-21-

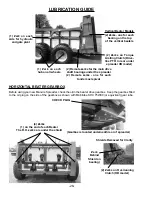

PREPARING FOR OPERATION

Before operation, run machine slowly to make sure that the spreader is operating and lubricated properly.

PTO ASSEMBLY

Attach the PTO of the spreader to the tractor by sliding the spring loaded locking collar on PTO yoke

rearward, then sliding it onto the tractor PTO shaft. Release spring loaded collar. Be sure the pins fall into

the groove of the tractor PTO shaft and collar snaps forward into locking position.

CAUTION:

Do not use a steel hammer to aid in joining PTO parts.

Keep the male and female driving elements well lubricated and free sliding. Failure to observe this

precaution will result in excessive pressure being required to collapse or extend the assembly while

subject to operating torque. This excessive force may damage or displace the main shaft bearings. DO

NOT lubricate the shield surfaces. The shield surfaces must be kept dry, as dirt accumulation on them will

quickly cause these units to bind and not rotate. Be sure that the rotating integral shields are not dented or

damaged, as this also will result in excessive force being applied against the jackshaft. Damaged shields

also cause obvious difficulties when installing the assembly. If at any time the shields do not turn freely,

they should be checked to determine the cause, and repaired or cleaned. To avoid damage to the main

drive bearings, avoid turning sharp corners while PTO is running. Start and Stop PTO slowly to avoid

damage to the drive line.

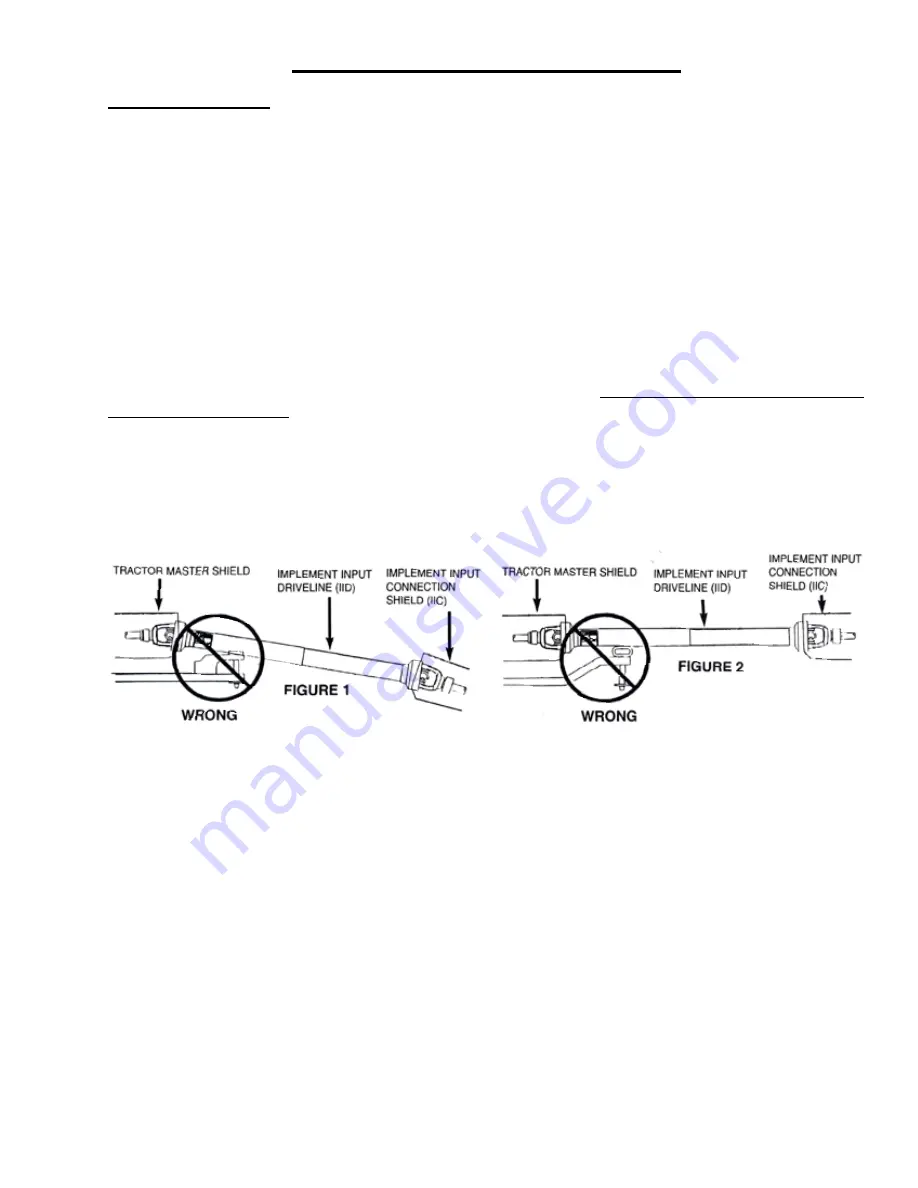

If this implement is attached to a tractor with an

offset in the drawbar, be certain it is in the down

position to prevent damage to the IID guarding

and the IID telescoping members. [See Figure 2]

If this implement is attached to a tractor with a clevis

hitch (hammer-strap) style drawbar, the ham

-

mer-strap must be removed to prevent damage

to the IID guarding and the IID telescoping members.

[See Figure 1]

Summary of Contents for 4242

Page 6: ...4 Intentionally Left Blank...

Page 8: ...6 Intentionally Left Blank...

Page 10: ...8 Intentionally Left Blank...

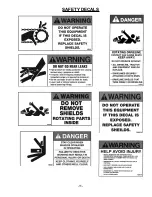

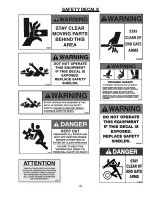

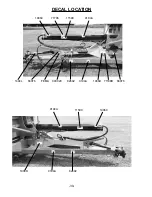

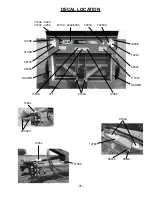

Page 13: ...11 SAFETY DECALS...

Page 14: ...12 SAFETY DECALS...

Page 15: ...13 SAFETY DECALS...

Page 18: ...16 HYDRAULIC FITTING TORQUE SPECIFICATIONS...

Page 19: ...17 HYDRAULIC FITTING TORQUE SPECIFICATIONS...

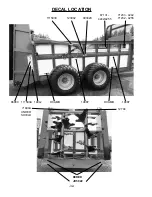

Page 38: ...36 DECAL LOCATION 425 Bushel DCRED 093020 093020 111593A 1494J 86060 DCAMB...

Page 41: ......