32

Section 11: Installing the Engine (Glow)

Fuselage

Metal engine mounts (2)

Mounting hardware

Engine

Phillips screwdriver

Allen wrench

30-minute epoxy

Epoxy brush

Rubbing alcohol

Paper towels

Parts Needed

Tools and Adhesives Needed

Note:

When any engine is properly mounted the distance

from the engine firewall to the back of the engine drive

washer should be 6".

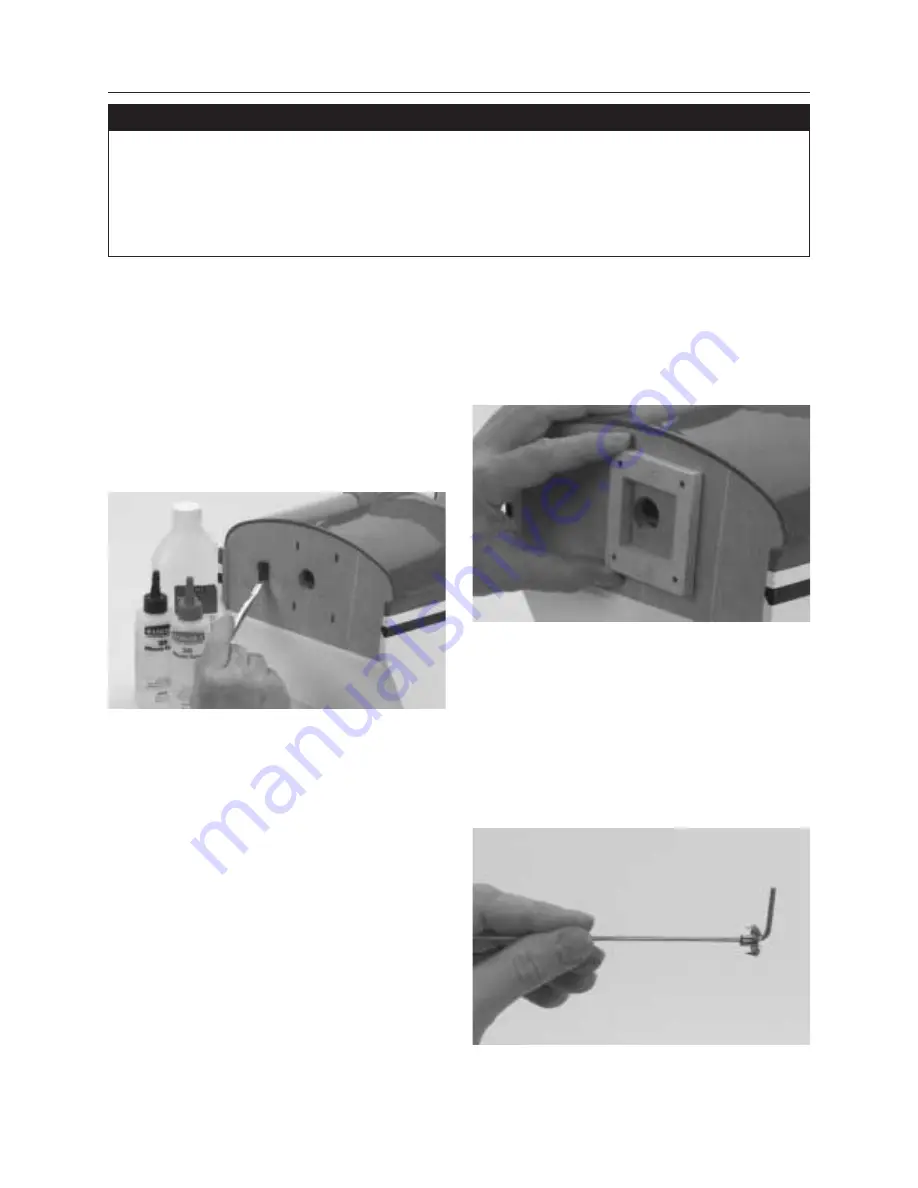

Step 1.

Mix a 50/50 1-ounce mixture of 30-minute epoxy and

rubbing alcohol. Brush it on the entire firewall area to seal it from

fuel. Allow the epoxy to cure completely.

Caution:

Do not get epoxy into any of the predrilled holes.

With some engines like the MDS

™

1.48 engine, you will

need to use the plywood spacer. Be sure to apply the

epoxy/alcohol mix to seal it as well.

Step 2.

Locate the two metal engine mounts and associated

hardware (4 blind nuts, 4.5 mm screws and nuts, 4.5 mm screws

and nuts, and washers). Note the larger screws will be used to

mount the metal motor mount to the firewall.

Step 3.

Before you mount the engine mounts, note there are

slots in the firewall, so the width of the space between the mounts

can be adjusted. This will allow mounting of engines with

different size crankcases. A square 3/4" plywood spacer will be

used to mount some engines (such as the MDS

™

1.48 engine) so

that they are positioned at the proper distance from the firewall as

shown. The Saito™ FA-180 does not require a spacer.

Step 4.

Mount the metal engine mounts on the firewall using

the hardware provided. Do not over-tighten the screws until you

have done a trial fit of the engine on the mount to finalize the

space required.

Note:

It will be necessary to insert a long piece of music

wire (not provided) through the fuselage/firewall and place

a blind nut on the wire so it can be guided into position for

the bottom screw hole in the firewall. Repeat this process

for the other holes.

Summary of Contents for Clipped-wing Taylorcraft

Page 55: ...55 Notes ...