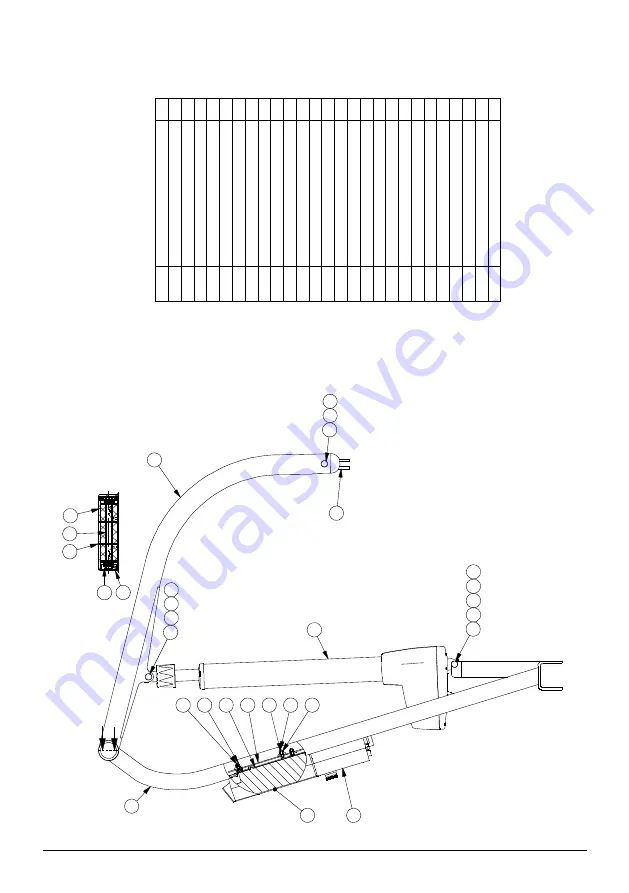

6

S E R V I C E M A N U A L

15

14

SE

C

TIO

N A-

A

17

16

18

ITE

M N

O.

TIT

LE

QT

Y.

1

Ve

g

a

liftin

g

a

rm

com

p

lete

1

2

Ve

g

a

m

a

st we

ld

ed

1

3

V

e

g

a

L

A

44

- 4

43204+

5L

3500A

0

1

4

Scr

ew

M

6S

D

IN

93

1 8

.8

M

8x

65

fz

b

1

5

N

ut cov

er

M

SM

8G

5

6

Sleev

e 1

0x

8x

50

1

7

Bu

sh

in

g

teflon

C

0B0

10

-1

01

2

1

8

Sh

ou

ld

er

b

olt I

SO

73

79

(D

IN

61

0) 1

2.9

1

0x

M

8x

35

1

9

Loc

k n

ut D

IN

98

5 M

8 fz

b

3

10

W

a

sh

er

D

IN

12

5 8

.4

x1

6x

1.6

fz

b

5

11

Sleev

e 1

0x

8x

37

1

12

Scr

ew

M

6S

D

IN

93

1 8

.8

M

8x

50

fz

b

1

13

Lin

k V

1

14

Ve

g

a

b

ush

in

g

m

a

st

2

15

Ve

g

a

liftin

g

a

rm

sh

a

ft

1

16

W

a

sh

er

n

ylon

5

0x

17

x2

2

17

Loc

k n

ut D

IN

98

5 C

L6

M

16

fz

b

2

18

Ve

g

a

en

d

cov

er

m

a

st

2

19

Loc

k n

ut D

IN

98

5 C

L6

M

5 fz

b

4

20

N

ut cov

er

M

SM

5G

4

21

Ve

g

a

con

tro

l b

ox

cov

er

C

BJ

C

1

22

Lin

a

k M

BJ

2 in

cl. scr

ew

s

1

23

Sc

re

w

M

C

6S

DI

N

7984

M

5x

16

fz

b

1

24

Sc

re

w

M

C

6S

DI

N

7984

M

5x

12

fz

b

3

25

BA

J1

03

0-0

0 (B

a

tter

y b

ox

C

BJ

g

re

y, BA

J1

)

1

26

C

BJ

04

5-0

0 (C

on

tro

lb

ox

C

BJ

C

a

re

w d

isp

la

y LA

44

)

1

22

4

8

13

1

9

2

10

3

5

5

11

21

23

20

19

20

26

9

24

6

12

25

10

7

A

A

Exploded view and components

Summary of Contents for SystemRoMedic Vega505EE

Page 23: ...23 S E R V I C E M A N U A L ...