18

EN

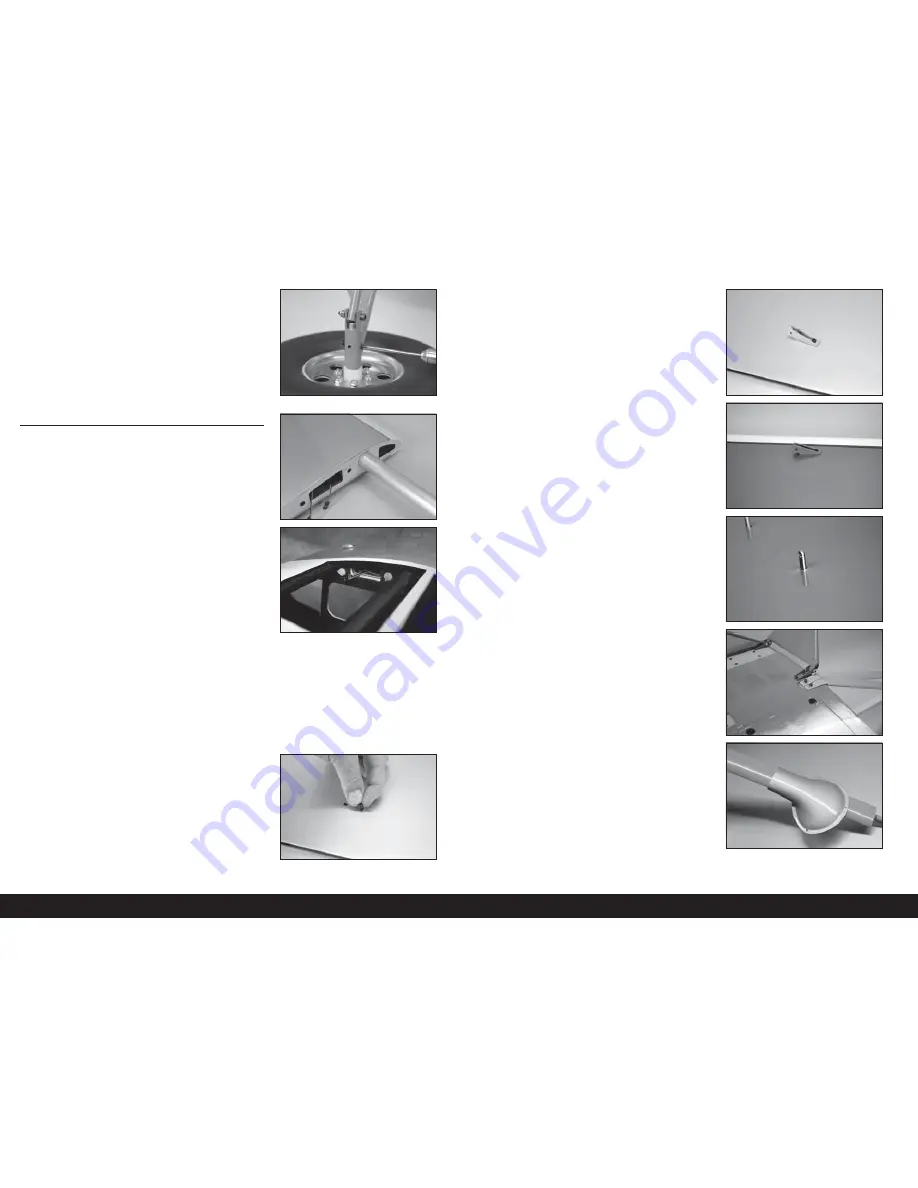

71.

Slide the axle into the main landing gear. Place a drop

of threadlock on the two M3 x 3 setscrews. Thread the

setscrews into the gear, tightening them on the fl at areas of

the axle. Use a 2mm hex wrench to tighten the setscrews.

Use care not to overtighten the

setscrews and damage the threads.

Repeat the previous steps to install the remaining wheel.

WING AND WING STRUT INSTALLATION

72.

Slide the wing tube into the wing tube socket.

The wing tube may be a tight fit in the socket.

Polishing the wing tube with fine sand paper or steel

wool will help ease the installation of the wing tube.

73.

Slide the wing into position on the fuselage. Guide the leads

for the ailerons and fl aps into the fuselage. Secure the wing

to the fuselage using two nylon wing bolts.

The nylon bolt can be shortened to 1

3

/

8

inches

(55mm) to make securing the wing easier.

Repeat the previous steps to attach

the remaining wing panel.

In testing, we found that a single wing bolt near the leading

edge of the wing and the installation of the wing struts was

enough to retain the wings even during sustained aerobatics.

75.

Attach the strut fi tting near the aileron to the bottom of the

wing using two M3 x 15 socket head cap screws. Apply a

drop of threadlock on each screw before tightening them

using a 2.5mm hex wrench.

Do not overtighten the screws and

compress the wing sheeting.

76.

Attach the strut fi tting near the leading edge to the bottom of

the wing using two M3 x 15 socket head cap screws. Apply

a drop of threadlock on each screw before tightening them

using a 2.5mm hex wrench.

Do not overtighten the screws and

compress the wing sheeting.

77.

Thread the jury strut mounts into the holes in the wing. The

base of the mount will be fl ush with the bottom of the wing.

Place a drop of canopy glue on the screws before

installation. This will keep the mounts from vibrating loose.

78.

Attach the wing struts to the fuselage using two M3 x 15

socket head cap screws and two M3 washers. Tighten the

screws using a 2.5mm hex wrench.

Place a drop of canopy glue on the screws before

installation. This will keep the screws from vibrating loose

yet leave them easily removable to disassemble the model.

79.

Slide the outer strut fairing on the strut.

The outer strut fairings are optional as

they are a non-functional scale detail.

74.

Thread an M3 x 15 socket head cap screw into each of the

blind nuts in the bottom of the wing. If any of the screws do

not thread easily, use a 3mm tap to clear the threads.