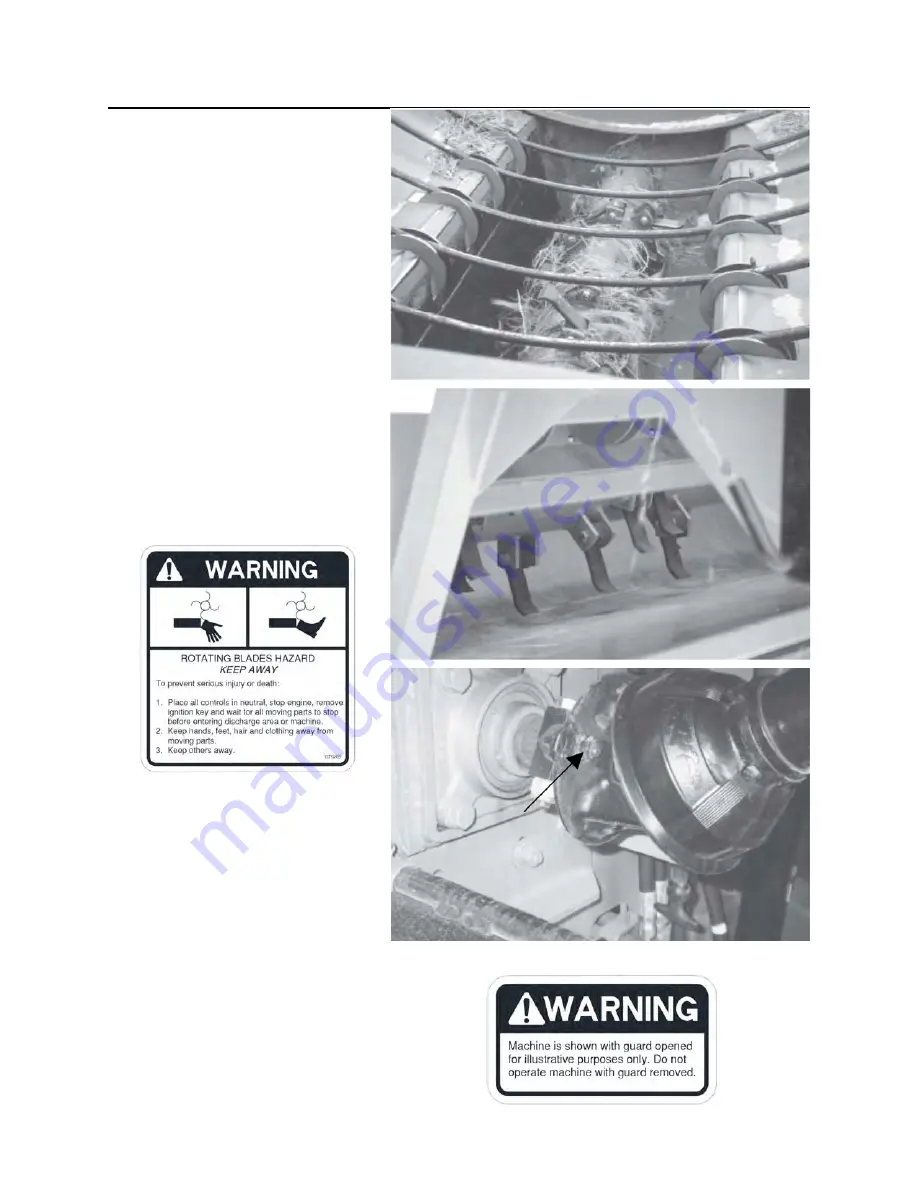

12.Rotor Cleaning:

The string or twine from the

bales does get tangled

around the rotor as the

bales are shredded. Check

every

few

bales

and

remove/clean as required.

Twine can prevent the flails

from swinging and affect

function or rotor balance.

Access the rotor through the

side access door on the side

opposite to the discharge

opening. Always stop engine

and remove ignition key

before cleaning rotor.

13.Shear Bolt:

Each input drive line is

designed with a shear bolt to

protect the machine from

shock impact loads. If the

shear bolt breaks, remove

the broken pieces and

replace with genuine H&S

replacement parts. Remove

all

material

from

the

processor before restarting

the machine.

- 4.13 -

L

R

NOV 2016

VK

Summary of Contents for 2958

Page 4: ...1 3...

Page 5: ...1 4...

Page 6: ...PAGE INTENTIONALLY LEFT BLANK 1 5...

Page 44: ......

Page 52: ...7 2 OVERALL DIMENSIONS 7 2 L R NOV 2016 VK...

Page 53: ...7 3 BOLT TORQUE 38 7 3 L R NOV 2016 VK...

Page 54: ...PAGE INTENTIONALLY LEFT BLANK...

Page 56: ...8 1 Frame Assembly 8 2 8 2 L R NOV 2016 VK...

Page 60: ...PAGE INTENTIONALLY LEFT BLANK...

Page 62: ...8 5 Drive Rotor Assembly 8 7 L R NOV 2016 VK...

Page 64: ...8 6 Deflector Assembly 8 9 L R NOV 2016 VK...

Page 68: ...8 9 Load Frame Assembly 8 13 L R NOV 2016 VK...

Page 70: ...8 10 Cradle Hydraulics 8 15 L R NOV 2016 VK...

Page 73: ...N 9 1...

Page 74: ...N 9 2...

Page 75: ......

Page 76: ......