16

EN

4.

5.

6.

7.

8.

4.

5.

1.

2.

3.

4.

Use an epoxy brush to apply epoxy to the exposed wood

on the base of the fi n where it contacts the fuselage.

5.

Fit the fi n back into position. Use a paper towel and

isopropyl alcohol to remove any excess epoxy from

the fi n and fuselage. Use low-tack tape to hold the fi n

securely in position while the epoxy fully cures. Slide the

hinge pin into position to secure the lower rudder hinge.

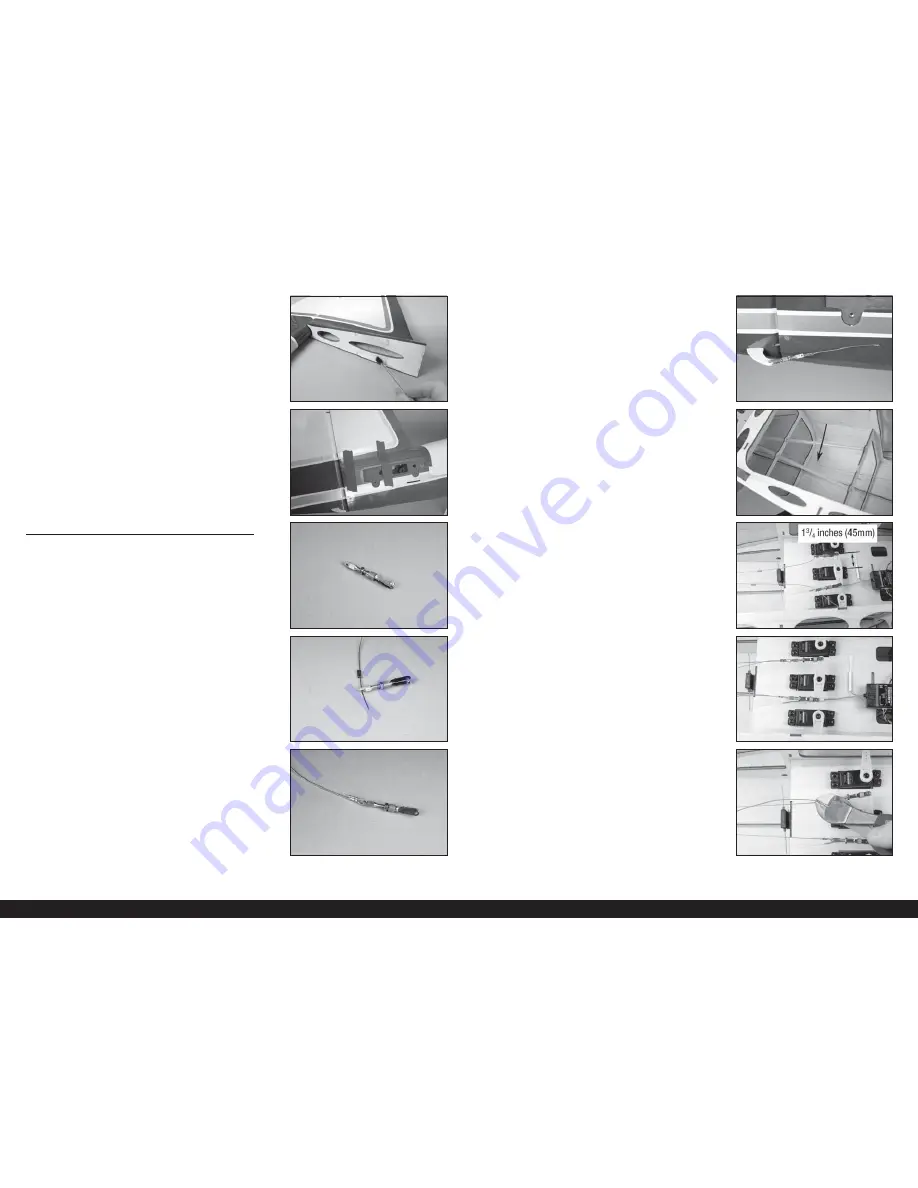

RUDDER CABLE INSTALLATION

1.

Slide a clevis retainer on the barrel portion of the clevis.

Thread an M2 nut on the cable end, then thread the

cable end into the clevis until it is visible between the

forks of the clevis. Prepare all four clevises at this time.

2.

Slide a sleeve on the cable, then the cable through the

cable end.

3.

Loop the cable back through the sleeve. Use a crimping

tool to secure the sleeve to the cable.

4.

Attach the clevis to the rudder control horn, then insert

the cable into the tube in the fuselage. Guide the cable to

toward the rudder servo. Install both cables at this time.

5.

When routing the cables to the servo, they will cross

inside the fuselage as shown.

6.

Attach the two remaining clevises to the rudder servo

arm. Slide a sleeve on the cable, then slide the cable

through the cable end. The clevis will attach to the arm

1

3

/

4

inches (45mm) on either side from the center of the

arm.

7.

Slide the cable back through the sleeve. Tighten the

rudder cables so there is light tension on both cables.

The rudder and rudder servo should also be centered at

this time.

8.

Use a crimping tool to secure the sleeve to the cables.

Use side cutters to trim the excess cable.

Check the tension on the cables periodically

and adjust if they become slack.