

7

6

5

4

3

2

General Table

rtc-89955 TRACK DETAILS

W

S No. SG Joins Teeth TYPE

LENGTH SB No. UF RAIL TOOTH DISTANCE LENGTH

TYPE SETTING

HT

1

GROUND FLOOR

16

2

1

11

395

A

74

A

2

B-W

28 S

308

17

2

24

264

470

A

149

3

W-W

48 HR17

R159

N 18

4

4

649

B

127

4

F W-X

37 GI R596

19

5

26

286

693

C

171

5

L

X-C

44 S

484

20

6

5

55

697

C

175

B

6

C-W

10 S

110

21

7

41

708

C

186

7

W-W

54 HR54

R223

N 22

9

16

176

649

B

127

8

F W-X

13 GD R665

23

9

73

803

661

C

139

9

L

X-C

158 S

1737

24

9

129

1418

662

C

140

C

10 F

C-X

12 S

132

25

12

6

66

709

C

187

11 L X-W

13 GI R596

26

12

48

528

884

D

31

12

W-W

70 S

770

27

14

15

685

C

163

13

W-W

54 HR54

R223

N 28

15

14

154

620

B

98

14 F W-X

24 GD R665

TOTAL =

8482

15 L

X-B

15 S

165

TOTAL = 6377

DRAWING NUMBER:

CONTRACT / CUSTOMER

DRAWN:

DATE:

DO NOT SCALE

This drawing and any information or descriptive matter set out hereon are the confidential and copyright property of HANDICARE LTD.

and must not be disclosed, loaned, copied or used for manufacturing, tendering or any other purpose without their written permission.

ALL DIMENSIONS IN MM UNLESS OTHERWISE STATED

rtc-89955

mark.staniland

26/01/15

Handicare Stairlifts Ltd

REV

COMMENTS

BY

DATE

REFERENCE

R&D Position 5

PG NUMBER:

30122

BY:

Track Checked

Date:

BY:

BY:

BY:

Track Assembled

Checked M/C SHOP

MARKED FOR WELD

A

1st Issue

Hand of Rail :

Rail Colour :

DRAWING NUMBER:

Light Grey

RIGHT

rtc-89955

Track Bolts :

44

Fitting Kit

Joining plugs :

Additional Charge Points

(section/ by stanchion)

Charge Points :

Standard

End Stops :

MK2

Magnets :

6

Hand Sets :

N/A

Number needed :

0

Stanchion Feet

Standard :

7

Lower :

1

Fan :

5

Wall Brackets :

0

Heavy Duty Kit :

NO

Wire needed (m) :

8

Wood Screws for feet :

39

Stanchion bolts :

26

Located on :

16

Located on :

19,20,21

27,28

Located on :

Seat Type :

Track Only

Build parts/ track format

checked

By:

Swivel Bracket :

NO

Brace Bar :

1

UnderFloor Lower :

0

UnderFloor Standard :

0

Parts for Build

Product type:

RTC-2000

Figure 5

Figure 4

HANDICARE 2000 SIMPLICITY / STYLE INSTALLATION MANUAL

5

Track assembly

e

Follow the normal track installation procedure

from step 2 to complete the installation.

f

Once the track installation is complete cut

any excess threaded rod protruding from

the top of the foot to prevent it stopping

the lift early.

Note:

If the top communications contacts are

not connected to the hinge section the lift will

not work.

2

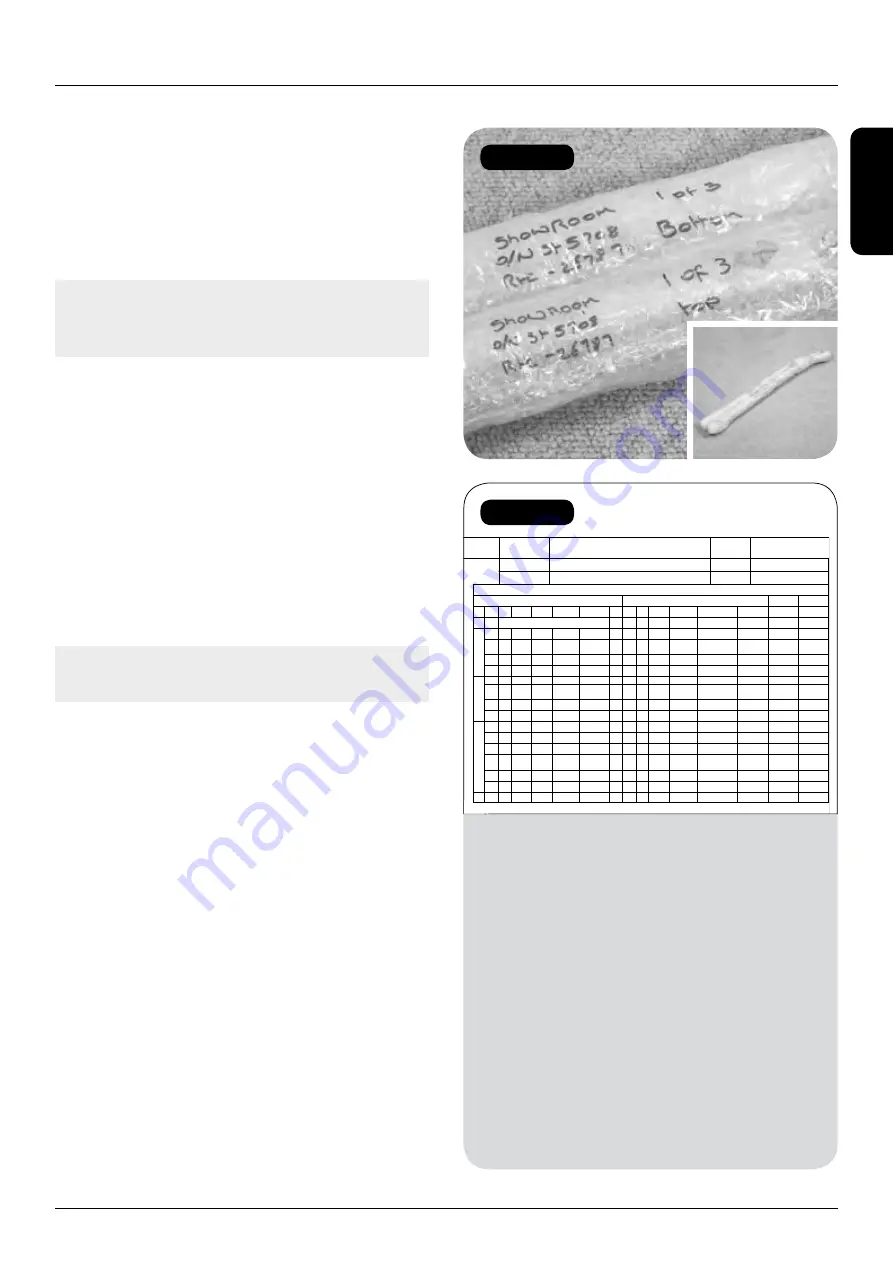

In the drawing shown in

Appendix 1

the first

section is actually a straight section with a

gradient decrease section manufactured as a

single piece of track. The straight section (2)

has 152 teeth (152 S) and it is 1671mm long.

The gradient decrease section (4) has 28 teeth

(28 GD R665) and it is bent on a 665mm

radius. The protective packaging that the track

is delivered in will be marked to indicate the

track section or sections that it contains and

whether or not it is a top track or bottom track

section

(Figure 4)

.

Note:

Do not remove the blue rack protection

cover at this stage.

Stanchion information

1

The drawing shown in

Figure 5

has a table

which shows the length of the stanchion that

has to be inserted at each position. There are

four different types of stanchion which will

be adjusted to the correct height. To ease

identification these have been labelled with

a letter, A,B,C or D.

2

Each stanchion can be adjusted to the

required height using the ‘setting height’ guide.

3

Grease the stanchion lugs as you go.

No.

– The foot number.

Rail

– The section of rail that the stanchion

fixes to.

Tooth

– The corresponding tooth on the

section of track that the stanchion should

be positioned.

Distance

– The distance of the track joint

that the stanchion is positioned.

Length

– The length of the stanchion.

Type

– The type of stanchion required.

There are four versions.

Setting height

– using the size guide

provided on each stanchion. This is the

size that the stanchion needs to be set too.