16

Section 5: Mounting the Wing to the Fuselage

Complete wing assembly

Fuselage

Wing dowel rods (2)

Fuselage wing hold-down screws/washers (2)

Blind nuts (2 )

Wing center plate

Wing bolt plate

CA glue (thin)

Drill

Drill Bit: 1/8", 1/4"

Phillips screwdriver (medium)

Round file (small)

Hobby knife

6-minute epoxy

Measuring device (e.g., 36" ruler or tape measure)

Masking tape

Rubbing alcohol

Paper towels

Felt-tipped pen or pencil

Parts Needed

Tools and Adhesives Needed

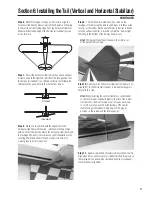

Step 1.

Locate the two dowels, nylon wing bolts, blind nuts,

wing bolt plate, and the tapered wing center plate section that fits

between the wing and front windshield former in the fuselage.

Step 2.

Locate the shaped leading edge piece (wing center

plate) that goes in the wing and fits into the opening of the front

windshield former. Trial fit the wing to the fuselage to see if any

material needs to be removed from the tapered block so that the

wing will fit snugly onto the fuselage. Mix approximately 1/4 oz

of 6-minute epoxy and glue the shaped leading edge piece into

the slot in the wing as shown. Allow the epoxy to cure before

attempting to drill holes for the wing hold down dowels.

Step 3.

Locate the two holes in the leading edge of the fuselage

front windscreen former. The holes have been predrilled in the

plywood former. Trial fit the dowels to make sure they will slide

into the holes without binding. When you’re satisfied, remove

the dowels.

Step 4.

Use a ruler to mark the center line of the fuselage

opening where the trailing edge of the wing will rest on the

fuselage. We will use this mark to help center the wing on the

fuselage prior to drilling the wind bolt holes.

Summary of Contents for Clipped-wing Taylorcraft

Page 55: ...55 Notes ...