26

Hangar 9 Toledo Special Assembly Manual

Step 2

Check the fit of the windows in the sides of the fuselage. The

windows fit on the inside of the fuselage to hide the edges.

Once the right and left windows have been determined, use

canopy glue to glue the windows in the fuselage sides. Use low-

tack tape to keep the windows in position until the glue cures.

Step 3

The windshield is installed in the same manner as the side

windows. Once everything has been placed, set the fuselage

aside to allow the glue to fully cure.

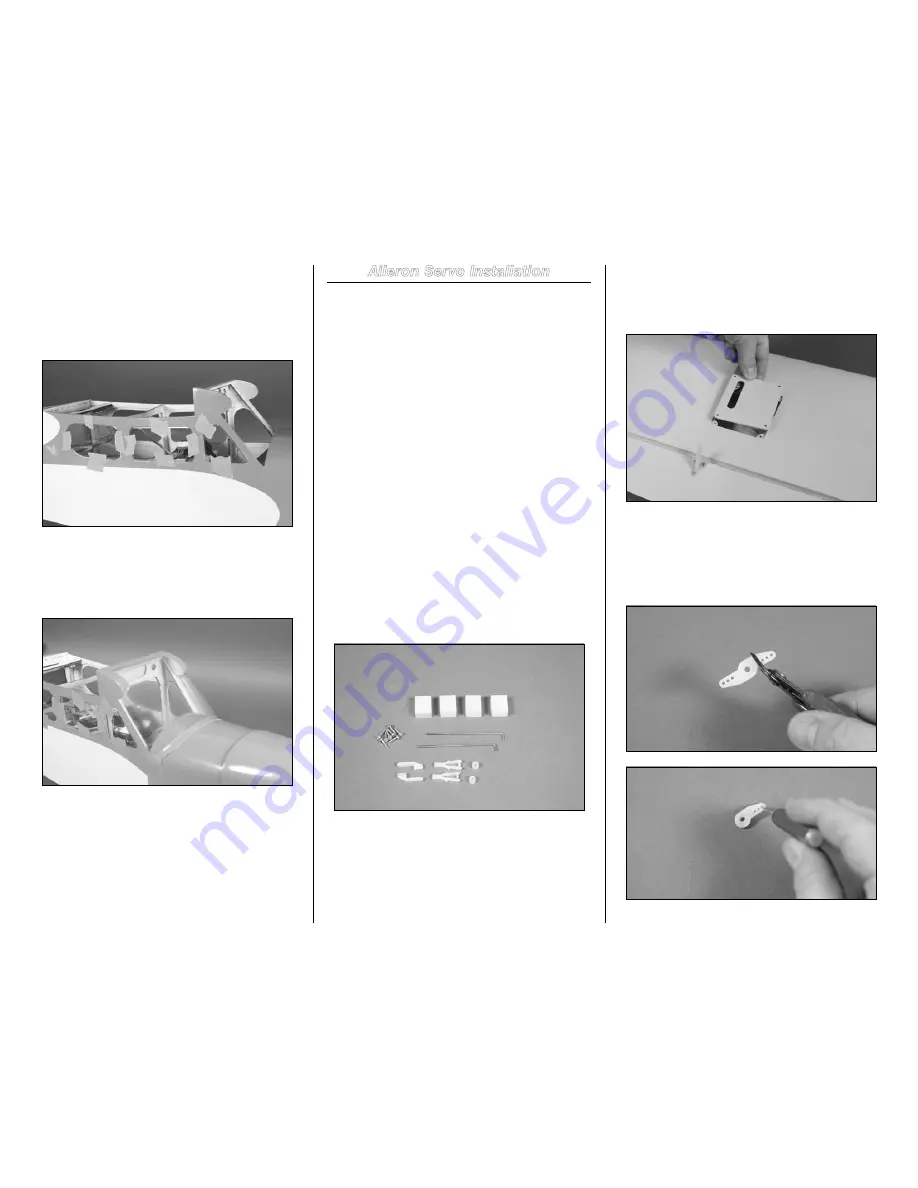

Aileron Servo Installation

Required Parts

Wing panel (right and left)

Clevis (2)

Clevis retainer (2)

Pushrod keeper (2)

Servo with hardware (2)

9-inch (228mm) servo extension (2)

Aileron servo mounting blocks (4)

2

7

/

8

-inch (73mm) pushrod wire (2)

#4 x 1/2-inch sheet metal screw (8)

Tools and Adhesives

Phillips screwdriver: #1

30-minute epoxy

Mixing sticks

Mixing cup

Drill

Pencil

Ruler

Thin CA

Small clamps

Medium grit sandpaper

Drill bit: 1/16-inch (1.5mm), 5/64-inch (2mm)

Step 1

Locate the items necessary to install the aileron servos in

the wing. Most items are from the bag marked wing. You will

also need the aileron pushrod wires from the bag marked

pushrod.

Step 2

Remove the servo cover for the aileron from the wing panel.

Note the location of the servo horn exit on the cover and

how it aligns with the control horn.

Step 3

Prepare a 180-degree servo horn by removing one of the

arms from the horn as show. Use a pin drill and 5/64-inch

(2mm) drill bit to enlarge the outer hole that is 9/16-inch

(15mm) from the center of the arm.