16

EN

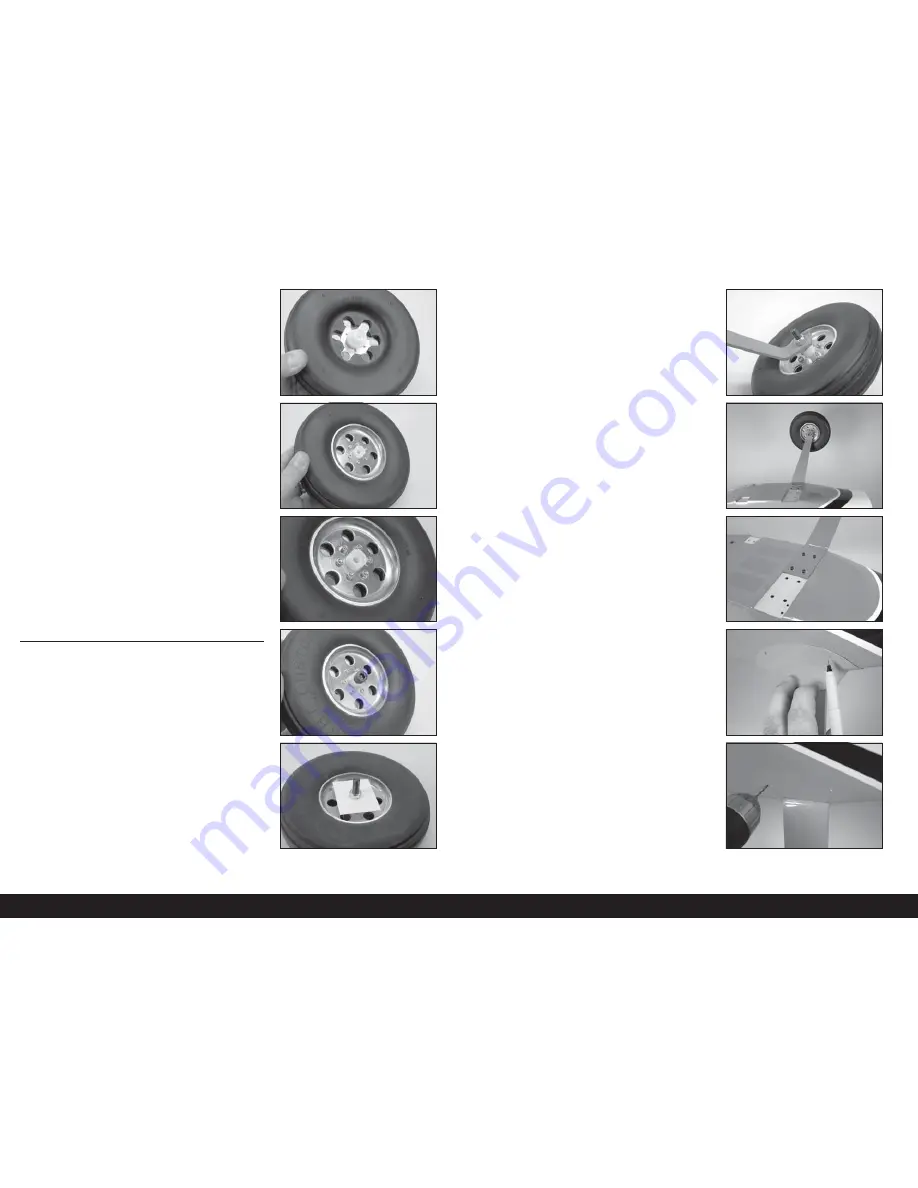

51.

Place the nylon bushing in position in the center of the cover.

52.

Fit the remaining aluminum wheel hub into position, aligning

it with the notches in the tire. Also check to make sure the

holes around the bushing are in alignment.

53.

Secure the hubs using six 4-40 x 3/4-inch stainless socket

head cap screws and six 4-40 lock nuts. Tighten the

hardware using a 3/32-inch hex wrench and 1/4-inch nut

driver. Tighten the hardware evenly so the wheel will run true

when installed on the axles.

55.

Cut a hole in a piece of thin card stock and slide it on the bolt.

Place a drop of threadlock on the bolt near the card stock.

Thread the axle nut on the bolt. Don’t tighten the nut too tight,

preventing the wheel from spinning on the axle bolt.

Allow the threadlock to fully cure before

proceeding. Once cured, remove the card stock

from the bolt without disturbing the nut.

56.

Secure the axle bolt to the landing gear using the axle bolt

lock nut. Use a 6mm hex wrench and 1/2-inch nut driver to

tighten the hardware. Once tightened, make sure the wheel

can spin freely on the axle bolt.

Use a 1/2-inch open end wrench if necessary to hold

the inner nut in position when tightening the hardware.

57.

Check to make sure the landing gear angles toward the front

of the fuselage. The remaining wheel and landing gear strut

can now be installed.

58.

Use four M4 x 25 socket head cap screws and four M4

washers to attach the landing gear to the bottom of the

fuselage. Place a drop of threadlock on each screw before

placing it into position. Tighten the screws using a 3mm hex

wrench.

59.

Fit the landing gear cover to the fuselage. There is a left and

right cover, so check that the cover conforms to the fuselage

and gear. Use a felt-tipped pen to transfer the screw locations

to the fuselage.

STANDARD LANDING GEAR INSTALLATION

54.

Slide the axle bolt into the bushing from the side of the wheel

with the text.

60.

Remove the cover and use a drill and 5/64-inch (2mm) drill

bit to drill the holes for the screws. Thread a screw into each

hole, then remove the screw. Place a few drops of thin CA in

each hole to harden the surrounding wood. Allow the CA to

fully cure before proceeding.