66

new brake fluid as the level drops.

Caution

Prevent dust and water from mixing with the

brake fluid when adding it.

Brake fluid is toxic and corrosive and should

be rinsed off if you are exposed to it.

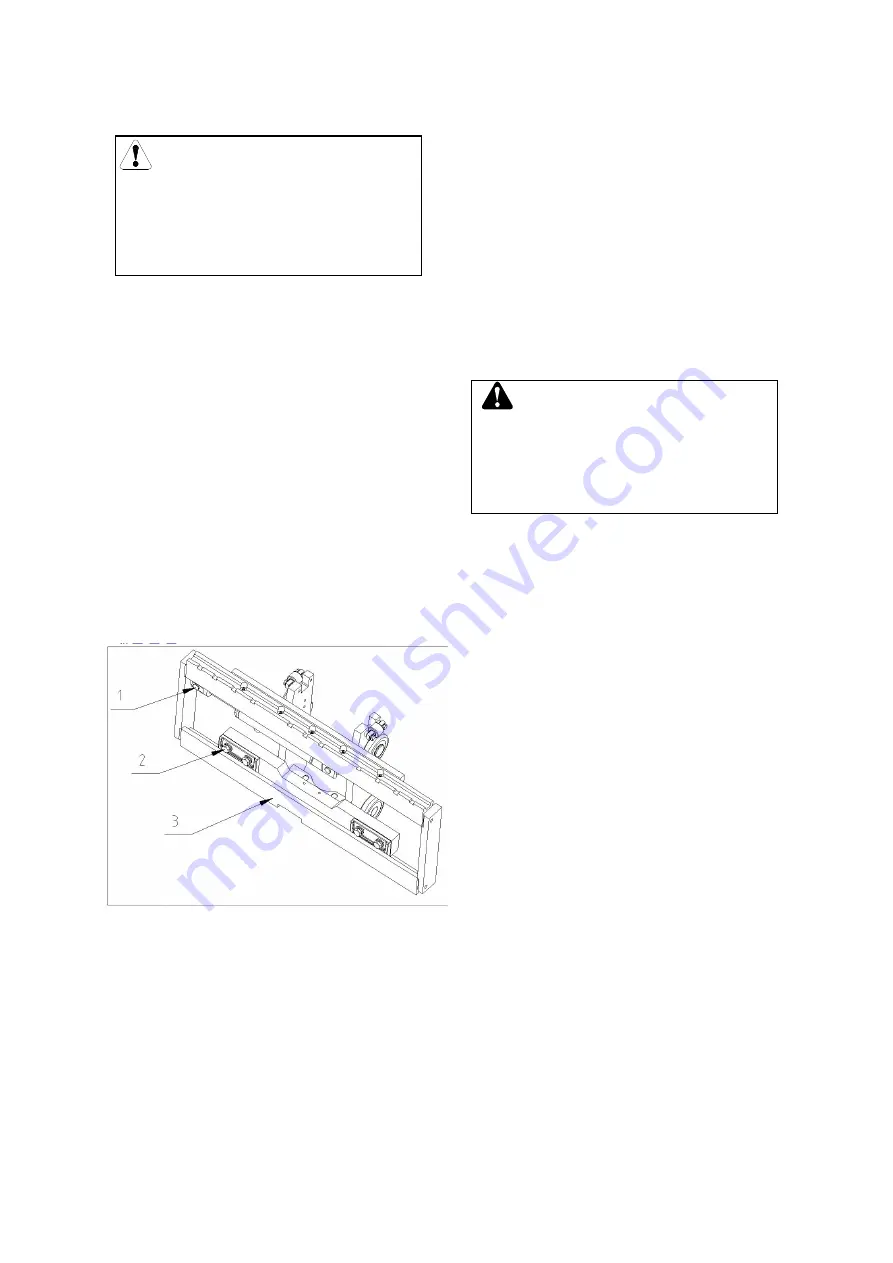

3. Check the built-in friction block in the side

shifter

1. Remove the pin at the piston rod end of

the side-shifting cylinder.

2. Remove the four bolts of the left, right and

down friction blocks, and remove the down

friction block (pay attention to the

adjustment pad inside).

3. Push the beam under the side-shifting

frame forward slightly and lift the

side-shifting frame upwards.

4. Check the thickness of the friction block

and replace the friction block with a new one

when the wear relative to the initial size is

greater than 2 mm.

6.6 Annual maintenance (2,000

hours)

Add the following maintenance items in addition

to the semi-annual maintenance.

1. Change the front wheel bearing lubricating

grease

Refer to the drive axle hub content in the

Maintenance Manual, disassemble the wheel

bearing, and then change the grease.

2. Change the rear wheel bearing lubricating

grease

Refer to the content on the steering axle in the

Maintenance Manual.

3. Change the lubricating grease for the entire

forklift truck

4. Replace the hydraulic oil

Warnings

Hot hydraulic oil and components may scald

the human body. Do not touch hot

hydraulic oil or associated components.

Operating steps:

–

Park the truck according to rules and

regulations.

–

Tilt the mast to its limit and lower the

forks to the ground.

–

Remove the rubber pad from the base

plate.

–

Remove the rear base plate.

–

Unscrew the hydraulic oil tank lid and

dipstick assembly.

–

Place an oil container under the frame,

unscrew the oil drain plug and sealing gasket,

and drain out the old oil;

–

Take away the oil container, handle the

waste oil according to local environmental

regulations, do not dump it arbitrarily;

–

Screw in the oil drain plug and sealing

gasket, add new hydraulic oil, check whether

there is leakage;

–

Start the forklift truck, lift the forks 3 - 5