23

EN

Cub Crafters XCub 60cc

119.

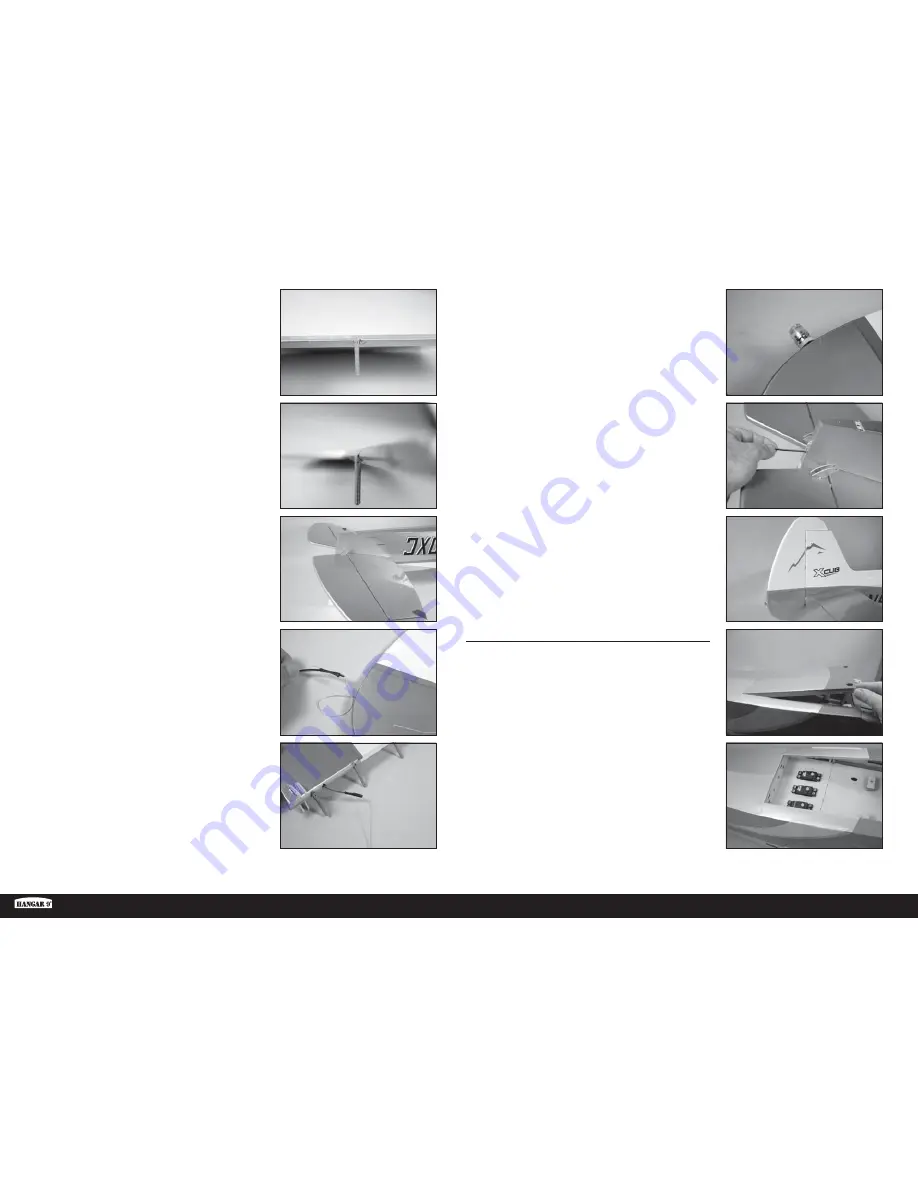

Slide the hinge into position. Position the hinge so it is

perpendicular to the hinge line when fully defl ected.

120.

Insert the hinge so the center of the hinge point aligns with

the front edge of the bevel on the control surface. Check that

the hinge can move freely. Use a paper towel and isopropyl

alcohol to remove any excess epoxy. Allow the epoxy to fully

cure for all hinges before proceeding.

121.

Check the fi t of the hinges from the elevators to the stabilizer.

Once the fi t has been verifi ed, mix 1/2 ounce (15mL) of epoxy.

Apply epoxy to the hinges and pockets in the stabilizer. Fit the

hinges, pressing the elevators fi rmly against the stabilizer.

Use a paper towel and isopropyl alcohol to remove any

excess epoxy. Use low-tack tape to hold the elevators tight

against the stabilizer until the epoxy fully cures.

122.

Tape the string in the rudder to the lead for the position light.

124.

Use a small amount of epoxy of contact adhesive to glue the

position light in the rudder.

125.

Guide the wiring into the fuselage into the cockpit area in the

fuselage.

Attach the wiring to a long piece of wire or tubing

to help guide teh light wire into the fuselage.

RADIO INSTALLATION

127.

Remove the radio hatch cover from the fuselage and place it

in a safe location.

128.

Install the rudder and elevator servos in the fuselage. Make

sure to prepare the servos with the grommets and eyelets.

The mounting holes will need to be drilled and prepared

before the screws can be installed. The rudder servo is the

center servo.

123.

Use the string to pull the wire through the rudder.

126.

Check the fi t of the hinges from the rudder to the fi n. Once

the fi t is verifi ed, mix 15g of epoxy. Apply epoxy to the hinges

and pockets in the fi n. Fit the hinges, pressing the rudder

fi rmly against the fi n. Use a paper towel and isopropyl alcohol

to remove any excess epoxy. Make sure to fully insert the

wire for the navigation light into the fuselage. Allow the epoxy

to fully cure before proceeding.