7

A

B

C

Actual Floor Size

Building Size

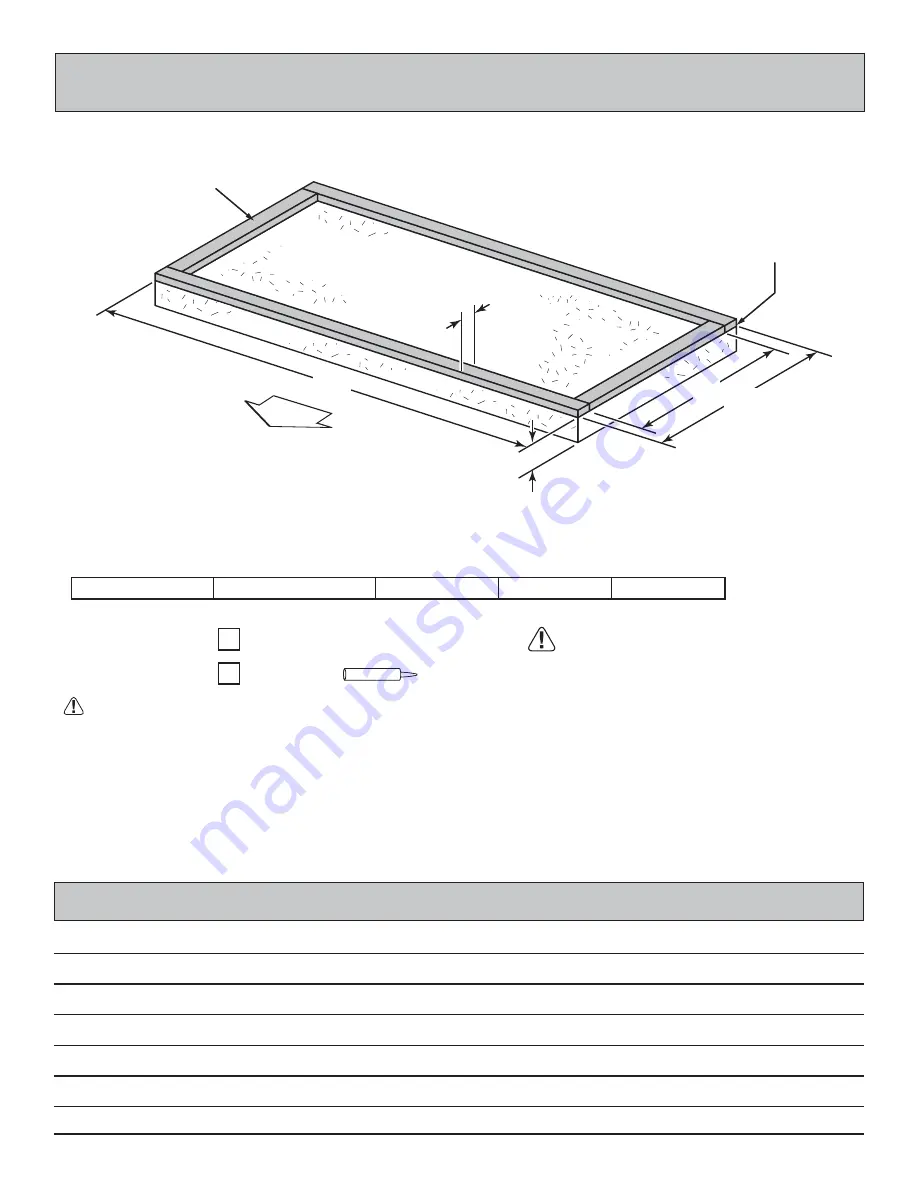

• A treated 2 x 4" (5,1 x 10,2 cm) sill plate is required when installing your shed on concrete.

Hint: Use treated lumber in your kit (you will have to cut to fit).

• Use a high quality exterior grade caulk beneath all sill plates.

• Fasten 2 x 4" (5 ,1x 10.2 cm) sill plates to slab using approved concrete anchors

(fasteners not included)

.

• Check local code for concrete foundation requirements.

68-1/4" (173,4 cm)

36" (91,4 cm)

6'x 3' (182,9 x 91,4 cm)

29" (73,7 cm)

NOTES

Treated Sill Plate

Caulk between sill plate

and concrete.

2 x 4 x 8' (5,1 x 10,2 x 243,8 cm)

Requires:

x3

MUST be treated lumber.

Caulk

x1

Allow new concrete slabs to cure for at least seven (7) days.

3-1/2"

(8,9 cm)

4"

(10,2 cm)

A

B

C

CONCRETE FOUNDATION

If you choose to install your kit on a concrete slab refer to the diagram below.

68-1/4"x 36" (173,4 x 91,4 cm)

DOOR