-30-

TIRES & WHEELS

Check the tire pressure after every 10 hours of operation. Tires should be inflated to the appropriate

pressure listed in the table.

Tire

Pressure

21.5L x 16.1 – 18 Ply

44

445/65R22.5

85

49x19x20

80

700/50x22.5

41

Wheel lug torque should be checked after every 50 hours of operation and tightened to the appropriate

torque.

Wheel bolts must be tightened between 375-425 ft/lbs of torque.

SERVICE

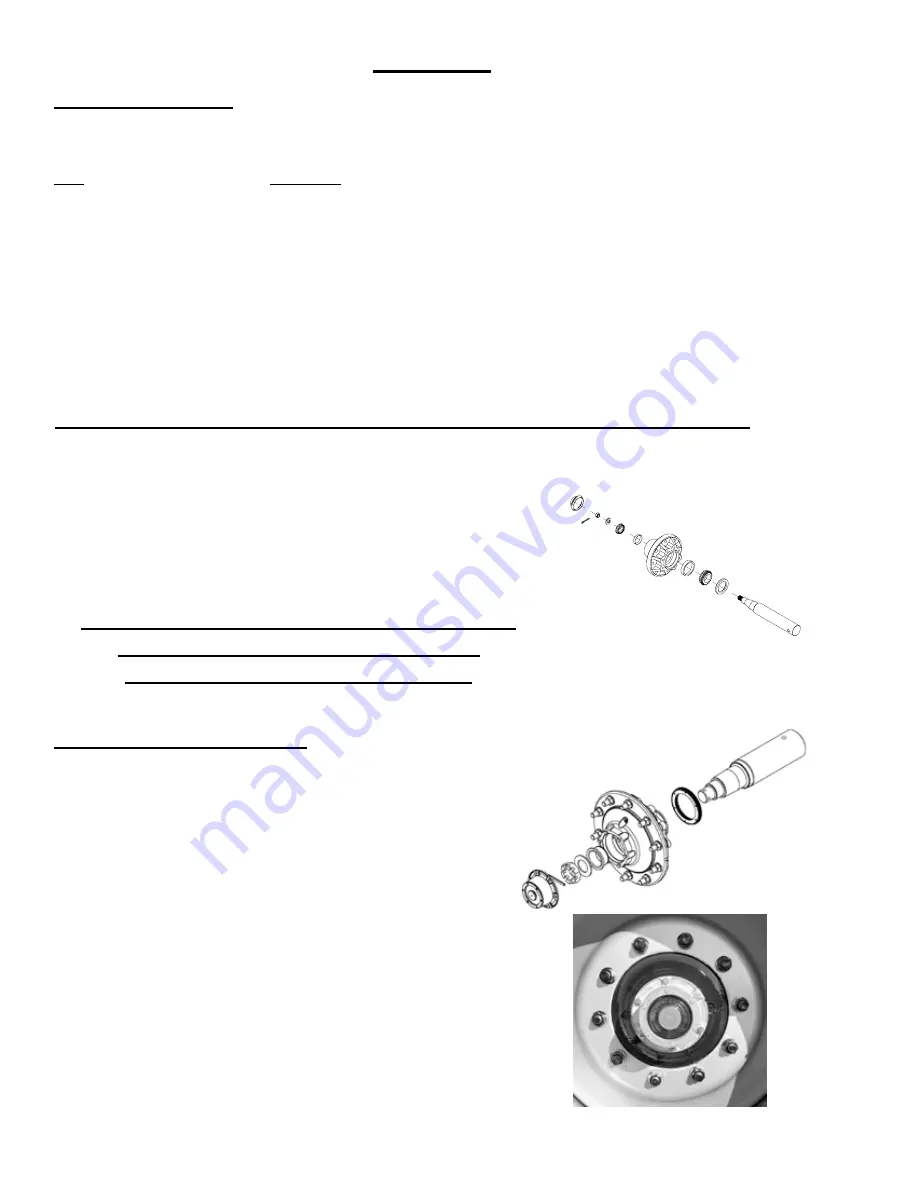

WHEEL BEARING LUBRICATION, CLEAN & RE-PACK INSTRUCTIONS

Grease wheel bearings as needed depending on amount of travel.

Annually disassemble and clean parts in a solvent. Pack bearings

with a high grade grease. Reassemble, and tighten nut until a slight

drag is felt when wheel is turned. Back nut off and insert cotter pin

into first hole that you see as you back the nut off, bend cotter pin

over and reinstall cap.

WHEEL HUB - OIL BATH

OIL ASSEMBLY - DO NOT GREASE!

Follow the steps below when installing a new seal or

adjusting the hub tighteness.

1.

Wipe the rubber seal with oil before installing.

2.

Assemble as shown in the picture.

3.

Torque the spindle nut to 110 ft. lbs. while rotating the

hub to seat in the bearing assembly.

4.

Loosen the spindle nut and re-torque to 70 ft. lbs. while

rotating the hub.

5.

Loosen the spindle nut to no more than 30 degrees to

install the spring pin.

6.

With the hub horizontal, remove the plastic cap and fill

the hub cavity to the fill line with Casrtol Hyspin VG46

hydraulic oil. Replace the plastic cap.

FOLLOW THE INSTRUCTIONS ABOVE

FOR GREASEABLE HUBS, AND

BELOW FOR OIL BATH HUBS!

Summary of Contents for 5234

Page 6: ...4 Intentionally Left Blank...

Page 8: ...6 Intentionally Left Blank...

Page 10: ...8 Intentionally Left Blank...

Page 13: ...11 SAFETY INFORMATION...

Page 14: ...12 SAFETY INFORMATION...

Page 17: ...15 HYDRAULIC FITTING TORQUE SPECIFICATIONS...

Page 18: ...16 HYDRAULIC FITTING TORQUE SPECIFICATIONS...

Page 43: ...41 SERVICE NOTES...

Page 44: ...42 SERVICE NOTES...

Page 45: ......