-13-

HYDRAULICS

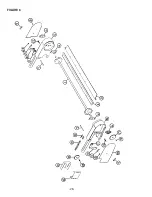

There are four hydraulic hoses from the merger to the tractor. The two smaller, (3/8’’ diameter) hoses pro-

vide oil to the pickup lift cylinder (A).

The two larger (1/2’’ diameter) hoses provide oil to the hydraulic motors (B) running pickup belt and cross

conveyor belt. Controlling speed of belts is done by adjusting oil flow at the tractor remote (if possible) or

by adjusting the tractor throttle. Coordinate speed of belts with ground speed of tractor. To reverse direc-

tion of cross conveyor change hydraulic quick couplers at the cross conveyor drive motor (C). A flow of 16

GPM and pressure of 2,000 PSI is recommended to operate the merger efficiently.

DO NOT GO NEAR LEAKS

• High pressure oil easily punctures skin causing

serious injury, gangrene or death.

• If injured, seek emergency medical help.

Immediate surgery is required to remove oil.

• Do not use finger or skin to check for leaks.

• Lower load or relieve hydraulic pressure

before loosening fittings.

11599

B

A

C

Summary of Contents for M6

Page 4: ......

Page 15: ...15 LUBRICATION Continued B I Under Shield E G A C D F H A I Under Shield...

Page 19: ...DECAL LOCATION Continued A B L I K C Behind Shield Behind Shield A B 19 J D K I L C E G F...

Page 20: ...20 FIGURE 1...

Page 22: ...22 FIGURE 2...

Page 24: ...24 FIGURE 3...

Page 28: ...28 FIGURE 6...

Page 32: ...SERVICE NOTES 32...

Page 34: ...H S MFG CO products approved for the FEMA SEAL OF QUALITY...