Section 3 – Aileron Control Horn Installation

9

Required Parts

• Wing panel (left and right)

• Aileron (left and right)

• 4-40 x 1/2" screw (2)

• 4-40 lock nut (2)

• Tapered standoff (2)

• Threaded metal clevis (2)

• Clevis retainer (2)

• Nylon ball link (2)

• 4-40 x 2

3

/

4

" threaded rod (2)

• 4-40 nut (2)

• Nylon control horn (2)

• 2mm x 20mm self-tapping screw (6)

Required Tools and Adhesives

• Felt-tipped pen

• Threadlock

• Drill

• Drill bit: 1/16"

• Square

• Ruler

• Phillips screwdriver (small)

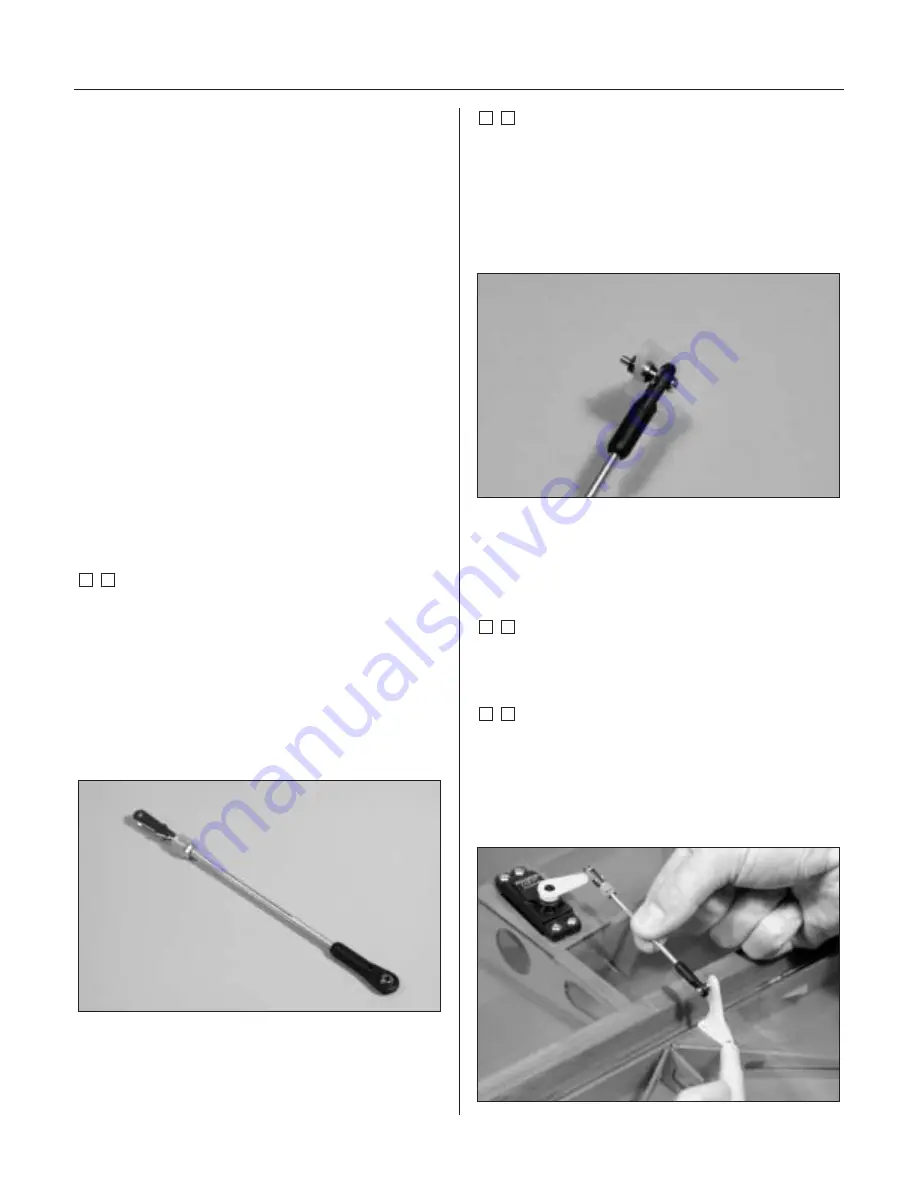

Step 1

Locate the metal clevis 4-40 nut, clevis retainer and

nylon ball link. Thread the 4-40 nut onto one end of a 4-

40 x 2

3

/

4

" threaded rod. Slice a clevis retainer onto a

metal clevis and thread the clevis up against the nut. A

small amount of the rod will be visible between the forks

of the clevis. Tighten the nut against the clevis to prevent

it from loosening. Thread the nylon ball end onto the

other end of the threaded rod.

Note

: It is suggested that threadlock be used

on the nut and clevis to prevent them from

loosening during flight.

Step 2

Remove the backplate from one of the large control

horns. Attach the ball end to the center hole of the

control horn using a 4-40 x 1/2" screw, tapered standoff

and 4-40 lock nut. The standoff is positioned between

the ball end and control horn, which allows for smooth

operation of the linkage.

Note

: Attach the ball end so it will be

on the side of the control horn closest to

the wing tip.

Step 3

Attach a heavy-duty servo arm to the servo. Position the

arm parallel to the aileron hinge line.

Step 4

Position the control horn on the aileron so all three of the

mounting holes are centered on the mounting block. Also

check to make sure the linkage is at a 90-degree angle

to the servo arm. Transfer the location of the control

horn mounting holes onto the aileron.