9

Section 2: Joining the Wing Halves

Right/left wing panels

Wing joiner

30-minute epoxy

Epoxy brush

Masking tape

Hobby knife

Rubbing alcohol

Paper towels

Parts Needed

Tools and Adhesives Needed

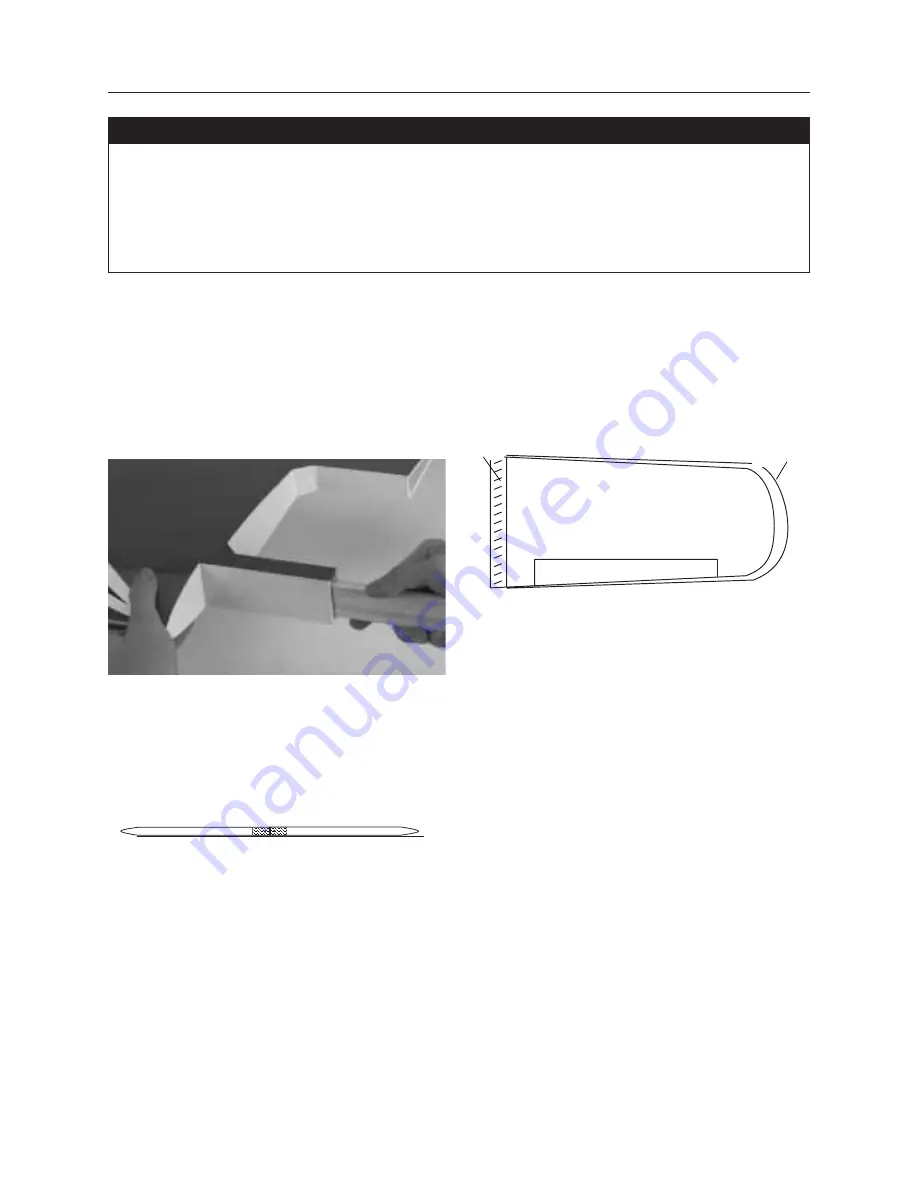

Step 1.

Locate the wing joiner. Using the ruler, determine the

center of the joiner and mark it with a pencil.

Step 2.

Trial fit the wing joiner into one of the wing panels. It

should insert smoothly up to the centerline marked in Step 1.

Now slide the other wing panel onto the wing joiner until the

wing panels meet. If the fit is overly tight, it may be necessary

to sand the wing joiner. Check to make sure the alignment of

the wing is accurate.

Step 3.

The wing has 0° dihedral. Place the wing on a large

flat surface with both wing panels resting on the flat surface.

If necessary, sand the wing joiner until this is achieved. There

should be no gap in the wing center.

Step 4.

Separate the wing halves and remove the wing joiner.

Once you’re satisfied with the trial fit of the wing panels, you can

prepare to epoxy the wing panels together.

Note:

Use the plastic wing covers as a means of keeping

epoxy from smearing on the wings. Slip one on each panel

and use masking tape to hold in place.

Step 5.

Mix an ample amount of 30-minute epoxy. Have some

wax paper handy to prevent epoxy from dripping on your

workbench top.

Note:

It is extremely important to use plenty of epoxy.

Wax paper

Ruler

Pencil

Medium sandpaper

Mixing stick

0

°

Wing Bag

Tape

Summary of Contents for Clipped-wing Taylorcraft

Page 55: ...55 Notes ...