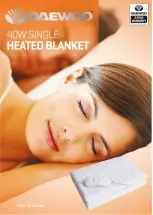

Carbon Film

Installation Instructions

Page 7

Sensor Tip

50mm Gap

Depron

Cold Tails

Cold Tai

ls

Step 11

Fig. 12

Position the floor sensor.

If installing

Heat-Pak® over the carbon system, refer to separate instructions regarding the floor

sensor.

For standard installation, the tip of the sensor sh

ould be approximately 300-500mm from the edge of the room with the tail

of the probe running back to the thermostat via the 50mm cold tail gap. Fig. 12. Form a channel in the foam underlay, in

between two of the elements running into the cold tail gap. Press the sensor into the channel and tape in place with self

adhesive cloth tape.

The sensor wire can be shortened or if required lengthened up to 50m with a minimum 0.75mm² 2-core flex cable. This

connection should be located above floor level ideally within the cold tail junction box.

It is advisable to mark on the installed location of the sensor tip, on the floor plan for future reference.

Test the resistance of the floor probe. Refer to the label on the floor probe wrapper for desired resistance readings. Make

a note of the reading.

When you are satisfied with the layout, cover the heating elements with the plastic sheet/moisture barrier provided

. The

grade of PE-Sheet supplied will depend upon what is being installed over the system. If a wood floor, engineered wood or

laminate floor is being laid, a 100micron sheet (clear) will be provided. When fitting Heat-Pak® over a carbon heating sys-

tem a 200micron sheet (coloured blue) has to be used. The joints of the sheeting have to overlap by at least 20 cm. These

overlaps have to be sealed over their total length with a self-adhesive PVC cloth tape (Duct Tape)

Step 12

The floor finish can now be laid directly over the moisture barrier in accordance with the flooring manufacturers instruc-

tions.

Under no circumstances

should a separate underlay be installed at any point between the heating element and

the floor finish. Ensure that the floor finish has been acclimatised prior to installation to avoid excessive shrinkage when

heated. Refer to the notes on page 2 of this manual.

During the process of laying the floor, care should be taken not to damage any of the heating elements or cold tails. A

spare sheet of foam underlay or a board, can be used to kneel on to help spread weight.

Step 13

Once the floor finish has been laid, perform resistance tests on the floor probe and across the feed cable that connects the

thermostat to the junction box, to ensure that no elements have been damaged during the flooring installation. The desired

resistance reading for the heating system is at the bottom of the room test data sheet and should be within the tolerance of

+

10 –5%. Record the final readings on the guarantee certificate.

Once this test has been completed, final connections to the thermostat can be made. See Separate installation instruc-

tions for the thermostat.

Step 14