46

Hangar 9 Funtana 125 ARF Assembly Manual

Elevator Installation

Required Parts

Fuselage assembly

Ball end (2)

Clevis end (2)

4-40 locknut (2)

Carbon stabilizer tube

2mm washer (2)

2mm locknut (2)

2mm x 12mm machine screw (2)

1-inch servo horn (2)

4-40 x 1/2-inch hex head bolt (2)

Threaded pushrod, 5

1

/

2

-inch (146mm)

3mm washer (4)

3mm x 12mm hex head bolt (4)

Tools and Adhesives

Phillips screwdriver: #1

Ruler

Hex wrench: 3/32-inch, 2.5mm

Nut driver: 4mm, 1/4-inch or 5.5mm

Step 1

Locate the items necessary to install the elevator included

with your model.

Step 2

Thread a ball end and clevis on a 5

1

/

2

-inch (146mm)

threaded pushrod. Thread both ends equally on the pushrod.

The overall length of the pushrod will be 7

1

/

8

-inch (181mm)

when assembled.

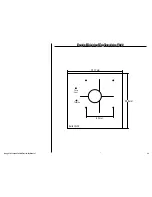

Step 3

Use a 4-40 x 1/2-inch and 4-40 locknut to secure the ball

end to the servo horn. Use a hole that is 1-inch (25mm)

from the center of the horn as shown. Use a 3/32-inch hex

wrench and 1/4-inch nut driver to tighten the hardware.

Note

: We have also included 3mm x 12mm socket

head bolts and 3mm locknuts if you are not using JR or

Hangar 9 servo horns on your model. Use a 2.5mm hex

wrench and 5.5mm nut driver to tighten this hardware.

Step 4

Use the radio system to center the elevator servo. Use

the hardware included with the servo (and servo horn if

applicable) to secure the servo horn to the elevator servo.

Make sure the horn is perpendicular to the center line of the

servo.

Step 5

Repeat Steps 2 through 4 to prepare the linkage for the

servo on the opposite side of the fuselage.