16

EN

10.

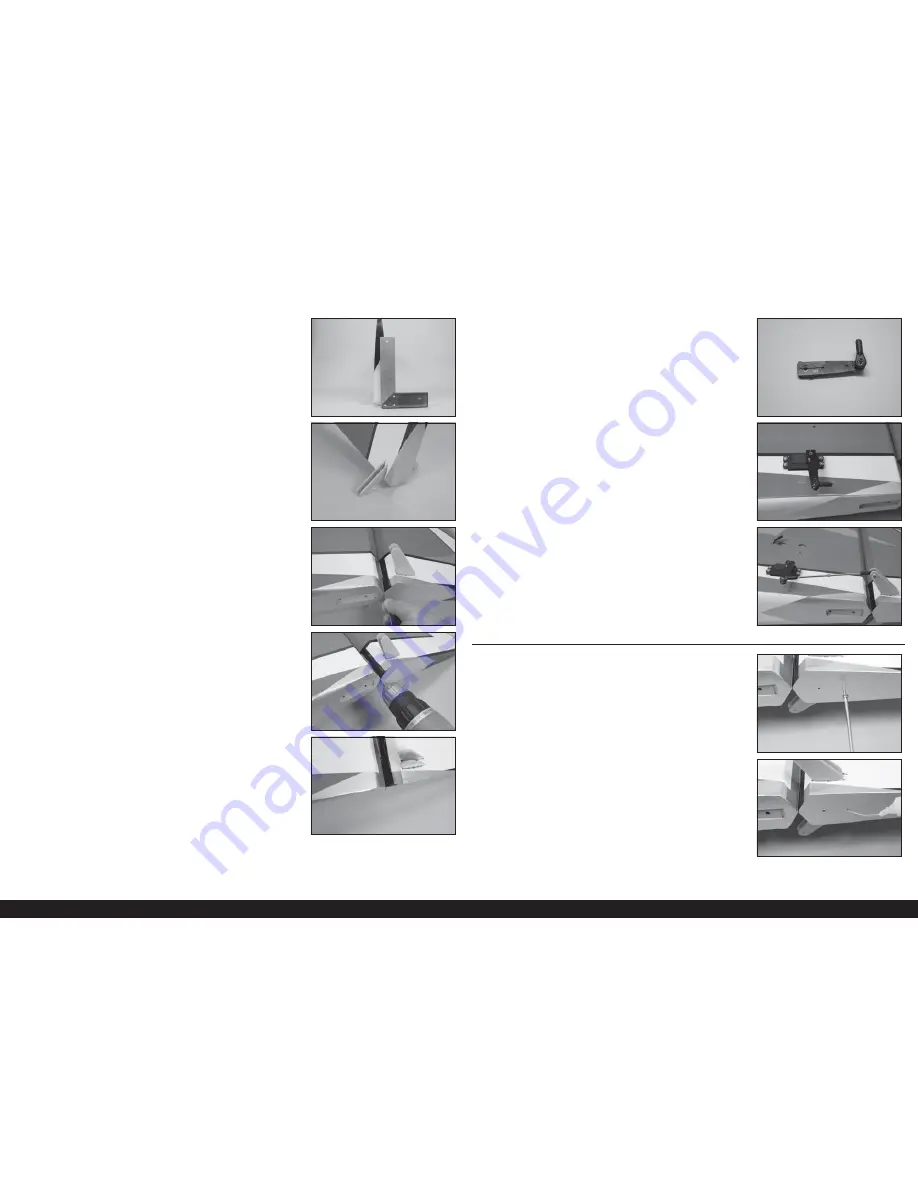

Assemble the rudder linkage using a 4

1

/

2

-inch (114mm)

linkage and ball end. Attach the ball end to the control

horn using a 4-40 x 5/8-inch socket head cap screw and

4-40 locknut. Tighten the hardware using a 3/32-inch

hex wrench and 1/4-inch nut driver. Adjust the linkage so

the rudder is centered while the rudder servo is centered

using the radio system.

1.

Thread a #4 x 5/8-inch self-tapping socket head cap

screw into the two pre-drilled holes in the bottom of the

rudder using a 3/32-inch hex wrench. Remove the screws

before proceeding.

2.

Place 2 to 3 drops of thin CA in each hole to harden

the surrounding wood. Allow the CA to fully cure before

proceeding.

1.

2.

TAIL WHEEL INSTALLATION

5.

Attach the rudder to the fi n using the hinge wire. Start the

wire in the bottom hinge by hand.

6.

Attach a drill to the wire, then use the drill to install the

wire through the remaining hinges.

7.

Complete the hinge wire installation by inserting the wire

so only 1/8-inch (3mm) of the wire protrudes beyond the

bottom of the rudder.

3.

Prepare and install the rudder control horn, starting with

the upper horn. Check that the rudder rests perpendicular

to your work surface when the rudder is resting on the

control horn and hinge line as shown using a square.

8.

Attach the ball link to the rudder servo arm.

4.

Repeat the process to install the lower control horn. Allow

the epoxy to fully cure before proceeding.

9.

Center the rudder servo using the radio system. Attach

the servo arm to the rudder servo perpendicular to the

servo center line.

8.

9.

10.

3.

4.

5.

6.

7.