12

EN

11.

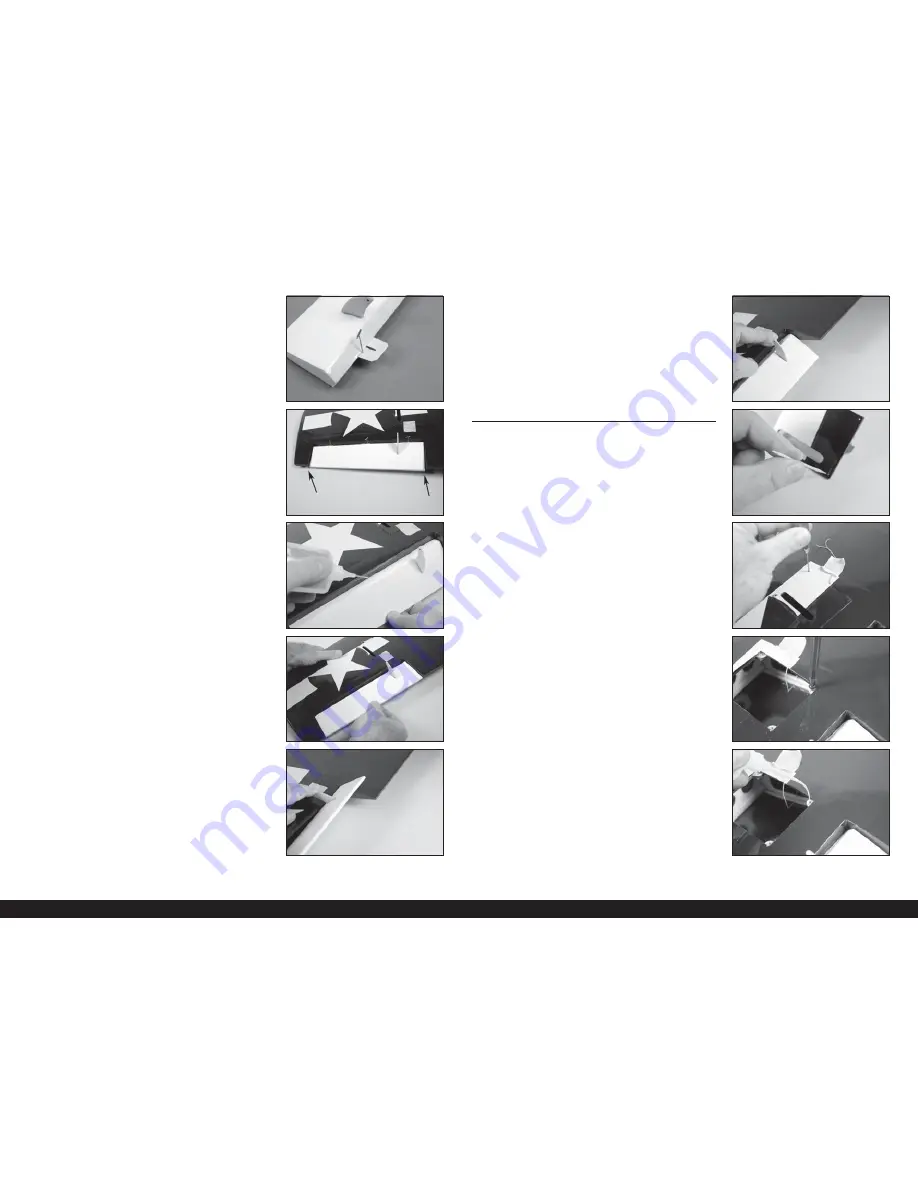

Slide the hinges into position in the aileron with the T-pin

resting against the edge of the control surface.

16.

Check both the up and down movement of the hinges before

proceeding.

Repeat this section for the remaining aileron installation.

12.

Fit the aileron and fl ap to the wing by inserting the hinges into

the slots in the wing. Position the aileron so the gap is equal

between the aileron and wing.

AILERON SERVO INSTALLATION

17.

Remove the aileron servo cover from the wing. Tape the string

to the wing so it won’t fall into the wing. Use a toothpick

or hobby knife to puncture the covering for the servo cover

mounting screws.

13.

Apply thin CA to the top and bottom of each of the hinges.

Make sure to fully soak the hinges so the CA can wick into

the hinge and bond to the surrounding wood.

Use thin CA so it wicks into the hinge. A thicker CA

will not wick into the hinge properly. Do not to allow the

CA to run over the covering on the wing and aileron.

18.

Use a pin vise and 3/32-inch (2.5mm) drill bit to drill the holes

for the servo cover screws.

14.

Allow the CA to cure for 10 to 15 minutes. Gently pull on the

fi xed surface and control surface to make sure the hinges are

glued securely. If not, apply additional CA to secure each of

the hinges.

19.

Use a #2 Phillips screwdriver to thread the M3 x 10 self-

tapping screws into the holes. Remove the screws before

proceeding to the next step.

Do not press down excessively on the

screw as it could damage the structure.

15.

Move the aileron through its range of travel to break in the

hinges.

20.

Apply a small amount of thin CA to harden the threads

made in the previous step. Allow the CA to fully cure before

installing the aileron servo cover.