11

3 Safety Instructions

1)

Only trained and authorized operator

shall be permitted to operate the truck.

2)

Operator must wear helmet, working

shoes and uniform

3)

Do not overload.

4)

Never carry people.

5)

It is not allowed to reconfigure the truck

without manufacturer’s permission.

6)

Do not work in flammable and

combustible environment.

7)

Check the oil, fluid leakage, deformation,

flexibility in certain time. If neglected,

service life of forklift will be shorted and

in serious condition there will be

accident.

–

Make sure change the “safety parts”

during the schedule maintenance.

–

Wipe off the oil, grease or water on the

soleplate, foot pedal and control lever.

–

No smoking or any spark, smoke near

the battery when checking.

–

Be careful of scald when checking motor

and controller.

8)

The controller equips with energy

accumulator, do not touch between B+

and B- to avoid electric injury. If you

need check or clean the controller,

connect load(like contactor coil or horn

or bulb or resistance) between

controller B+ and B- to discharge the

controller capacity.

9)

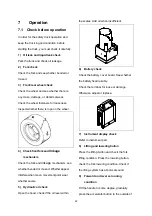

Whenever you find the forklift abnormal,

stop the truck, put on the DANGEROUS

or FAULT sign to the truck, remove the

key, and report to the managing person.

Only after eliminating the fault can you

30 5W

Summary of Contents for Mini Series

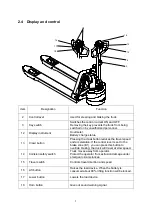

Page 24: ...20 Fuse LED2 charging status indicator LED1 power indicator ...

Page 45: ...41 ...

Page 58: ...54 2 Hydraulic system 2 1 Hydraulic system working principle ...

Page 60: ...56 3 Electric system 3 1 Electrical schematic diagram ...

Page 65: ...Maintenance Record Date Repair maintenance content Serviceman ...