51

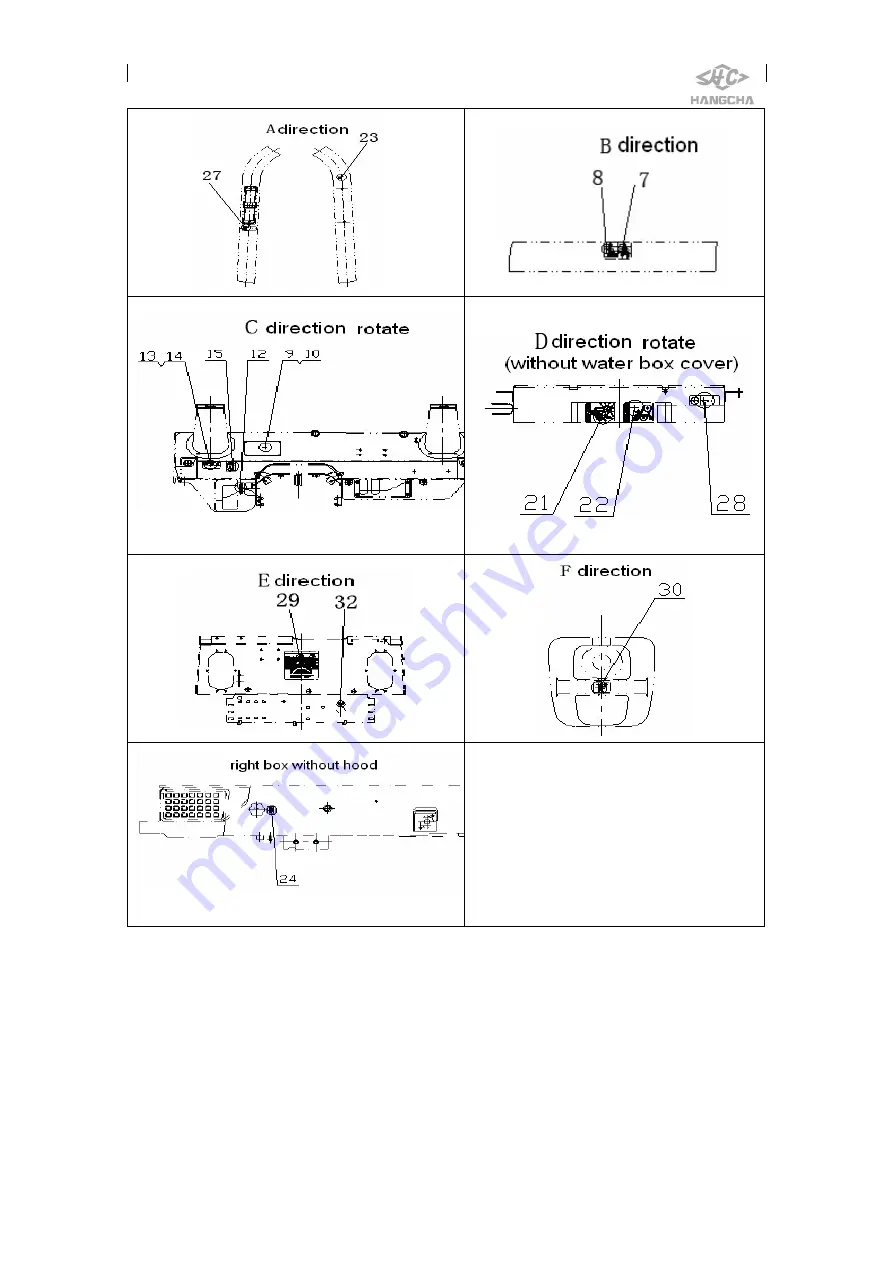

1. typeface label 2. danger label 3.fuse label 4. diesel label 5.gasoline label

6. Tonnage label 7. Danger label 8. Danger label 9. Product nameplate

11. Safety belt label 12. Shift label 13. Operate label 14. Operate label

15. Hand brake label 16. Load curve scutcheon 17. Load curve scutcheon

18. Load curve scutcheon 19.warning label 21. Fan cuts hand label

22. Belt nips hand label 23. Noise label 24. Hydraulic oil label

25. Hanging label 26. CE label 27.no water flushing label 28. Antifreeze label

29. Lubrication system label 30. Tight point label 31. Air pressure label

32. Horn label 33.LPG label