37

2. Weekly maintenance

(

40hours

)

Increase the following content based on daily

maintenance.

1. Air cleaner maintenance

General condition

:

Perform maintenance on the air cleaner after

50-250 hours of operation.

Replace air cleaner after maintaining for six

times.

Caution

If the working condition is bad, air cleaner

needs to be serviced/replaced more

frequently.

Under dusty work conditions, the cycle of

maintaining and changing air cleaner will be

shortened.

It

is

advised

to

perform

maintenance between 8-50 hours; replace it

between 100-300 hours.

Maintenance method

:

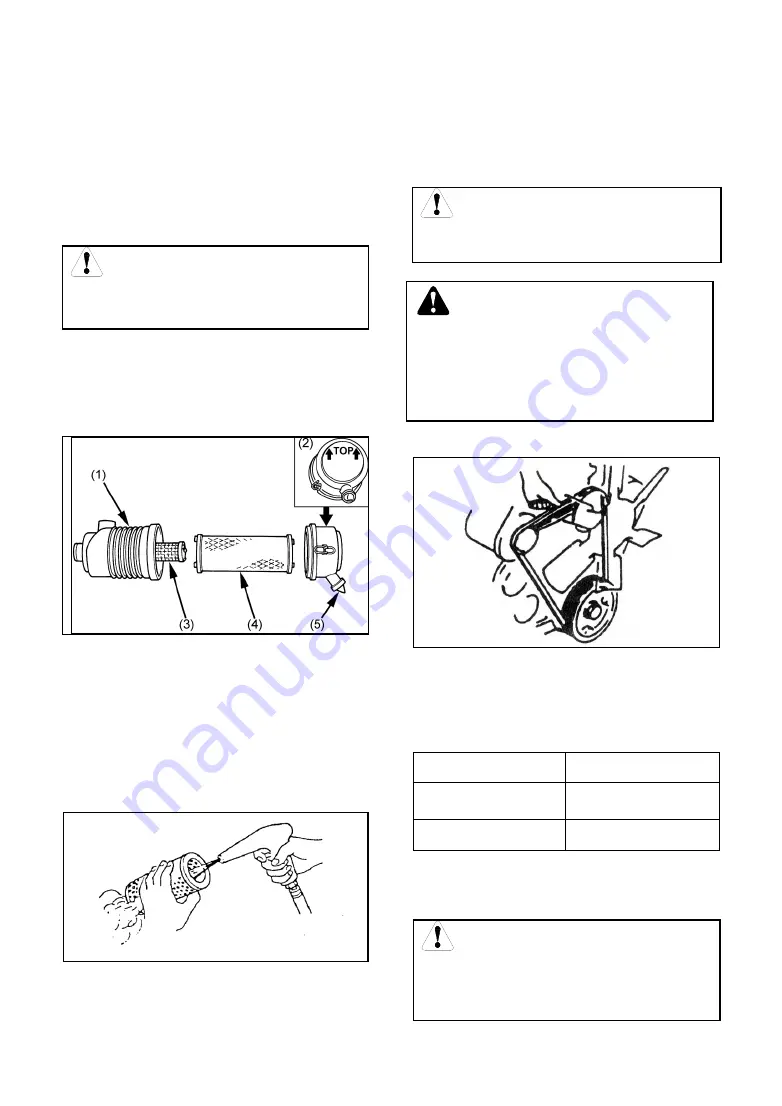

(1) Air cleaner body (2) Dust cup

(3) Secondary element (4) Primary element

(5) Evacuator valve

①

Open the evacuator valve once a week

under ordinary conditions - or daily when

used in a dusty place. This will get rid of

large particles of dust and dirt.

②

Wipe the inside air cleaner clean

with cloth if it is dirty or wet.

①

Dismantle filter end cap;

②

Take out the filter element;

③

Main filter (outer filter) Blow off the

dust inner and outer of the outer

filter element with dry compressed

air.

④

Safety filter element (inner filter):

hand beat clean, avoid blowing with

air. Special attention.

⑤

Caution

Pressure of compressed air must be under

205 kPa (2.1 kgf/cm , 30 psi)

Warning

1. Dust will blow into your eyes, so please

wear protective glasses.

2. Do not maintain and replace element

filter in time according to the requirement

will lead to the damage of engine in

advance.

2. Fan belt

Stop the engine.

Use finger to press the belt at the midway

point between the water pump pulley and the

generator pulley by 10kg press, and check

the drop distance if it is up to standard.

Engine

Drop distance

(

mm

)

4TNE92

4TNE98

New 8-12(

<

5min)

old 10-

14(≥5min)

V2607-CR-TE5B

10 - 12

Cummins QSF2.8 engines equip with

automatic tensioning pulley, and their fan belt

tension do not need adjust.

Caution

If the belt is loose, cut out, or has no surplus

it should be changed.

DO NOT perform this check with the engine

running to avoid personal injury.