20

Step 3

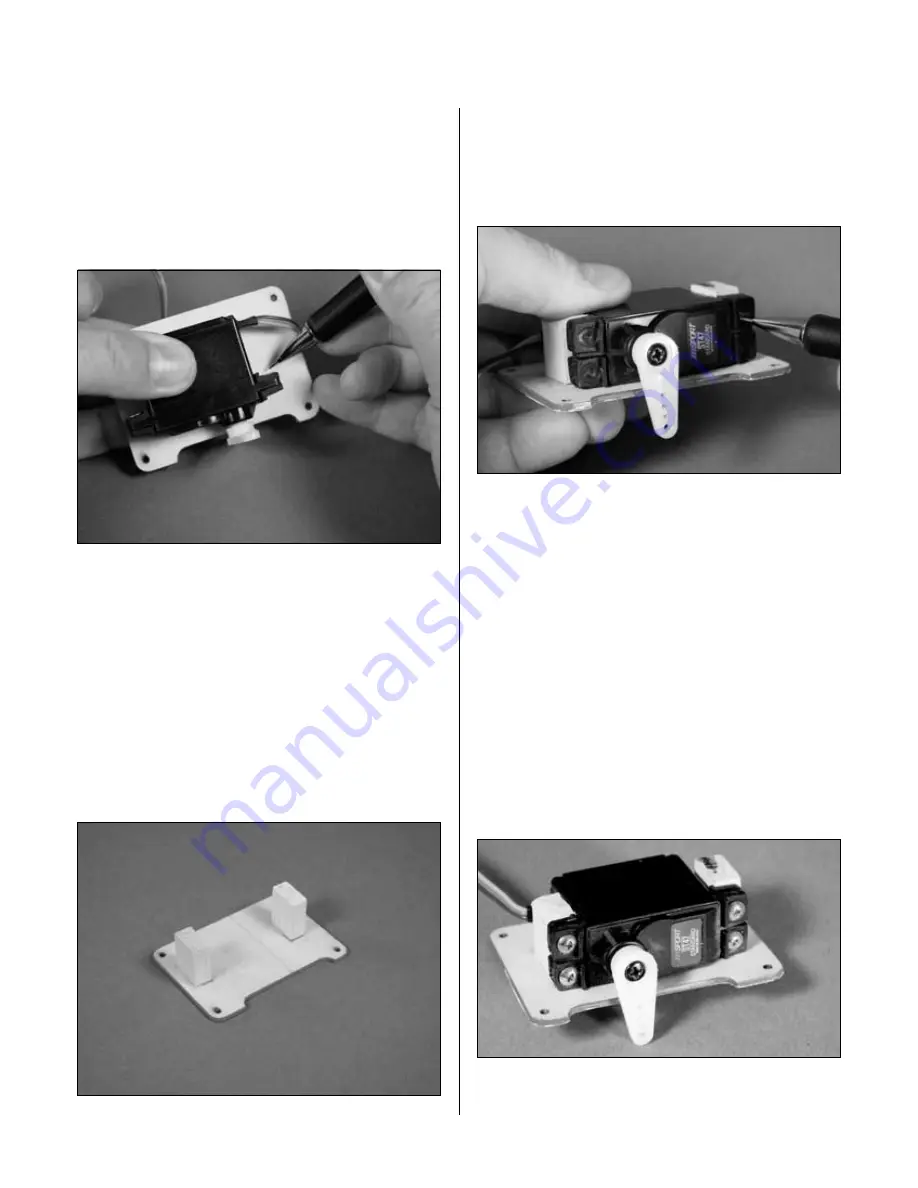

Install the recommended servo hardware (grommets and

eyelets) supplied with the servo. Temporarily install a long

half servo arm (JRPA212) onto the servo and position

the servo onto the hatch so the servo arm is centered in

the notch. Once satisfied, mark the location for the servo

mounting blocks using a felt-tipped pen.

Note

: Check to make sure your servo does

not hang off one end of the servo hatch.

If so, reposition the servo. Having the

servo fully on the hatch is more important

than having the servo arm centered.

Step 4

Locate two 3/8 x 3/4 x 3/4-inch (9.5 x 19 x 19mm) servo

mounting blocks. Use 12-minute epoxy to glue the blocks

to the hatch. Let the epoxy fully cure before proceeding to

the next step.

Step 5

Place the flap servo between the mounting blocks and use

a felt-tipped pen to mark the location of the four servo

mounting screws. Note that the servo must not touch the

hatch in order to isolate engine vibration.

Note

: Before mounting the flap servo, make

sure the servo arm is installed correctly on

the servo. This is done by moving the servo

from each end point to determine the center

position of the servo. With the radio off,

secure the servo arm in the center position.

Check the operation of the servo to determine

if the two end positions of the arm are equal.

If not, reposition the arm as necessary.

Step 6

Remove the servo and use a 1/16-inch (1.5mm) drill bit to

pre-drill the holes for the servo mounting screws marked

in the previous step. Use the screws supplied with the

servo to mount it to the servo mounting blocks.

Section 3: Flap Servo Installation